Paper:

Adaptive Origami Electrostatic Adhesion Technology for Curved Objects

Shuta Okamoto

, Yusuke Akitsu, and Hiroki Shigemune

, Yusuke Akitsu, and Hiroki Shigemune

Active Functional Devices Laboratory, Shibaura Institute of Technology

3-7-5 Toyosu, Koto-ku, Tokyo 135-8548, Japan

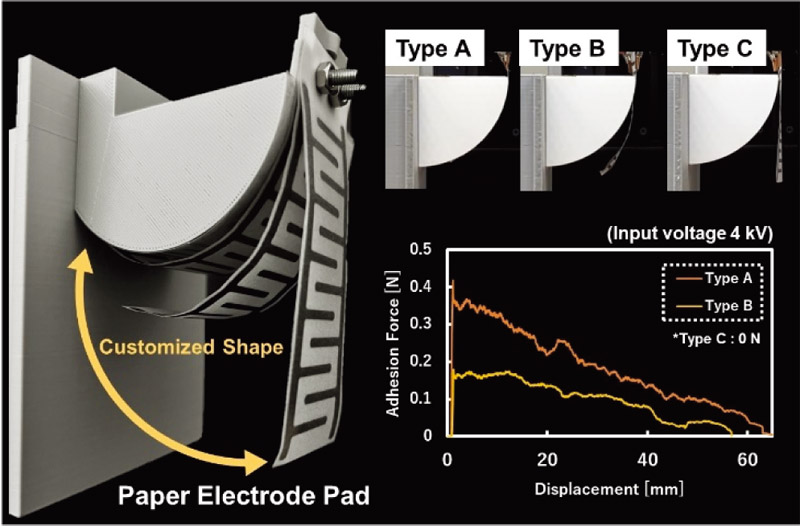

Soft robots have promising applications in healthcare, manufacturing, and disaster relief. Inspired by biological models, their superior flexibility and environmental adaptability have increased their use in soft grippers. However, soft grippers often struggle with precise force control and high energy consumption during operation. One solution to these challenges is the utilization of electrostatic adhesion technology. This technology uses electrostatic forces generated by applying a high voltage between electrodes to adhere to objects, allowing for energy-efficient and delicate manipulation. We propose a novel paper-based origami electroadhesive pad (p-OEP) utilizing paper mechatronics. Thin-film comb electrodes were formed through inkjet printing, and self-folding technology was employed to create a structure that adapts to the curvature of the target object. This increases the adhesive area between the p-OEP and object, achieving high strength. This innovative approach expands the application range of soft grippers and provides a new gripping solution that is low-cost and environmentally friendly.

Paper-based origami electroadhesive pad (p-OEP)

- [1] N. El-Atab, R. B. Mishra, F. Al-Modaf, L. Joharji, A. A. Alsharif, H. Alamoudi, M. Diaz, N. Qaiser, and M. M. Hussain, “Soft actuators for soft robotic applications: a review,” Advanced Intelligent Systems, Vol.2, No.10, Article No.2000128, 2020. https://doi.org/10.1002/aisy.202000128

- [2] K. Yokouchi, T. Kamegawa, T. Matsuno, T. Hiraki, T. Yamaguchi, and A. Gofuku, “Development of a gripper with variable stiffness for a CT-guided needle insertion robot,” J. Robot. Mechatron., Vol.32, No.3, pp. 692-700, 2020. https://doi.org/10.20965/jrm.2020.p0692

- [3] D. Rus and M. T. Tolley, “Design, fabrication and control of soft robots,” Nature, Vol.521, No.7553, pp. 467-475, 2015. https://doi.org/10.1038/nature14543

- [4] C. Jianfei and W. Xingsong, “Conception of a tendon-sheath and pneumatic system driven soft rescue robot,” J. H. Kim, W. Yang, J. Jo, P. Sincak, and H. Myung (Eds.), “Robot Intelligence Technology and Applications 3. Advances in Intelligent Systems and Computing,” Springer, pp. 475-481, 2015. https://doi.org/10.1007/978-3-319-16841-8_43

- [5] G. Giordano, M. Carlotti, and B. Mazzolai, “A perspective on cephalopods mimicry and bioinspired technologies toward proprioceptive autonomous soft robots,” Advanced Materials Technologies, Vol.6, No.12, Article No.2100437, 2021. https://doi.org/10.1002/admt.202100437

- [6] P. Polygerinos, Z. Wang, K. C. Galloway, R. J. Wood, and C. J. Walsh, “Soft robotic glove for combined assistance and at-home rehabilitation,” Robotics and Autonomous Systems, Vol.73, pp. 135-143, 2015. https://doi.org/10.1016/j.robot.2014.08.014

- [7] G. Endo, K. Yamagishi, Y. Yamanaka, and K. Tadakuma, “Development of High-Durability Flexible Fabrics Using High-Strength Synthetic Fibers and its Application to Soft Robots,” J. Robot. Mechatron., Vol.34, No.2, pp. 266-269, 2022. https://doi.org/10.20965/jrm.2022.p0266

- [8] J. Shintake, V. Cacucciolo, D. Floreano, and H. Shea, “Soft robotic grippers,” Advanced Materials, Vol.30, No.29, Article No.1707035, 2018. https://doi.org/10.1002/adma.201707035

- [9] J. F. Elfferich, D. Dodou, and C. D. Santina, “Soft robotic grippers for crop handling or harvesting: A review,” IEEE Access, Vol.10, pp. 75428-75443, 2022. https://doi.org/10.1109/ACCESS.2022.3190863

- [10] Z. Wang, Y. Makiyama, and S. Hirai, “A soft needle gripper capable of grasping and piercing for handling food materials,” J. Robot. Mechatron., Vol.33, No.4, pp. 935-943, 2021. https://doi.org/10.20965/jrm.2021.p0935

- [11] J. Guo, J. Leng, and J. Rossiter, “Electroadhesion technologies for robotics: A comprehensive review,” IEEE Trans. on Robotics, Vol.36, No.2, pp. 313-327, 2020. https://doi.org/10.1109/TRO.2019.2956869

- [12] P. Rajagopalan, M. Muthu, Y. Liu, J. Luo, X. Wang, and C. Wan, “Advancement of Electroadhesion Technology for Intelligent and Self-Reliant Robotic Applications,” Advanced Intelligent Systems, Vol.4, No.7, Article No.2200064, 2022. https://doi.org/10.1002/aisy.202200064

- [13] J. Shintake, S. Rosset, B. Schubert, D. Floreano, and H. Shea, “Versatile soft grippers with intrinsic electroadhesion based on multifunctional polymer actuators,” Advanced Materials, Vol.28, No.2, pp. 231-238, 2016. https://doi.org/10.1002/adma.201504264

- [14] K. Choi, Y. C. Kim, H. Sun, S.-H. Kim, J. W. Yoo, I.-K. Park, P.-C. Lee, H. J. Choi, H. R. Choi, T. Kim, J. Suhr, Y. K. Lee, and J.-D. Nam, “Quantitative electrode design modeling of an electrostatic lifting device based on the localized charge distribution and interfacial polarization of different objects,” ACS Omega, Vol.4, No.5, pp. 7994-8000, 2019. https://doi.org/10.1021/acsomega.9b00071

- [15] E. W. Schaler, D. Ruffatto, P. Glick, V. White, and A. Parness, “An electrostatic gripper for flexible objects,” 2017 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 1172-1179, 2017. https://doi.org/10.1109/IROS.2017.8202289

- [16] Y. Okuno, H. Shigemune, Y. Kuwajima, and S. Maeda, “Stretchable suction cup with electroadhesion,” Advanced Materials Technologies, Vol.4, No.1, Article No.1800304, 2019. https://doi.org/10.1002/admt.201800304

- [17] H. Wang and A. Yamamoto, “Analyses and solutions for the buckling of thin and flexible electrostatic inchworm climbing robots,” IEEE Trans. on Robotics, Vol.33, No.4, pp. 889-900, 2017. https://doi.org/10.1109/TRO.2017.2690302

- [18] Q. Hu, J. Li, E. Dong, and D. Sun, “Soft scalable crawling robots enabled by programmable origami and electrostatic adhesion,” IEEE Robotics and Automation Letters, Vol.8, No.4, pp. 2365-2372, 2023. https://doi.org/10.1109/LRA.2023.3251181

- [19] M. A. Graule, P. Chirarattananon, S. B. Fuller, N. T. Jafferis, K. Y. Ma, M. Spenko, R. Kornbluh, and R. J. Wood, “Perching and takeoff of a robotic insect on overhangs using switchable electrostatic adhesion,” Science, Vol.352, No.6288, pp. 978-982, 2016. https://doi.org/10.1126/science.aaf1092

- [20] J. Guo, C. Xiang, A. Conn, and J. Rossiter, “All-soft skin-like structures for robotic locomotion and transportation,” Soft Robotics, Vol.7, No.3, pp. 309-320, 2020. https://doi.org/10.1089/soro.2019.0059

- [21] H. Shigemune, S. Maeda, V. Cacucciolo, Y. Iwata, E. Iwase, S. Hashimoto, and S. Sugano, “Printed paper robot driven by electrostatic actuator,” IEEE Robotics and Automation Letters, Vol.2, No.2, pp. 1001-1007, 2017. https://doi.org/10.1109/LRA.2017.2658942

- [22] M. Mastrangelo, F. Caruso, G. Carbone, and V. Cacucciolo, “Electroadhesion zipping with soft grippers on curved objects,” Extreme Mechanics Letters, Vol.61, Article No.101999, 2023. https://doi.org/10.1016/j.eml.2023.101999

- [23] D. Naritomi, N. Waragai, H. Minamide, S. Ueno, and H. Shigemune, “Paper cushioning structure with an embedded printed sensor,” 2022 IEEE 11th Global Conf. on Consumer Electronics (GCCE), pp. 243-244, 2022. https://doi.org/10.1109/GCCE56475.2022.10014344

- [24] H. Shigemune, S. Maeda, Y. Hara, N. Hosoya, and S. Hashimoto, “Origami robot: A self-folding paper robot with an electrothermal actuator created by printing,” IEEE/ASME Trans. on Mechatronics, Vol.21, No.6, pp. 2746-2754, 2016. https://doi.org/10.1109/TMECH.2016.2593912

- [25] D. Naritomi, N. Hosoya, G. Ando, S. Maeda, and H. Shigemune, “Creation of origami-inspired honeycomb structure using self-folding paper,” Materials & Design, Vol.223, Article No.111146, 2022. https://doi.org/10.1016/j.matdes.2022.111146

- [26] Y. Fukatsu and H. Shigemune, “Development of self-folded corrugated structures using automatic origami technique by inkjet printing,” Advanced Intelligent Systems, Vol.4, No.6, Article No.2100260, 2022. https://doi.org/10.1002/aisy.202100260

- [27] A. Minaminosono, R. Toyoda, N. Hosoya, and S. Maeda, “Fabrication of a stretchable electrostatic pad,” 2022 Int. Symp. on Micro-NanoMehatronics and Human Science (MHS), 2022. https://doi.org/10.1109/MHS56725.2022.10092034

- [28] S. Schaller and H. Shea, “Measuring electro-adhesion pressure before and after contact,” Scientific Reports, Vol.13, No.1, Article No.11768, 2023. https://doi.org/10.1038/s41598-023-38872-6

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.