Paper:

Mechanical and Geometric Constraints for Robotic Assembly with a Single Manipulator

Satoshi Makita

and Yuya Honda

and Yuya Honda

Fukuoka Institute of Technology

3-30-1 Wajiro-higashi, Higashi-ku, Fukuoka, Fukuoka 811-0295, Japan

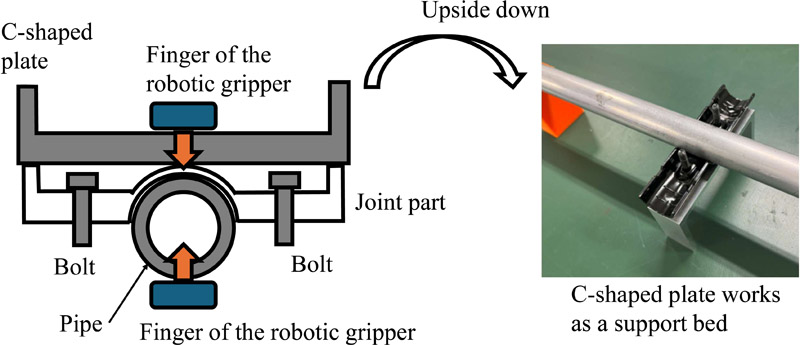

This study investigated an assembly strategy that leverages only a single robotic manipulator and an attached parallel gripper. This approach reduces the need for additional fixtures, such as manipulators and fixturing jigs, and minimizes costs and workspace footprint. We discuss the mechanical and geometric conditions required to improve the robustness of objects in the assembly process. The mechanical conditions represent the force equilibrium of multiple objects, and the geometric conditions restrict the movability of the objects. As some of the support jigs used in the experiments were not controlled to firmly fix the assembled objects, the above conditions were essential to guarantee the robustness of the temporarily assembled parts. This paper presents a successful case of automated assembly using a single manipulator, demonstrating the potential of the proposed method.

Handling temporarily assembled objects

- [1] R. A. Knepper, T. Layton, J. Romanishin, and D. Rus, “Ikeabot: An autonomous multi-robot coordinated furniture assembly system,” IEEE Int. Conf. on Robotics and Automation, pp. 855-862, 2013. https://doi.org/10.1109/ICRA.2013.6630673

- [2] A. Keshvarparast, D. Battini, O. Battaia, and A. Pirayesh, “Collaborative robots in manufacturing and assembly systems: Literature review and future research agenda,” J. of Intelligent Manufacturing, Vol.35, pp. 2065-2118, 2023. https://doi.org/10.1007/s10845-023-02137-w

- [3] E. Rimon and A. Blake, “Caging 2D bodies by 1-parameter two-fingered gripping systems,” Proc. of IEEE Int. Conf. on Robotics and Automation, pp. 1458-1464, 1996. https://doi.org/10.1109/ROBOT.1996.506911

- [4] S. Makita and W. Wan, “A survey of robotic caging and its applications,” Advanced Robotics, Vol.31, Issues 19-20, pp. 1071-1085, 2017. https://doi.org/10.1080/01691864.2017.1371075

- [5] S. Alatartsev, S. Stellmacher, and F. Ortmeier, “Robotic task sequencing problem: A survey,” J. of Intelligent and Robotic Systems: Theory and Applications, Vol.80, pp. 279-298, 2015. https://doi.org/10.1007/s10846-015-0190-6

- [6] W. Wan, K. Harada, and K. Nagata, “Assembly sequence planning for motion planning,” Assembly Automation, Vol.38, Issue 2, pp. 195-206, 2018. https://doi.org/10.1108/AA-01-2017-009

- [7] T. Murayama, B. Takemura, and F. Oba, “Assembly sequence planning using inductive learning,” J. Robot. Mechatron., Vol.11, No.4, pp. 315-320, 1999. https://doi.org/10.20965/jrm.1999.p0315

- [8] C. Li and W. Hou, “Assembly sequence planning based on hierarchical model,” Wireless Communications and Mobile Computing, Vol.2022, No.1, Article No.9461794, 2022. https://doi.org/10.1155/2022/9461794

- [9] I. Nishida, H. Sawada, and K. Shirase, “Automated generation of product assembly order based on geometric constraints between parts,” Int. J. Automation Technol., Vol.17, No.2, pp. 167-175, 2023. https://doi.org/10.20965/ijat.2023.p0167

- [10] X. Jiang, K.-M. Koo, K. Kikuchi, A. Konno, and M. Uchiyama, “Robotized assembly of a wire harness in a car production line,” Advanced Robotics, Vol.25, Issues 3-4, pp. 473-489, 2011. https://doi.org/10.1163/016918610X551782

- [11] T. Yoshikawa, “Manipulability and redundancy control of robotic mechanisms,” Proc. of 1985 IEEE Int. Conf. on Robotics and Automation, Vol.2, pp. 1004-1009, 1985. https://doi.org/10.1109/ROBOT.1985.1087283

- [12] T. Yoshikawa, “Manipulability of robotic mechanisms,” Int. J. of Robotics Research, Vol.4, Issue 2, pp. 439-446, 1985. https://doi.org/10.1177/027836498500400201

- [13] F. Suárez-Ruiz and Q.-C. Pham, “A framework for fine robotic assembly,” IEEE Int. Conf. on Robotics and Automation, pp. 421-426, 2016. https://doi.org/10.1109/ICRA.2016.7487162

- [14] R. Ozawa and K. Tahara, “Grasp and dexterous manipulation of multi-fingered robotic hands: A review from a control view point,” Advanced Robotics, Vol.31, Issues 19-20, pp. 1030-1050, 2017. https://doi.org/10.1080/01691864.2017.1365011

- [15] A. M. Okamura, N. Smaby, and M. R. Cutkosky, “An overview of dexterous manipulation,” Proc. of IEEE Int. Conf. on Robotics and Automation, pp. 255-262, 2000. https://doi.org/10.1109/ROBOT.2000.844067

- [16] A. Billard and D. Kragic, “Trends and challenges in robot manipulation,” Science, Vol.364, No.6446, Article No.eaat8414, 2019. https://doi.org/10.1126/science.aat8414

- [17] M. R. Pedersen, L. Nalpantidis, R. S. Andersen, C. Schou, S. Bøgh, V. Krüger, and O. Madsen, “Robot skills for manufacturing: From concept to industrial deployment,” Robotics and Computer-Integrated Manufacturing, Vol.37, pp. 282-291, 2016. https://doi.org/10.1016/j.rcim.2015.04.002

- [18] Y. Wang, K. Harada, and W. Wan, “Motion planning through demonstration to deal with complex motions in assembly process,” 2019 IEEE-RAS 19th Int. Conf. on Humanoid Robots (Humanoids), pp. 544-550, 2019. https://doi.org/10.1109/Humanoids43949.2019.9035043

- [19] Z. Zhu and H. Hu, “Robot learning from demonstration in robotic assembly: A survey,” Robotics, Vol.7, Issue 2, Article No.17, 2018. https://doi.org/10.3390/robotics7020017

- [20] H. Park, J. Park, D. H. Lee, J. H. Park, M. H. Baeg, and J. H. Bae, “Compliance-based robotic peg-in-hole assembly strategy without force feedback,” IEEE Trans. on Industrial Electronics, Vol.64, Issue 8, pp. 6299-6309, 2017. https://doi.org/10.1109/TIE.2017.2682002

- [21] J. D. Lane, “Evaluation of a remote center compliance device,” Assembly Automation, Vol.1, Issue 1, pp. 36-46, 1980. https://doi.org/10.1108/eb004135

- [22] D. E. Whitney, “Quasi-static assembly of compliantly supported rigid parts,” J. of Dynamic Systems, Measurement, and Control, Vol.104, Issue 1, pp. 65-77, 1982. https://doi.org/10.1115/1.3149634

- [23] S. Lee, “Development of a new variable remote center compliance (VRCC) with modified elastomer shear pad (ESP) for robot assembly,” IEEE Trans. on Automation Science and Engineering, Vol.2, Issue 2, pp. 193-197, 2005. https://doi.org/10.1109/TASE.2005.844437

- [24] D. I. Park, H. Kim, C. Park, T. Choi, H. Do, B. Kim, and J. Park, “Automatic assembly method with the passive compliant device,” 2017 11th Asian Control Conf. (ASCC), pp. 347-348, 2017. https://doi.org/10.1109/ASCC.2017.8287193

- [25] S. Choi, D. Kim, Y. Kim, Y. Kang, J. Yoon, and D. Yun, “A novel compliance compensator capable of measuring six-axis force/torque and displacement for a robotic assembly,” IEEE/ASME Trans. on Mechatronics, Vol.29, Issue 1, pp. 29-40, 2024. https://doi.org/10.1109/TMECH.2023.3294510

- [26] J. Takahashi, T. Fukukawa, and T. Fukuda, “Passive alignment principle for robotic assembly between a ring and a shaft with extremely narrow clearance,” IEEE/ASME Trans. on Mechatronics, Vol.21, Issue 1, pp. 196-204, 2016. https://doi.org/10.1109/TMECH.2015.2448639

- [27] D. Sanchez, W. Wan, and K. Harada, “Four-arm collaboration: Two dual-arm robots work together to manipulate tethered tools,” IEEE/ASME Trans. on Mechatronics, Vol.27, Issue 5, pp. 3286-3296, 2022. https://doi.org/10.1109/TMECH.2021.3106644

- [28] Z. Hu, W. Wan, and K. Harada, “Designing a mechanical tool for robots with two-finger parallel grippers,” IEEE Robotics and Automation Letters, Vol.4, Issue 3, pp. 2981-2988, 2019. https://doi.org/10.1109/LRA.2019.2924129

- [29] J. Shintake, V. Cacucciolo, D. Floreano, and H. Shea, “Soft robotic grippers,” Advanced Materials, Vol.30, Issue 29, Article No.1707035, 2018. https://doi.org/10.1002/adma.201707035

- [30] Y. Yokokohji, Y. Kawai, M. Shibata, Y. Aiyama, S. Kotosaka, W. Uemura, A. Noda, H. Dobashi, T. Sakaguchi, and K. Yokoi, “Assembly challenge: A robot competition of the industrial robotics category, world robot summit—Summary of the pre-competition in 2018,” Advanced Robotics, Vol.33, Issue 17, pp. 876-899, 2019. https://doi.org/10.1080/01691864.2019.1663609

- [31] K. Nie, F. von Drigalski, J. C. Triyonoputro, C. Nakashima, Y. Shibata, Y. Konishi, Y. Ijiri, T. Yoshioka, Y. Domae, T. Ueshiba, R. Takase, X. Zhang, D. Petit, I. G. Ramirez-Alpizar, W. Wan, and K. Harada, “Team O2AS’ approach for the task-board task of the world robot challenge 2018,” Advanced Robotics, Vol.34, Issues 7-8, pp. 477-498, 2020. https://doi.org/10.1080/01691864.2020.1738270

- [32] S. Tajima, S. Wakamatsu, T. Abe, M. Tennomi, K. Morita, H. Ubata, A. Okamura, Y. Hirai, K. Morino, Y. Suzuki, T. Tsuji, K. Yamazaki, and T. Watanabe, “Robust bin-picking system using tactile sensor,” Advanced Robotics, Vol.34, Issues 7-8, pp. 439-453, 2020. https://doi.org/10.1080/01691864.2019.1702897

- [33] M. Fujita, Y. Domae, A. Noda, G. A. G. Ricardez, T. Nagatani, A. Zeng, S. Song, A. Rodriguez, A. Causo, I. M. Chen, and T. Ogasawara, “What are the important technologies for bin picking? Technology analysis of robots in competitions based on a set of performance metrics,” Advanced Robotics, Vol.34, Issues 7-8, pp. 560-574, 2020. https://doi.org/10.1080/01691864.2019.1698463

- [34] N. Sidki, “Autonomous pick and place for mechanical assembly WRS 2020 assembly challenge,” J. Robot. Mechatron., Vol.35, No.1, pp. 43-50, 2023. https://doi.org/10.20965/jrm.2023.p0043

- [35] C. Sloth, A. Kramberger, and I. Iturrate, “Towards easy setup of robotic assembly tasks,” Advanced Robotics, Vol.34, Issues 7-8, pp. 499-513, 2020. https://doi.org/10.1080/01691864.2019.1704869

- [36] C. Schlette, A. G. Buch, F. Hagelskjær, I. Iturrate, D. Kraft, A. Kramberger, A. P. Lindvig, S. Mathiesen, H. G. Petersen, M. H. Rasmussen, T. R. Savarimuthu, C. Sloth, L. C. Sørensen, and T. N. Thulesen, “Towards robot cell matrices for agile production—SDU robotics’ assembly cell at the WRC 2018,” Advanced Robotics, Vol.34, Issues 7-8, pp. 422-438, 2020. https://doi.org/10.1080/01691864.2019.1686422

- [37] L. Xu, F. N. Heravi, M. G. Lahoud, G. Marchello, M. D’Imperio, S. H. J. Abidi, M. Farajtabar, M. Martini, S. Cocuzza, M. Scaccia, and F. Cannella, “Development of a flexible assembly system for the world robot summit 2020 assembly challenge,” J. Robot. Mechatron., Vol.35, No.1, pp. 51-64, 2023. https://doi.org/10.20965/jrm.2023.p0051

- [38] K. Harada and M. Kaneko, “Kinematics and internal force in grasping multiple objects,” Proc. of IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, Vol.1, pp. 298-303, 1998. https://doi.org/10.1109/IROS.1998.724635

- [39] T. Yoshikawa, T. Watanabe, and M. Daito, “Optimization of power grasps for multiple objects,” Proc. of IEEE Int. Conf. on Robotics and Automation, Vol.2, pp. 1786-1791, 2001. https://doi.org/10.1109/ROBOT.2001.932868

- [40] A. Shenoy, T. Chen, and Y. Sun, “Multi-object grasping—Efficient robotic picking and transferring policy for batch picking,” 2022 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 2741-2747, 2022. https://doi.org/10.1109/IROS47612.2022.9981799

- [41] Y. Li, B. Liu, Y. Geng, P. Li, Y. Yang, Y. Zhu, T. Liu, and S. Huang, “Grasp multiple objects with one hand,” IEEE Robotics and Automation Letters, Vol.9, Issue 5, pp. 4027-4034, 2024. https://doi.org/10.1109/LRA.2024.3374190

- [42] W. C. Agboh, K. Ichnowski, J. Goldberg, and M. R. Dogar, “Multi-object grasping in the plane,” A. Billard, T. Asfour, and O. Khatib (Eds.), “Robotics Research,” pp. 222-238, Springer, 2023. https://doi.org/10.1007/978-3-031-25555-7_15

- [43] T. Yamada and H. Yamamoto, “Static grasp stability analysis of multiple spatial objects,” J. of Control Science and Engineering, Vol.3, pp. 118-139, 2015. https://doi.org/10.17265/2328-2231/2015.03.002

- [44] S. Makita and K. Makihara, “Homogeneous quantitative measure of caging grasps with both geometrical and mechanical constraints,” Int. Conf. on Control, Automation and Systems, pp. 311-316, 2019. https://doi.org/10.23919/ICCAS47443.2019.8971548

- [45] T. Omata and K. Nagata, “Rigid body analysis of the indeterminate grasp force in power grasps,” IEEE Trans. on Robotics and Automation, Vol.16, Issue 1, pp. 46-54, 2000. https://doi.org/10.1109/70.833187

- [46] J. Su, H. Qiao, C. Liu, Y. Song, and A. Yang, “Grasping objects: The relationship between the cage and the form-closure grasp,” IEEE Robotics and Automation Magazine, Vol.24, Issue 3, pp. 84-96, 2017. https://doi.org/10.1109/MRA.2016.2615332

- [47] T. Makapunyo, T. Phoka, P. Pipattanasomporn, N. Niparnan, and A. Sudsang, “Measurement framework of partial cage quality based on probabilistic motion planning,” Proc. of IEEE Int. Conf. on Robotics and Automation, pp. 1574-1579, 2013. https://doi.org/10.1109/ICRA.2013.6630780

- [48] M. C. Welle, A. Varava, J. Mahler, K. Goldberg, D. Kragic, and F. T. Pokorny, “Partial caging: A clearance-based definition, datasets, and deep learning,” Autonomous Robots, Vol.45, pp. 647-664, 2021. https://doi.org/10.1007/s10514-021-09969-6

- [49] Y. Jiang, C. Zheng, M. Lim, and A. Saxena, “Learning to place new objects,” Proc. of IEEE Int. Conf. on Robotics and Automation, pp. 3088-3095, 2012. https://doi.org/10.1109/ICRA.2012.6224581

- [50] J. Mahler, F. T. Pokorny, Z. Mccarthy, A. F. van der Stappen, and K. Goldberg, “Energy-bounded caging: Formal definition and 2-D energy lower bound algorithm based on weighted alpha shapes,” IEEE Robotics and Automation Letters, Vol.1, Issue 1, pp. 508-515, 2016. https://doi.org/10.1109/LRA.2016.2519145

- [51] A. Shirizly, E. D. Rimon, and W. Wan, “Contact space computation of two-finger gravity based caging grasps security measure,” IEEE Robotics and Automation Letters, Vol.6, Issue 2, pp. 572-579, 2020. https://doi.org/10.1109/LRA.2020.3047773

- [52] A. Bicchi, “On the closure properties of robotic grasping,” Int. J. of Robotics Research, Vol.14, Issue 4, pp. 319-334, 1995. https://doi.org/10.1177/027836499501400402

- [53] E. Rimon and J. Burdick, “The Mechanics of Robot Grasping,” Cambridge University Press, 2019. https://doi.org/10.1017/9781108552011

- [54] Q.-Y. Zhou, J. Park, and V. Koltun, “Open3D: A modern library for 3D data processing,” arXiv:1801.09847, 2018. https://doi.org/10.48550/arXiv.1801.09847

- [55] G. Bradski, “The OpenCV Library,” Dr. Dobb’s J. of Software Tools, Vol.25, No.11, pp. 120,122-125, 2000.

- [56] Z. Wang and V. Kumar, “Object closure and manipulation by multiple cooperating mobile robots,” Proc. of IEEE Int. Conf. on Robotics and Automation, pp. 394-399, 2002. https://doi.org/10.1109/ROBOT.2002.1013392

- [57] N. Otsu, “A threshold selection method from gray-level histograms,” IEEE Trans. on Systems, Man, and Cybernetics, Vol.9, Issue 1, pp. 62-66, 1979. https://doi.org/10.1109/TSMC.1979.4310076

- [58] A. Komadina, M. Martinić, S. Groš, and Z. Mihajlović, “Comparing threshold selection methods for network anomaly detection,” IEEE Access, Vol.12, pp. 124943-124973, 2024. https://doi.org/10.1109/ACCESS.2024.3452168

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.