Paper:

Model Validation Using Ready-Made Components Toward Flexible Hydraulic Joints

Ryo Arai and Satoru Sakai

Shinshu University

4-17-1 Wakasato, Nagano, Nagano 380-8553, Japan

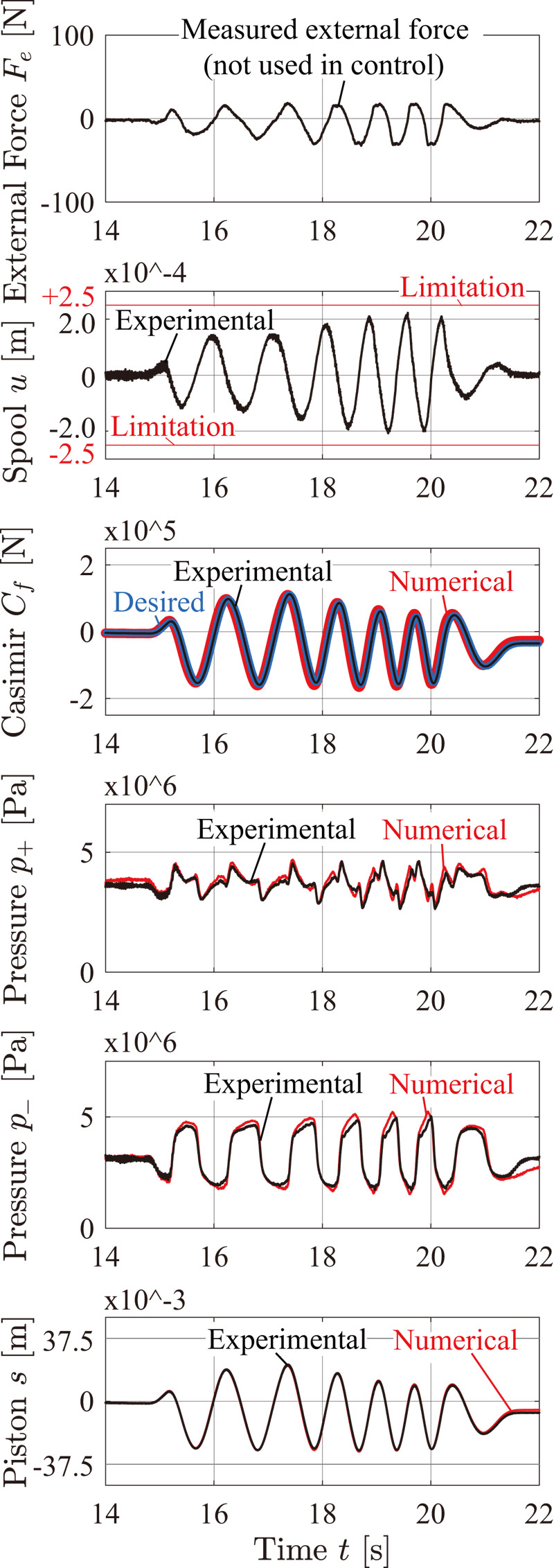

This paper discusses model validation of hydraulic joints in the presence of unknown external forces using ready-made components. First, we review hydraulic cylinder dynamics with nonlinear pressure dynamics. Second, we design a controller that applies existing methods so that hydraulic joints have high backdrivability against unknown external forces. Third, we discuss the experimental and numerical responses of hydraulic joints in the presence of unknown external forces as the model validation. No custom-made cylinders, valves, or pipes are used in our experiments. Remarkably, the experimental and numerical responses were close to each other in the presence of unknown external forces.

Model validation with non short pipe (1.9 m)

- [1] P. A. Lasota, T. Fong, and J. A. Shah, “A survey of methods for safe human-robot interaction,” Foundations and Trends® in Robotics, Vol.5, No.4, pp. 261-349, 2017. https://doi.org/10.1561/2300000052

- [2] J. Mattila, J. Koivumäki, D. G. Caldwell, and C. Semini, “A survey on control of hydraulic robotic manipulators with projection to future trends,” IEEE/ASME Trans. on Mechatronics, Vol.22, No.2, pp. 669-680, 2017. https://doi.org/10.1109/TMECH.2017.2668604

- [3] S. Sakai and Y. Maeshima, “A new method for parameter identification for N-DOF hydraulic robots,” 2014 IEEE Int. Conf. on Robotics and Automation, pp. 5983-5989, 2014. https://doi.org/10.1109/ICRA.2014.6907741

- [4] R. Arai, S. Sakai, A. Tatsuoka, and Q. Zhang, “Analytical, experimental, and numerical investigation of energy in hydraulic cylinder dynamics of agriculture scale excavators,” Energies, Vol.14, No.19, Article No.6210, 2021. https://doi.org/10.3390/en14196210

- [5] A. Saleem and M.-H. Kim, “CFD analysis on the air-side thermal-hydraulic performance of multi-louvered fin heat exchangers at low Reynolds numbers,” Energies, Vol.10, No.6, Article No.823, 2017. https://doi.org/10.3390/en10060823

- [6] R. Arai, S. Sakai, and K. Ono, “Response improvement of hydraulic robotic joints via a force servo and inverted pendulum demo,” IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 761-766, 2024. https://doi.org/10.1109/IROS58592.2024.10802664

- [7] Y. Shioi and S. Sakai, “Casimir based gravity compensations for hydraulic arms,” 56th Annual Conf. of the Society of Instrument and Control Engineers of Japan, pp. 22-24, 2017. https://doi.org/10.23919/SICE.2017.8105561

- [8] G. Aguirre Dominguez, M. Kamezaki, and S. Sugano, “Proposal and preliminary feasibility study of a novel toroidal magnetorheological piston,” IEEE/ASME Trans. on Mechatronics, Vol.22, No.2, pp. 657-668, 2017. https://doi.org/10.1109/TMECH.2016.2622287

- [9] H. Kaminaga, J. Ono, Y. Nakashima, and Y. Nakamura, “Development of backdrivable hydraulic joint mechanism for knee joint of humanoid robots,” 2009 IEEE Int. Conf. on Robotics and Automation, pp. 1577-1582, 2009. https://doi.org/10.1109/ROBOT.2009.5152866

- [10] S. Sakai and S. Stramigioli, “Visualization of hydraulic cylinder dynamics by a structure preserving nondimensionalization,” IEEE/ASME Trans. on Mechatoronics, Vol.23, No.5, pp. 2196-2206, 2018. https://doi.org/10.1109/TMECH.2018.2854751

- [11] S. Sakai, M. Obara, and K. Chikazawa, “Parameter identification via nominal integrator of hydraulic cylinder dynamics,” IFAC-PapersOnLine, Vol.54, No.14, pp. 78-83, 2021. https://doi.org/10.1016/j.ifacol.2021.10.332

- [12] A. J. van der Schaft and B. M. J. Maschke, “The Hamiltonian formulation of energy conserving physical systems with external ports,” Archiv für Elektronik und Übertragungstechnik, Vol.49, Nos.5/6, pp. 362-371, 1995.

- [13] A. van der Schaft, “L2-Gain and Passivity Techniques in Nonlinear Control,” Springer, 2017.

- [14] A. Kugi and W. Kemmetmüller, “New energy-based nonlinear controller for hydraulic piston actuators,” European J. of Control, Vol.10, No.2, pp. 163-173, 2004. https://doi.org/10.3166/ejc.10.163-173

- [15] S. Sakai, “Fast computation by simplifications of a class of hydro-mechanical systems,” IFAC Proc. Volumes, Vol.45, No.19, pp. 7-12, 2012. https://doi.org/10.3182/20120829-3-IT-4022.00006

- [16] S. Sakai, “Further results on the fast computation of a class of hydro-mechanical systems,” IFAC-PapersOnLine, Vol.51, No.3, pp. 74-79, 2018. https://doi.org/10.1016/j.ifacol.2018.06.018

- [17] S. Sakai, M. Iida, K. Osuka, and M. Umeda, “Design and control of a heavy material handling manipulator for agricultural robots,” Autonomous Robots, Vol.25, No.3, pp. 189-204, 2008. https://doi.org/10.1007/s10514-008-9090-y

- [18] A. Ryo, “Analysis and validation of a force servo toward hydraulic collaborative robots in agriculture,” Doctoral dissertation (under review), 2024.

- [19] L. Ljung, “System Identification: Theory for the User,” 2nd Ed., Prentice Hall, 1999.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.