Paper:

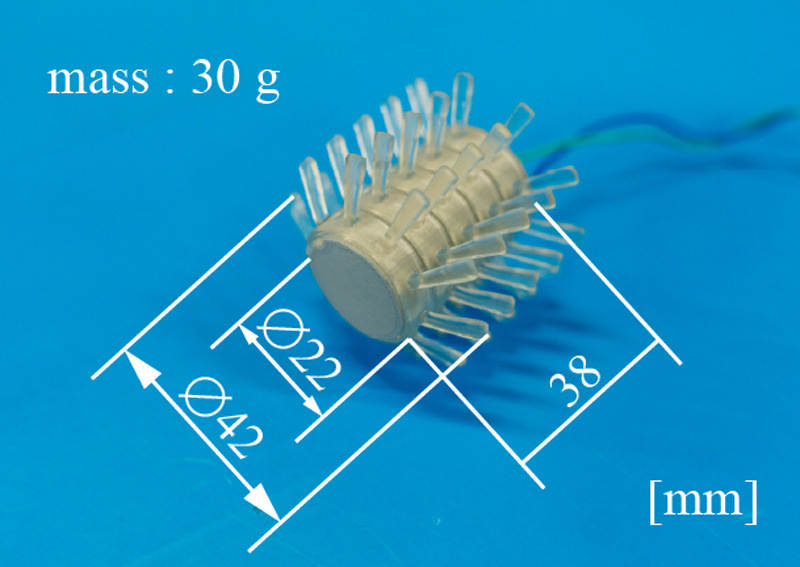

Soft Pipe Inspection Robot with Vibrating Cilia Capable of Underwater Transport

Moses Gladson Selvamuthu

, Ryuto Okada, and Riichiro Tadakuma

, Ryuto Okada, and Riichiro Tadakuma

Yamagata University

4-3-16 Jonan, Yonezawa, Yamagata 992-8510, Japan

The maintenance and inspection of pipelines are crucial in various industries, including oil and gas, water supply, and sewage systems. Traditional methods often involve significant human labor, risks, and costs. Inspired by biological systems, soft robotics offers innovative solutions with the potential to navigate complex and confined environments. This study discusses the development of soft pipe inspection robots equipped with vibration cilia for enhanced mobility and inspection capabilities. The cilia are driven by a vibration motor that can generate controlled vibrations for propulsion. The coordinated movement of the cilia allows the robot to navigate vertically or through complex pipe networks. A notable advancement in this study is the robot’s capability to move under water, which thereby enables its locomotion across stagnant water in pipes. This study also discusses the basic design, modeling, performance analysis, and waterproof compactability verified through experiments. Its flexible design and bio-inspired locomotion offer a safer, more efficient, and cost-effective solution for maintaining vital pipeline infrastructure.

Soft underwater robot with vibrating cilia

- [1] Q. Su, Q. Quan, J. Deng, and H. Yu, “A quadruped micro-robot based on piezoelectric driving,” Sensors, Vol.18, Issue 3, Article No.810, 2018. https://doi.org/10.3390/s18030810

- [2] G. B. Jang, S. Jeon, J. Nam, W. Lee, and G. Jang, “A spiral microrobot performing navigating linear and drilling motions by magnetic gradient and rotating uniform magnetic field for applications in unclogging blocked human blood vessels,” IEEE Trans. on Magnetics, Vol.51, Issue 11, 2015. https://doi.org/10.1109/TMAG.2015.2436913

- [3] S. Guo, Q. Yang, L. Bai, and Y. Zhao, “Development of multiple capsule robots in pipe,” Micromachines, Vol.9, Issue 6, Article No.259, 2018. https://doi.org/10.3390/mi9060259

- [4] H. Koga, Y. Sakata, S. Hirose, and S. Konishi, “Capsule microrobot for targeting in medical diagnostic treatment,” 2011 16th Int. Solid-State Sensors, Actuators and Microsystems Conf., pp. 2835-2838, 2011. https://doi.org/10.1109/TRANSDUCERS.2011.5969392

- [5] K. Isomura and S. Hirose, “Development of articulated spherical wheeled in-pipe robot “ThesV”,” Proc. of the JSME Conf. on Robotics and Mechatronics, 2011. https://doi.org/10.1299/jsmermd.2011._2A2-L08_1

- [6] A. Kakogawa, Y. Komurasaki, and S. Ma, “Shadow-based operation assistant for a pipeline-inspection robot using a variance value of the image histogram,” J. Robot. Mechatron., Vol.31, No.6, pp. 772-780, 2019. https://doi.org/10.20965/jrm.2019.p0772

- [7] M. Arai, T. Takayama, and S. Hirose, “Development of Souryu-III: Connected crawler vehicle for inspection inside narrow and winding spaces,” 2004 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), 2004. https://doi.org/10.1109/IROS.2004.1389328

- [8] T. Kinugasa, T. Haji, K. Yoshida, H. Amano, R. Hayashi, K. Tokuda, and M. Iribe, “Development of flexible mono-tread mobile track using rotational joints,” J. of Intelligent & Robotic Systems, Vol.85, No.2, pp. 229-244, 2017. https://doi.org/10.1007/s10846-016-0374-8

- [9] J. Nagase and F. Fukunaga, “Development of a novel crawler mechanism for pipe inspection,” 42nd Annual Conf. of the IEEE Industrial Electronics Society (IECON 2016), pp. 5873-5878, 2016. https://doi.org/10.1109/IECON.2016.7793844

- [10] Y. Hua, M. Konyo, and S. Tadokoro, “Design and analysis of a pneumatic high-impact force drive mechanism for in-pipe inspection robots,” Advanced Robotics, Vol.30, Issue 19, pp. 1260-1272, 2016. https://doi.org/10.1080/01691864.2016.1205511

- [11] M. Ikeuchi, T. Nakamura, and D. Matsubara, “Development of an in-pipe inspection robot for narrow pipes and elbows using pneumatic artificial muscles,” 2012 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 926-931, 2012. https://doi.org/10.1109/IROS.2012.6385925

- [12] F. Ito, T. Kawaguchi, Y. Yamada, and T. Nakamura, “Development of a Peristaltic-Movement Duct-Cleaning Robot for Application to Actual Environment: Examination of Brush Type and Installation Method to Improve Cleaning Efficiency,” J. Robot. Mechatron., Vol.31, No.6, pp. 781-793, 2019. https://doi.org/10.20965/jrm.2019.p0781

- [13] M. P. Nemitz, P. Mihaylov, T. W. Barraclough, D. Ross, and A. A. Stokes, “Using voice coils to actuate modular soft robots: Wormbot, an example,” Soft Robotics, Vol.3, No.4, pp. 198-204, 2016. https://doi.org/10.1089/soro.2016.0009

- [14] T. Yamamoto, M. Konyo, K. Tadakuma, and S. Tadokoro, “High-speed sliding-inchworm motion mechanism with expansion-type pneumatic hollow-shaft actuators for in-pipe inspections,” Mechatronics, Vol.56, pp. 101-114, 2018. https://doi.org/10.1016/j.mechatronics.2018.10.010

- [15] J. M. Florez, B. Shih, Y. Bai, and J. K. Paik, “Soft pneumatic actuators for legged locomotion,” 2014 IEEE Int. Conf. on Robotics and Biomimetics (ROBIO 2014), pp. 27-34, 2014. https://doi.org/10.1109/ROBIO.2014.7090302

- [16] T. Matsui, S. Murata, and T. Honda, “Fabrication of magnetically driven biopsy mechanism applicable to capsule-type medical device,” J. Robot. Mechatron., Vol.30, No.2, pp. 292-299, 2018. http://dx.doi.org/10.20965/jrm.2018.p0292

- [17] M. Wang, Q. Shi, S. Song, C. Hu, and M. Q.-H. Meng, “A novel relative position estimation method for capsule robot moving in gastrointestinal tract,” Sensors, Vol.19, Issue 12, Article No.2746, 2019. https://doi.org/10.3390/s19122746

- [18] A. Aghakhani, O. Yasa, P. Wrede, and M. Sitti, “Acoustically powered surface-slipping mobile microrobots,” Proc. of the National Academy of Sciences, Vol.117, No.7, pp. 3469-3477, 2020. https://doi.org/10.1073/pnas.1920099117

- [19] S. Kim, S. Lee, J. Lee, B. J. Nelson, L. Zhang, and H. Choi, “Fabrication and manipulation of ciliary microrobots with non-reciprocal magnetic actuation,” Scientific Reports, Vol.6, Article No.30713, 2016. https://doi.org/10.1038/srep30713

- [20] U. K. Cheang, J. Ali, H. Kim, L. Rogowski, and M. J. Kim, “On-surface locomotion of particle based microrobots using magnetically induced oscillation,” Micromachines, Vol.8, Issue 2, Article No.46, 2017. https://doi.org/10.3390/mi8020046

- [21] Y. C. Fu and S. Hirose, “Proposition of surface wave mechanism and its application for watertight mobile robots (mobile robot with special mechanism),” Proc. of JSME annual Conf. on Robotics and Mechatronics (Robomec) 2011, Article No.2A2-L13, 2011. https://doi.org/10.1299/jsmermd.2011._2A2-L13_1

- [22] H. Gu, Q. Boehler, H. Cui, E. Secchi, G. Savorana, C. De Marco, S. Gervasoni, Q. Peyron, T.-Y. Huang, S. Pane et al., “Magnetic cilia carpets with programmable metachronal waves,” Nature Communications, Vol.11, No.1, Article No.2637, 2020. https://doi.org/10.1038/s41467-020-16458-4

- [23] Y. Wu, J. K. Yim, J. Liang, Z. Shao, M. Qi, J. Zhong, Z. Luo, X. Yan, M. Zhang, X. Wang et al., “Insect-scale fast moving and ultrarobust soft robot,” Science Robotics, Vol.4, Issue 32, Article No.eaax1594, 2019. https://doi.org/10.1126/scirobotics.aax1594

- [24] Y. Miyaki and H. Tsukagoshi, “Soft simple compact valve inducing self-excited vibration aimed for mobile robots unnecessary for electricity,” 2018 IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics (AIM), pp. 670-675, 2018. https://doi.org/10.1109/AIM.2018.8452697

- [25] K. Tani, “A mobile machine using piezo vibration and its friction model,” J. of the Robotics Society of Japan, Vol.14, No.8, pp. 1133-1137, 1996. https://doi.org/10.7210/jrsj.14.1133

- [26] K. Nagaoka, R. Takano, T. Izumo, and K. Yoshida, “Ciliary micro-hopping locomotion of an asteroid exploration robot,” Int. Symp. on Artificial Intelligence, Robotics and Automation in Space i-SAIRAS, 2012.

- [27] K. Nagaoka and K. Yoshida, “Modeling and analysis of ciliary micro-hopping locomotion actuated by an eccentric motor in a microgravity,” 2013 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 763-768, 2013. https://doi.org/10.1109/IROS.2013.6696437

- [28] K. Hatazaki, M. Konyo, K. Isaki, S. Tadokoro, and F. Takemura, “Active scope camera for urban search and rescue,” 2007 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 2596-2602, 2007. https://doi.org/10.1109/IROS.2007.4399386

- [29] M. Ishikura, K. Wakana, E. Takeuchi, M. Konyo, and S. Tadokoro, “Running performance evaluation of inchworm drive and vibration drive for active scope camera,” 2011 IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics (AIM), pp. 599-604, 2011. https://doi.org/10.1109/AIM.2011.6027005

- [30] H. Namari, K. Wakana, M. Ishikura, M. Konyo, and S. Tadokoro, “Tube-type active scope camera with high mobility and practical functionality,” 2012 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 3679-3686, 2012. https://doi.org/10.1109/IROS.2012.6386172

- [31] G. Cicconofri, F. Becker, G. Noselli, A. Desimone, and K. Zimmermann, “The inversion of motion of bristle bots: analytical and experimental analysis,” ROMANSY 21 – Robot Design, Dynamics and Control, pp. 225-232, 2016. https://doi.org/10.1007/978-3-319-33714-2_25

- [32] F. Becker, S. Börner, T. Kästner, V. Lysenko, I. Zeidis, and K. Zimmermann, “Spy bristle bot – A vibration-driven robot for the inspection of pipelines,” 58th Ilmenau Scientific Colloquium, 2014.

- [33] V. Lysenko, K. Zimmermann, A. Chigarev, and F. Becker “A mobile vibro-robot for locomotion through pipelines,” 56th IWK, Int. Scientific Colloquium, 2011.

- [34] D. Kim, Z. Hao, A. R. Mohazab, and A. Ansari, “On the forward and backward motion of milli-bristlebots,” Int. J. of Non-Linear Mechanics, Vol.127, Article No.103551, 2020. https://doi.org/10.1016/j.ijnonlinmec.2020.103551

- [35] C. Gandra and P. Tallapragada, “Dynamics of a vibration driven bristlebot,” Dynamic Systems and Control Conf., Vol.59155, Article No.DSCC2019-9018, 2019. https://doi.org/10.1115/DSCC2019-9018

- [36] G. Notomista, S. Mayya, A. Mazumdar, S. Hutchinson, and M. Egerstedt, “A study of a class of vibration-driven robots: Modeling, analysis, control and design of the brushbot,” 2019 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 5101-5106, 2019. https://doi.org/10.1109/IROS40897.2019.8968490

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.