Paper:

Study on Improvement of Docking Mechanism for Docking–Undocking Drones in the Air and Docking Control Using an Onboard Camera

Rikiya Dohi* and Yoshiyuki Higashi**

*Division of Mechanodesign, Kyoto Institute of Technology

Goshokaido-cho, Matsugasaki, Sakyo-ku, Kyoto, Kyoto 606-8585, Japan

**Department of Robotics, Osaka Institute of Technology

1-45 Chayamachi, Kita-ku, Osaka, Osaka 530-8568, Japan

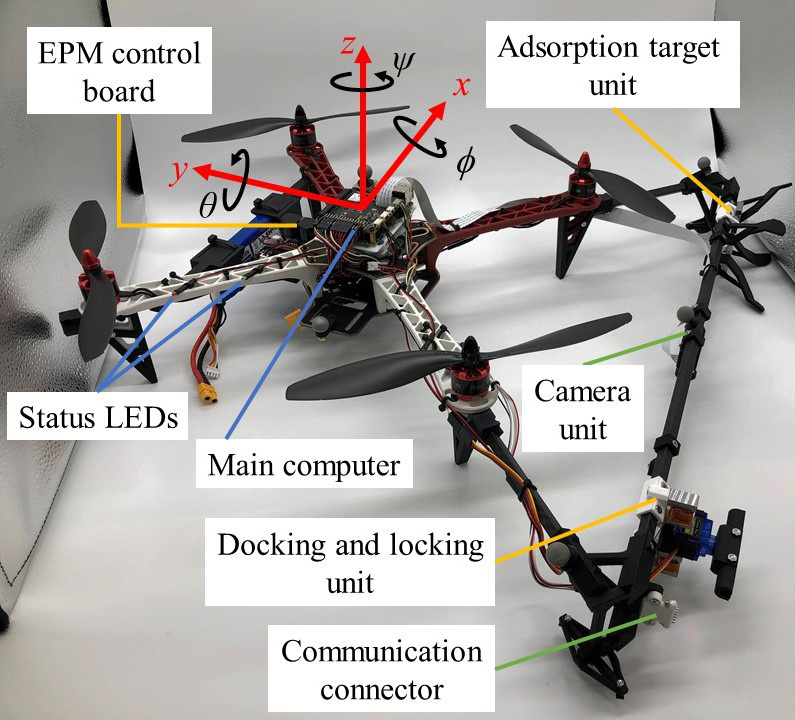

In this study, we developed a docking mechanism for drones that enables docking and undocking in the air for cargo transportation. This capability allows the drone configuration to be adapted depending on the cargo size and shape. We introduced a novel docking mechanism that incorporates magnetic adsorption and a newly engineered locking mechanism. We developed a drone detection system capable of estimating the relative position of a target drone by utilizing an onboard camera to identify the infrared LEDs on the target drone via image processing. Moreover, flight experiments, including detection, docking, and undocking, were performed using a mock drone to demonstrate the effectiveness of the developed system.

Developed docking-undocking drone

- [1] P. L. Gonzalez-R, D. Canca, J. L. Andrade-Pineda, M. Calle, and J. M. Leon-Blanco, “Truck-drone team logistics: A heuristic approach to multi-drop route planning,” Transportation Research Part C: Emerging Technologies, Vol.114, pp. 657-680, 2020. https://doi.org/10.1016/j.trc.2020.02.030

- [2] F. Schiano, P. M. Kornatowski, L. Cencetti, and D. Floreano, “Reconfigurable drone system for transportation of parcels with variable mass and size,” IEEE Robotics and Automation Letters, Vol.7, No.4, pp. 12150-12157, 2022. https://doi.org/10.1109/LRA.2022.3208716

- [3] J. Sugihara, T. Nishio, K. Nagato, M. Nakao, and M. Zhao, “Design, control, and motion strategy of TRADY: Tilted-rotor-equipped aerial robot with autonomous in-flight assembly and disassembly ability,” Advanced Intelligent Systems, Vol.5, No.10, Article No.2300191, 2023. https://doi.org/10.1002/aisy.202300191

- [4] R. Dohi and Y. Higashi, “Integrated control and docking mechanism for docking–undocking drones in the air,” 2022 IEEE Region 10 Conf. (TENCON), 2022. https://doi.org/10.1109/TENCON55691.2022.9978033

- [5] Y. Higashi, S. Akahori, A. Masuda, and K. Takeuchi, “Verification of an EPM system for an aerial inspection robot and close-up image shooting,” Advanced Experimental Mechanics, Vol.1, pp. 179-184, 2016. https://doi.org/10.11395/aem.1.0_179

- [6] S. Akahori, Y. Higashi, A. Masuda, and K. Takeuchi, “Development of a vibration probe foot using an EPM for aerial inspection robots,” Proc. of the 10th Int. Symp. on Advanced Science and Technology in Experimental Mechanics (ISEM’13), Article No.055, 2015.

- [7] S. Akahori, Y. Higashi, and A. Masuda, “Development of an aerial inspection robot with EPM and camera arm for steel structures,” 2016 IEEE Region 10 Conf. (TENCON), pp. 3542-3545, 2016. https://doi.org/10.1109/TENCON.2016.7848716

- [8] K. Takeuchi, A. Masuda, S. Akahori, Y. Higashi, and N. Miura, “A close inspection and vibration sensing aerial robot for steel structures with an EPM-based landing device,” Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure 2017 (SPIE Proc. Vol.10169), Article No.101692U, 2017. https://doi.org/10.1117/12.2260386

- [9] A. Masuda, A. Tanaka, Y. Higashi, and N. Miura, “Reliable activation of an EPM-based clinging device for aerial inspection robots,” J. Robot. Mechatron., Vol.31, No.6, pp. 827-836, 2019. https://doi.org/10.20965/jrm.2019.p0827

- [10] K. Yamazaki, Y. Higashi, A. Masuda, and N. Miura, “Improvement of adsorption force of an EPM-based adsorb device by a suspension,” 2020 IEEE Region 10 Conf. (TENCON), pp. 1182-1186, 2020. https://doi.org/10.1109/TENCON50793.2020.9293917

- [11] Y. Higashi, K. Yamazaki, A. Masuda, N. Miura, and Y. Sawada, “Attractive force estimation of a magnetic adsorption unit for inspection UAVs,” J. Robot. Mechatron., Vol.33, No.6, pp. 1349-1358, 2021. https://doi.org/10.20965/jrm.2021.p1349

- [12] C. Smith et al., “UAV rapidly-deployable stage sensor with electro-permanent magnet docking mechanism for flood monitoring in undersampled watersheds,” HardwareX, Vol.12, Article No.e00325, 2022. https://doi.org/10.1016/j.ohx.2022.e00325

- [13] J. Tugwell et al., “Electropermanent magnetic anchoring for surgery and endoscopy,” IEEE Trans. on Biomedical Engineering, Vol.62, No.3, pp. 842-848, 2015. https://doi.org/10.1109/tbme.2014.2366032

- [14] K. J. McDonald, L. Kinnicutt, A. M. Moran, and T. Ranzani, “Modulation of magnetorheological fluid flow in soft robots using electropermanent magnets,” IEEE Robotics and Automation Letters, Vol.7, No.2, pp. 3914-3921, 2022. https://doi.org/10.1109/LRA.2022.3147873

- [15] P. Zhang, M. Kamezaki, Z. He, H. Sakamoto, and S. Sugano, “EPM-MRE: Electropermanent magnet-magnetorheological elastomer for soft actuation system and its application to robotic grasping,” IEEE Robotics and Automation Letters, Vol.6, No.4, pp. 8181-8188, 2021. https://doi.org/10.1109/LRA.2021.3100939

- [16] D. Saldaña, B. Gabrich, G. Li, M. Yim, and V. Kumar, “ModQuad: The flying modular structure that self-assembles in midair,” 2018 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 691-698, 2018. https://doi.org/10.1109/ICRA.2018.8461014

- [17] G. Li et al., “ModQuad-Vi: A vision-based self-assembling modular quadrotor,” 2019 Int. Conf. on Robotics and Automation (ICRA), pp. 346-352, 2019. https://doi.org/10.1109/ICRA.2019.8794056

- [18] R. Oung, F. Bourgault, M. Donovan, and R. D’Andrea, “The distributed flight array,” 2010 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 601-607, 2010. https://doi.org/10.1109/ROBOT.2010.5509882

- [19] R. Oung, M. Picallo Cruz, and R. D’Andrea, “A parameterized control methodology for a modular flying vehicle,” 2012 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 532-538, 2012. https://doi.org/10.1109/IROS.2012.6385706

- [20] M. Kriegleder, R. Oung, and R. D’Andrea, “Distributed altitude and attitude estimation from multiple distance measurements,” 2012 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 3626-3632, 2012. https://doi.org/10.1109/IROS.2012.6385658

- [21] M. Kriegleder, S. T. Digumarti, R. Oung, and R. D’Andrea, “Rendezvous with bearing-only information and limited sensing range,” 2015 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 5941-5947, 2015. https://doi.org/10.1109/ICRA.2015.7140032

- [22] H. Lim, J. Park, D. Lee, and H. J. Kim, “Build your own quadrotor: Open-source projects on unmanned aerial vehicles,” IEEE Robotics & Automation Magazine, Vol.19, No.3, pp. 33-45, 2012. https://doi.org/10.1109/MRA.2012.2205629

- [23] A. B. Junaid, A. D. D. C. Sanchez, J. B. Bosch, N. Vitzilaios, and Y. Zweiri, “Design and implementation of a dual-axis tilting quadcopter,” Robotics, Vol.7, No.4, Article No.65, 2018. https://doi.org/10.3390/robotics7040065

- [24] M. Rabah, A. Rohan, S. A. S. Mohamed, and S.-H. Kim, “Autonomous moving target-tracking for a UAV quadcopter based on Fuzzy-PI,” IEEE Access, Vol.7, pp. 38407-38419, 2019. https://doi.org/10.1109/ACCESS.2019.2906345

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.