Paper:

Propulsion Method of Modular Robot Using Different Types of Locomotion Modules

Sakuya Ono

and Yoshihisa Uchida

and Yoshihisa Uchida

Department of Mechanical Engineering, Faculty of Engineering, Aichi Institute of Technology

1247 Yachigusa, Yakusa-cho, Toyota, Aichi 470-0392, Japan

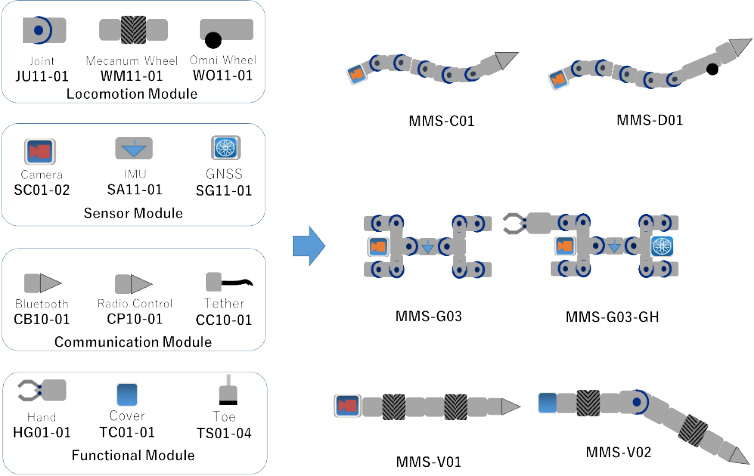

Multi-purpose module system (MMS), which is one of the module robots, consists of locomotion, sensor, communication, and function modules. The MMS can be transformed into a series-connected form or a quadruped form, following which appropriate sensors can be added. Therefore, the MMS can be used as a rescue robot in an unknown situation. This study presents an overview of each of the modules that comprise the developed MMS, as well as an overview of each of the forms in which they are combined. Considering that the MMS feature can freely combine different types of modules, we developed MMS-D01, which combined serpentine and wheeled propulsion, and MMS-V02, which combined Mecanum-wheeled propulsion and stable traveling using joint control. These developed MMSs were evaluated under various conditions.

Schematic of the MMS

- [1] Y. Li, S. Ge, H. Zhu, H. Fang, and J. Gao, “Mobile platform of rocker-type coal mine rescue robot,” Mining Science and Technology, Vol.20, No.3, pp. 466-471, 2010. https://doi.org/10.1016/S1674-5264(09)60227-1

- [2] R. Miura et al., “Development of a decommissioning robot with a simple structure capable of traversing steps using two different drive systems,” J. Robot. Mechatron., Vol.36, No.1, pp. 95-106, 2024. https://doi.org/10.20965/jrm.2024.p0095

- [3] H. Miura, A. Watanabe, M. Okugawa, and T. Miura, “Verification and evaluation of robotic inspection of the inside of culvert pipes,” J.Robot. Mechatron., Vol.31, No.6, pp. 794-802, 2019. https://doi.org/10.20965/jrm.2019.p0794

- [4] S. Leggieri, C. Canali, and D. G. Caldwell, “Design, modeling, and experimental analysis of the crawler unit for inspection in constrained space,” Annual Reviews in Control, Vol.57, Article No.100950, 2024. https://doi.org/10.1016/j.arcontrol.2024.100950

- [5] M. Li, Z. Jiang, P. Wang, L. Sun, and S. S. Ge, “Control of a quadruped robot with bionic springy legs in trotting gait,” J. of Bionic Engineering, Vol.11, No.2, pp. 188-198, 2014. https://doi.org/10.1016/S1672-6529(14)60043-3

- [6] E. V. Kumar and J. Jerome, “Robust LQR controller design for stabilizing and trajectory tracking of inverted pendulum,” Procedia Engineering, Vol.64, pp. 169-178, 2013. https://doi.org/10.1016/j.proeng.2013.09.088

- [7] J.-J. Wang, D.-L. Liu, and B.-J. Wang, “Research on one type of saturated nonlinear stabilization control method of X-Z inverted pendulum,” Acta Automatica Sinica, Vol.39, No.1, pp. 92-96, 2013. https://doi.org/10.1016/S1874-1029(13)60011-7

- [8] C. Prados, M. Hernando, E. Gambao, and A. Brunete, “Torque-based control of a bio-inspired modular climbing robot,” Machines, Vol.11, No.7, Article No.757, 2023. https://doi.org/10.3390/machines11070757

- [9] M. Nakajima, Q. Cheng, and M, Tanaka, “Gait design and experimental validation of a snake robot on a pipe with branches using spiral stairs function,” Artificial Life and Robotics, Vol.27, No.2, pp. 300-307, 2022. https://doi.org/10.1007/s10015-022-00752-z

- [10] K. Harada, R. Ariizumi, M. Tanaka, T, Asai, and S. Azuma, “Head trajectory tracking control of an extendable snake-like robot,” Artificial Life and Robotics, Vol.27, No.2, pp. 316-323, 2022. https://doi.org/10.1007/s10015-022-00750-1

- [11] Y. Iguchi, M. Nakajima, R. Ariizumi, and M. Tanaka, “Step climbing control of snake robot with prismatic joints,” Sensors, Vol.22, No.13, Article No.4920, 2022. https://doi.org/10.3390/s22134920

- [12] B. Seyidoğlu and A. Rafsanjani, “A textile origami snake robot for rectilinear locomotion,” Device, Vol.2, No.2, Article No.100226, 2024. https://doi.org/10.1016/j.device.2023.100226

- [13] A. C. A. Dione and S. Hasegawa, “Stable posture tracking for modular spatial hyper-redundant serial arms using selective control points,” Advanced Robotics, Vol.38, No.1, pp. 14-28. 2023. https://doi.org/10.1080/01691864.2023.2291715

- [14] R. Ariizumi, K. Sakakibara, T. Asai, and S. Azuma, “Path-following control of a snake robot with multiple passive joints,” Int. J. of Control, Automation and Systems, Vol.22, No.8, pp. 2551-2562, 2024. https://doi.org/10.1007/s12555-023-0410-y

- [15] K. Kouno, H. Yamada, and S. Hirose, “Development of active-joint active-wheel high traversability snake-like robot ACM-R4.2,” J. Robot. Mechatron., Vol.25, No.3, pp. 559-566, 2013. https://doi.org/10.20965/jrm.2013.p0559

- [16] D. J. Christensen, U. P. Schultz, and K. Stoy, “A distributed and morphology-independent strategy for adaptive locomotion in self-reconfigurable modular robots,” Robotics and Autonomous Systems, Vol.61, No.9, pp. 1021-1035, 2013. https://doi.org/10.1016/j.robot.2013.05.009

- [17] H. Kurokawa et al., “Self-reconfigurable M-TRAN structures and walker generation,” Robotics and Autonomous Systems, Vol.54, No.2, pp. 142-149, 2014. https://doi.org/10.1016/j.robot.2005.09.023

- [18] P. S. Pagala, M. Ferre, and L. Orona, “Evaluation of modular robot system for maintenance tasks in hot cell,” Fusion Engineering and Design, Vol.89, Nos.9-10, pp. 2309-2313, 2014. https://doi.org/10.1016/j.fusengdes.2014.04.006

- [19] G. Jing, T. Tosun, M. Yim, and H. Kress-Gazit, “Accomplishing high-level tasks with modular robots,” Autonomous Robots, Vol.42, No.7, pp. 1337-1354, 2018. https://doi.org/10.1007/S10514-018-9738-1

- [20] V. Vonásek, M. Saska, L. Winkler, and L. Přeučil, “High-level motion planning for CPG-driven modular robots,” Robotics and Autonomous Systems, Vol.68, pp. 116-128, 2015. https://doi.org/10.1016/j.robot.2015.01.006

- [21] R. Hodoshima et al., “Telerobotic control system to enhance rescue operations for arm-equipped tracked vehicle HELIOS IX,” J. Robot. Mechatron., Vol.26, No.1, pp. 17-33, 2014. https://doi.org/10.20965/jrm.2014.p0017

- [22] S. Sato, T. Song, and Y. Aiyama, “Development of tele-operated underfloor mobile manipulator,” J. Robot. Mechatron., Vol.33, No.6, pp. 1398-1407, 2021. https://doi.org/10.20965/jrm.2021.p1398

- [23] Q. Wu, X. Wang, B. Chen, H. Wu, and Z. Shao, “Development and hybrid force/position control of a compliant rescue manipulator,” Mechatronics, Vol.46, pp. 143-153, 2017. https://doi.org/10.1016/j.mechatronics.2017.08.003

- [24] K. Kuriki and Y. Uchida, “Applying serpentine locomotion to series-connected multi-purpose module system (MMS),” Proc. of the 13th Symp. on the Motion and Vibration Control, Article No.D34, 2013 (in Japanese). https://doi.org/10.1299/jsmemovic.2013.13._D34-1_

- [25] K. Kuriki and Y. Uchida, “Campaign in the series circuit of Multi-Purpose Module System (MMS),” Proc. of Conf. of Tokai Branch, No.133-1, Article No.630, pp. 393-394, 2013 (in Japanese). https://doi.org/10.1299/jsmetokai.2013.62.393

- [26] Y. Uchida, H. Sugiyama, and S. Tachino, “Attitude control methods for quadruped form MMS (MMS-G) to use state feedback control,” Int. J. of Applied Electromagnetics and Mechanics, Vol.52, Nos.3-4, pp. 1553-1560, 2016. https://doi.org/10.3233/JAE-162094

- [27] Y. Uchida, T. Saito, and T. Hatakeyama, “Development of a multi-purpose module system using Mecanum wheel module,” Int. J. of Applied Electromagnetics and Mechanics, Vol.59, No.3, pp. 967-975, 2019. https://doi.org/10.3233/JAE-171096

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.