Paper:

Development and Application of Shape-Memory Polymer and Alloy Composite Sheets

Kazuto Takashima*1

, Yuta Okamura*1, Junya Nagaishi*2, Hiroki Cho*2, Toshiro Noritsugu*3, and Toshiharu Mukai*4

, Yuta Okamura*1, Junya Nagaishi*2, Hiroki Cho*2, Toshiro Noritsugu*3, and Toshiharu Mukai*4

*1Graduate School of Life Science and Systems Engineering, Kyushu Institute of Technology

2-4 Hibikino, Wakamatsu-ku, Kitakyushu 808-0196, Japan

*2Faculty of Environmental Engineering, The University of Kitakyushu

1-1 Hibikino, Wakamatsu-ku, Kitakyushu, Fukuoka 808-0135, Japan

*3Mimasaka University

50 Kitazonocho, Tsuyama, Okayama 708-8511, Japan

*4Department of Information Engineering, Faculty of Information Engineering, Meijo University

1-501 Shiogamaguchi, Tenpaku-ku, Nagoya 468-8502, Japan

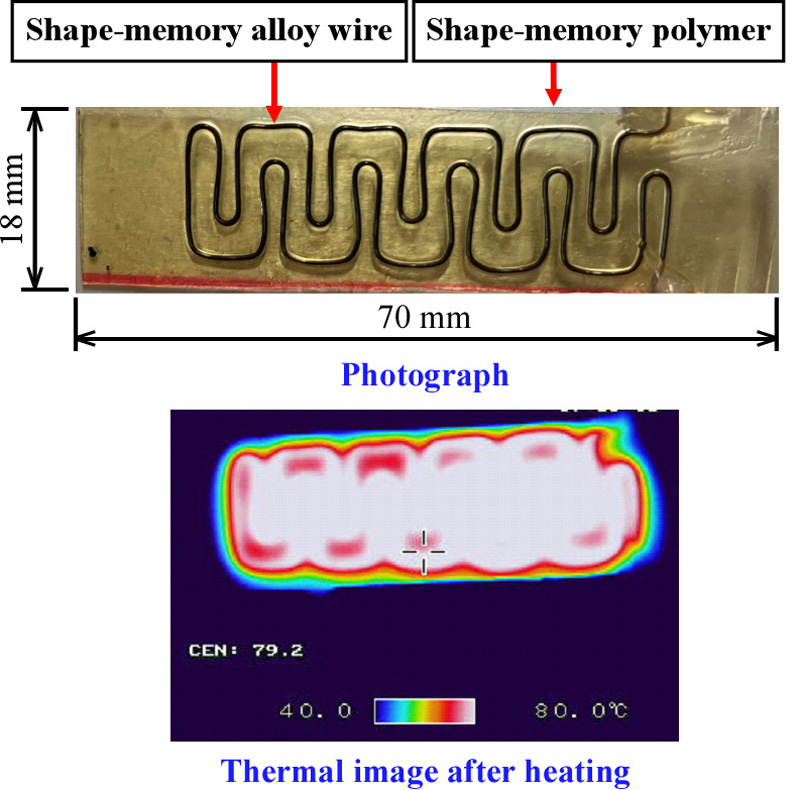

The authors previously developed a flexible and multi-degree-of-freedom pneumatic artificial rubber muscle that uses shape-memory polymer (SMP) sheets with an embedded electrical heating wire. The bending direction and initial shape of the muscle can be changed by utilizing the large difference in the elastic modulus below and above the glass transition temperature, shape fixity, and shape recovery of SMPs. In this study, to improve performance, we propose a shape-memory composite (SMC) sheet that consists of SMP sheets with an embedded shape-memory alloy (SMA) wire used as an electric heating wire. The mechanical properties of the previously developed SMP sheets and the proposed SMC sheets are compared through shape recovery, bending, and tensile tests using prototypes. The motion of the artificial muscle with various samples attached is evaluated through an isometric test and bending angle measurements. The experimental results confirm that the use of the SMA wire improves the production reproducibility and shape recovery of the SMP sheets without degrading other mechanical properties or actuator performance.

Proposed shape-memory composite sheet

- [1] K. Takashima, K. Sugitani, N. Morimoto, S. Sakaguchi, T. Noritsugu, and T. Mukai, “Pneumatic Artificial Rubber Muscle Using Shape-Memory Polymer Sheet with Embedded Electrical Heating Wire,” Smart Materials and Structures, Vol.23, No.12, Article No.125005, 2014. https://doi.org/10.1088/0964-1726/23/12/125005

- [2] K. Takashima, D. Iwamoto, S. Oshiro, T. Noritsugu, and T. Mukai, “Characteristics of pneumatic artificial rubber muscle using two shape-memory polymer sheets,” J. Robot. Mechatron., Vol.33, No.3, pp. 653-664, 2021. https://doi.org/10.20965/jrm.2021.p0653

- [3] Y. Okamura, K. Takashima, T. Noritsugu, and T. Mukai, “Improved Method of Preparation for Shape-Memory Polymer Sheet With Embedded Electrical Heating Wire for Use in Pneumatic Artificial Rubber Muscle,” Proc. of the SICE Annual Conf. 2023, pp. 582-587, 2023. http://doi.org/10.23919/SICE59929.2023.10354241

- [4] K. Takashima, Y. Okamura, D. Iwamoto, T. Noritsugu, and T. Mukai, “Development of pneumatic artificial rubber muscle using segmented shape-memory polymer sheets,” J. Robot. Mechatron., Vol.35, No.1, pp. 113-124, 2023. https://doi.org/10.20965/jrm.2023.p0113

- [5] K. Takashima, T. Noritsugu, J. Rossiter, S. Guo, and T. Mukai, “Curved Type Pneumatic Artificial Rubber Muscle Using Shape-Memory Polymer,” J. Robot. Mechatron., Vol.24, No.3, pp. 472-479, 2012. https://doi.org/10.20965/jrm.2012.p0472

- [6] J. M. Jani, M. Leary, A. Subic, and M. A. Gibson, “A Review of Shape Memory Alloy Research, Applications and Opportunities,” Materials and Design (1980–2015), Vol.56, pp. 1078-1113, 2014. https://doi.org/10.1016/j.matdes.2013.11.084

- [7] T. P. Chenal, J. C. Case, J. Paik, and R. K. Kramer, “Variable Stiffness Fabrics with Embedded Shape Memory Materials for Wearable Applications,” 2014 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 2827-2831, 2014. https://doi.org/10.1109/IROS.2014.6942950

- [8] H. Tobushi, S. Hayashi, Y. Sugimoto, and K. Date, “Two-Way Bending Properties of Shape Memory Composite With SMA and SMP,” Materials, Vol.2, No.3, pp. 1180-1192, 2009. https://doi.org/10.3390/ma2031180

- [9] P. Ghosh, A. Rao, and A. R. Srinivasa, “Design of Multi-State and Smart-Bias Components Using Shape Memory Alloy and Shape Memory Polymer Composites,” Materials and Design, Vol.44, pp. 164-171, 2013. https://doi.org/10.1016/j.matdes.2012.05.063

- [10] J. Rossiter, K. Takashima, and T. Mukai, “Thermal Response of Novel Shape Memory Polymer-Shape Memory Alloy Hybrids,” Proc. SPIE, Vol.9058, Behavior and Mechanics of Multifunctional Materials and Composites 2014, Article No.905810, 2014. https://doi.org/10.1117/12.2045175

- [11] H. Du, Y. Yao, Y. Liu, and W. Zhao, “Two-Way Shape Memory Effect of a Shape Memory Composite Strip,” Applied Sciences, Vol.13, Article No.4715, 2023. https://doi.org/10.3390/app13084715

- [12] H. Meng, H. Mohamadian, M. Stubblefield, D. Jerro, S. Ibekwe, S-S. Pang, and G. Li, “Various Shape Memory Effects of Stimuli-Responsive Shape Memory Polymers,” Smart Materials and Structures, Vol.22, No.9, Article No.093001, 2013. https://doi.org/10.1088/0964-1726/22/9/093001

- [13] J. Shintake, V. Cacucciolo, D. Floreano, and H. Shea, “Soft robotic grippers,” Advanced Materials, Vol.30, Issue 29, Article No.1707035, 2018. https://doi.org/10.1002/adma.201707035

- [14] K. Takashima, T. Imazawa, and H. Cho, “Variable-Stiffness and Deformable Link Using Shape-Memory Material and Jamming Transition Phenomenon,” J. Robot. Mechatron., Vol.34, No.2, pp. 466-477, 2022. https://doi.org/10.20965/jrm.2022.p0466

- [15] K. Takashima, H. Kamizono, M. Takenaka, and T. Mukai, “Force Sensor Utilizing Stiffness Change of Shape-Memory Polymer Based on Temperature,” ROBOMECH J., Vol.4, Article No.17, 2017. https://doi.org/10.1186/s40648-017-0086-2

- [16] K. Takashima, R. Miyazaki, and T. Mukai, “Surface Shape Changeable Tactile Sensor Using Shape-Memory Polymer,” 2021 60th Annual Conf. of the Society of Instrument and Control Engineers of Japan (SICE), pp. 1166-1171, 2021.

- [17] Y. An, H. Yoshida, Y. Jing, T. Liang, and H. Okuzaki, “Ionic Shape Memory Polymer Gels as Multifunctional Sensors,” Soft Matter, Vol.18, Article No.6791, 2022. https://doi.org/10.1039/D2SM00515H

- [18] S. Yahara, S. Wakimoto, T. Kanda, and K. Matsushita, “McKibben Artificial Muscle Realizing Variable Contraction Characteristics Using Helical Shape-Memory Polymer Fibers,” Sensors and Actuators: A Physical, Vol.295, pp. 637-642, 2019. https://doi.org/10.1016/j.sna.2019.06.012

- [19] A. Shimamoto and Y. Furuya, “Active Control of Crack-Tip Stress Intensity by Contraction of Shape Memory TiNi Fibers Embedded in Epoxy Matrix Composite: Dependency of Stress Intensity Factor on Cracktip Domain Size,” Proc. of the 1999 Int. Conf. on Composite Materials, Vol.6, pp. 493-499, 1997.

- [20] G. Murasawa, S. Yoneyama, K. Tohgo, and M. Takashi, “Distribution of Deformation and Internal Stress in Shape Memory Alloy Composite,” Trans. of the JSME, Ser. C, Vol.71, No.705, pp. 780-788, 2005 (in Japanese). https://doi.org/10.1299/kikaia.71.780

- [21] D. Rus and M. T. Tolley, “Design, Fabrication and Control of Soft Robots,” Nature, Vol.521, Article No.7553, pp. 467-475, 2015. https://doi.org/10.1038/nature14543

- [22] A. Miriyev, K. Stack, and H. Lipson, “Soft Material for Soft Actuators,” Nature Communications, Vol.8, Article No.596, 2017. https://doi.org/10.1038/s41467-017-00685-3

- [23] Y. Haga, T. Mineta, T. Matsunaga, and N. Tsuruoka, “Micro-Robotic Medical Tools Employing SMA Actuators for Use in the Human Body,” J. Robot. Mechatron., Vol.34, No.6, pp. 1233-1244, 2022. https://doi.org/10.20965/jrm.2022.p1233

- [24] K. Takashima, H. Suzuki, T. Imazawa, and H. Cho, “Motion Evaluation of Variable-Stiffness Link Based on Shape-Memory Alloy and Jamming Transition Phenomenon,” J. Robot. Mechatron., Vol.36, No.1, pp. 181-189, 2024. https://doi.org/10.20965/jrm.2024.p0181

- [25] The Japan Society of Mechanical Engineers (Eds.), “JSME mechanical engineers’ handbook DVD-ROM,” Maruzen Publishing, 2014 (in Japanese).

- [26] M. Aragane, T. Noritsugu, M. Takaiwa, D. Sasaki, and S. Naomoto, “Development of Sheet-Like Curved Type Pneumatic Rubber Muscle and Application to Elbow Power Assist Wear,” J. Robotics Society of Japan, Vol.26, Issue 6, pp. 674-682, 2008 (in Japanese). https://doi.org/10.7210/jrsj.26.674

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.