Paper:

Construction of a Mixing State Estimation System in a Peristaltic Mixing Conveyor that Imitates Intestine —Proposal of an Estimation Method to Improve Generalizability for Mixture’s Input Conditions—

Takaaki Tanno*

, Iori Terayama*

, Iori Terayama*

, Ryosuke Adachi*, Rie Nishihama**, and Taro Nakamura*

, Ryosuke Adachi*, Rie Nishihama**, and Taro Nakamura*

*Department of Precision Mechanics, Faculty of Science and Engineering, Chuo University

1-13-27 Kasuga, Bunkyo-ku, Tokyo 112-8551, Japan

**Research and Development Initiative, Chuo University

1-13-27 Kasuga, Bunkyo-ku, Tokyo 112-8551, Japan

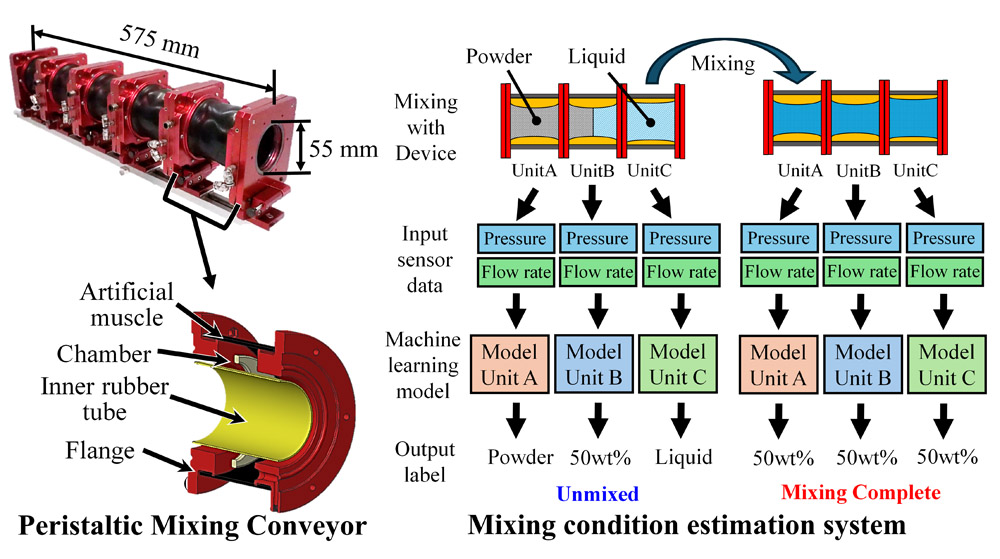

A peristaltic mixing and conveyor that imitates the intestines of living organisms is used to mix powders and highly viscous fluids at low shear force in the manufacturing processes of foods, pharmaceuticals, paints, cosmetics, and other products. Although the device uses sequence control to mix and convey the contents, the actual intestine controls its motion autonomously according to the state of the contents. This research aims to establish an autonomous control method that can change between mixing and conveying according to the state of the mixture. In this paper, we propose a method to construct a learning model that is not affected by the content input conditions, in which samples with different total input amounts and mixing ratios are fed into the device, and sensor values acquired during the device operation are used as training data. The generalizability of the learning model was verified, and it was shown that mixing state estimation was possible up to 20 min from the start of mixing for mixtures with different input amounts and input order.

Peristaltic mixing conveyor and mixing state estimation

- [1] S. Anwar and X. Li, “A review of high-quality epoxy resins for corrosion-resistant applications,” J. of Coatings Technology and Research, Vol.21, pp. 461-480, 2024. https://doi.org/10.1007/s11998-023-00865-5

- [2] P. S. Chow et al., “Influence of manufacturing process on the microstructure, stability, and sensorial properties of a topical ointment formulation,” Pharmaceutics, Vol.15, Issue 9, Article No.2219, 2023. https://doi.org/10.3390/pharmaceutics15092219

- [3] R. Kumar et al., “Mixing technologies in the pharmaceutical industries,” J. of Emerging Technologies and Innovative Research (JETIR), Vol.5, Issue 11, pp. 606-609, 2018.

- [4] H. M. Cheng, K. K. Mah, and K. Seluakumaran, “Defining physiology: Principles, themes, concepts. volume 2,” Springer, Berlin, Germany, pp. 35-37, 2020. https://doi.org/10.1007/978-3-030-62285-5

- [5] A. M. Holland et al., “The enteric nervous system in gastrointestinal disease etiology,” Cellular and Molecular Life Sciences, Vol.78, pp. 4713-4733, 2021. https://doi.org/10.1007/s00018-021-03812-y

- [6] K. Suzuki and T. Nakamura, “Development of a peristaltic pump based on bowel peristalsis using for artificial rubber muscle,” Proc. of 2010 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS2010), pp. 3085-3090, 2010. https://doi.org/10.1109/IROS.2010.5653006

- [7] S. Yoshihama et al., “Powder conveyance experiments with peristaltic conveyor using a pneumatic artificial muscle,” Proc. of 2016 IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics (AIM2016), 2016. https://doi.org/10.1109/AIM.2016.7576989

- [8] S. Yoshihama, R. Ban, T. Nakamura, A. Iwasaki, and H. Habu, “Mixing of solid propellant by peristaltic pump based on bowel peristalsis,” Proc. of IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS2015), pp. 3862-3868, 2015. https://doi.org/10.1109/IROS.2015.7353920

- [9] K. Ashigaki, A. Iwasaki, D. Hagiwara, K. Negishi, K. Matsumoto, Y. Yamada, H. Habu, and T. Nakamura, “Considering mixing process of rocket solid propellant using mixing transport device simulating peristaltic movement of intestinal tract,” Proc. of 7th IEEE Int. Conf. on Biomedical Robotics and Biomechatronics (BioRob), pp. 1291-1296, 2018. https://doi.org/10.1109/BIOROB.2018.8487789

- [10] K. Wakamatsu et al., “Content detection for continuous and efficient production of solid rocket fuel by peristaltic mixer,” Proc. of 2020 IEEE/SICE Int. Symp. on System Integration (SII), pp. 471-476, 2020. https://doi.org/10.1109/SII46433.2020.9025893

- [11] K. Wakamatsu et al., “Mixing state estimation of peristaltic continuous mixing conveyor with distributed sensing system based on soft intestine motion,” Proc. of 2020 3rd IEEE Int. Conf. on Soft Robotics (RoboSoft), 2020. https://doi.org/10.1109/RoboSoft48309.2020.9116058

- [12] S. Oshino et al., “Generalization capability of mixture estimation model for peristaltic continuous mixing conveyor,” IEEE Access, Vol.9, pp. 138866-138875, 2021. https://doi.org/10.1109/ACCESS.2021.3112614

- [13] S. Oshino et al., “Mixing determination for solid rocket fuel production by peristaltic mixing pump using packing method,” Proc. of 48th Annual Conf. of the IEEE Industrial Electronics Society (IECON2022), 2022. https://doi.org/10.1109/IECON49645.2022.9968625

- [14] I. Terayama, S. Oshino, R. Nishihama, M. Okui, R. Adachi, and T. Nakamura, “Construction of motion mode switching system by machine learning for peristaltic mixing conveyor based on intestinal movement,” IEEE Access, Vol.12, pp. 25980-25992, 2024. https://doi.org/10.1109/ACCESS.2024.3366457

- [15] I. Terayama, S. Oshino, R. Nishihama, M. Okui, and T. Nakamura, “Discrimination of powder particle size and input amounts for the estimation of mixing using a peristaltic mixing conveyor imitating an intestinal tube,” Proc. of 2023 IEEE/SICE Int. Symp. on System Integration (SII), 2023. https://doi.org/10.1109/SII55687.2023.10039173

- [16] F. Esser, T. Masselter, and T. Speck, “Silent pumpers: A comparative topical overview of the peristaltic pumping principle in living nature, engineering, and biomimetics,” Advanced Intelligent Systems, Vol.1, No.2, Article No.1900009, 2019. https://doi.org/10.1002/aisy.201900009

- [17] J. Klespitz and L. Kovács, “Peristaltic pumps – A review on working and control possibilities,” Proc. of 2014 IEEE 12th Int. Symp. on Applied Machine Intelligence and Informatics (SAMI), pp. 191-194, 2014. https://doi.org/10.1109/SAMI.2014.6822404

- [18] S. Dirven, W. Xu, and L. K. Cheng, “Sinusoidal peristaltic waves in soft actuator for mimicry of esophageal swallowing,” IEEE/ASME Trans. on Mechatronics, Vol.20, No.3, pp. 1331-1337, 2015. https://doi.org/10.1109/TMECH.2014.2337291

- [19] S. Din, W. Xu, L. K. Cheng, and S. Dirven, “A stretchable array of electronic receptors for esophageal swallowing robot for biomimetic simulations of bolus transport,” IEEE Sensors J., Vol.18, No.13, pp. 5497-5506, 2018. https://doi.org/10.1109/JSEN.2018.2836330

- [20] L. Costi, J. Hughes, J. Biggins, and F. Iida, “Bioinspired soft bendable peristaltic pump exploiting ballooning for high volume throughput,” IEEE Trans. on Medical Robotics and Bionics, Vol.4, No.3, pp. 570-577, 2022. https://doi.org/10.1109/TMRB.2022.3192763

- [21] J. Muška, P. Karban, I. Petrášová, and I. Doležel, “Design of linear peristaltic pump,” Proc. of 2019 IEEE 20th Int. Conf. on Computational Problems of Electrical Engineering (CPEE), 2019. https://doi.org/10.1109/CPEE47179.2019.8949082

- [22] M. Watanabe, K. Tadakuma, M. Konyo, and S. Tadokoro, “Bundled rotary helix drive mechanism capable of smooth peristaltic movement,” IEEE Robotics and Automation Letters, Vol.5, No.4, pp. 5537-5544, 2020. https://doi.org/10.1109/LRA.2020.2986993

- [23] S. Dirven, P. Xu, L. Cheng, and J. Bronlund, “Soft-robotic peristaltic pumping inspired by esophageal swallowing in man,” J. H. Kim, E. Matson, H. Myung, P. Xu, and F. Karray (Eds.), “Robot Intelligence Technology and Applications 2,” Advances in Intelligent Systems and Computing, Vol.274, pp. 473-482, 2014. https://doi.org/10.1007/978-3-319-05582-4_41

- [24] F. Tauber, F. Krüger, T. Masselter, and T. Speck, “Development and characterization of a novel biomimetic peristaltic pumping system with flexible silicone-based soft robotic ring actuators,” V. Vouloutsi et al. (Eds.), “Biomimetic and Biohybrid Systems,” pp. 157-167, Springer, 2018. https://doi.org/10.1007/978-3-319-95972-6_17

- [25] T. Abe, S. Oh-hara, and Y. Ukita, “Adoption of reinforcement learning for the intelligent control of a microfluidic peristaltic pump,” Biomicrofluidics, Vol.15, Issue 3, Article No.034101, 2021. https://doi.org/10.1063/5.0032377

- [26] D. Vorlander, G. Schultz, K. Hoffmann, D. Rasch, and K. Dohnt, “PETR: A novel peristaltic mixed tubular bioreactor simulating human colonic conditions,” Biotechnology and Bioengineering, Vol.121, Issue 3, pp. 1118-1143, 2024. https://doi.org/10.1002/bit.28636

- [27] X. Cui, Y. Huang, Z. Hu, P. Wu, and X. D. Chen, “Design, construction and solid-liquid separation performance of a human colon inspired soft-elastic reactor (CSER): Breakage, emptying, and solid-liquid separation of the agar gel particles,” Chemical Engineering and Processing – Process Intensification, Vol.199, Article No.109763, 2024. https://doi.org/10.1016/j.cep.2024.109763

- [28] T. Tanno, I. Terayama, R. Adachi, R. Nishihama, and T. Nakamura, “Construction of a system for detecting the degree of mixing in peristaltic mixing conveyor for continuous manufacturing of solid rocket propellant—Construction of a machine learning model focused on initial placement of materials and verification of discrimination accuracy—,” Proc. of Int. Symp. on Artificial Intelligence, Robotics and Automation in Space (i-SAIRAS 2024), 2024.

- [29] S. Hochreiter and J. Schmidhuber, “Long short-term memory,” Neural Computation, Vol.9, Issue 8, pp. 1735-1780, 1997. https://doi.org/10.1162/neco.1997.9.8.1735

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.