Paper:

Coverage Motion Planning Based on 3D Model’s Curved Shape for Home Cleaning Robot

Yuki Sakata and Takuo Suzuki

Aichi Prefectural University

1522-3 Ibaragabasama, Nagakute, Aichi 480-1198, Japan

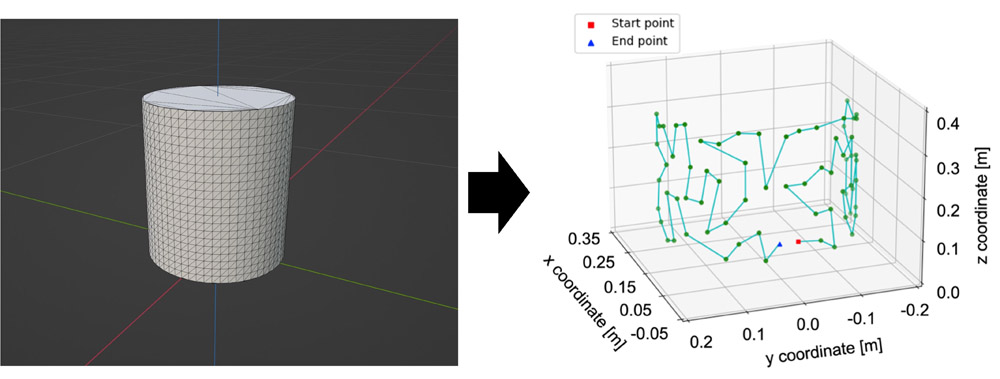

Research on the automated control of robots for wiping curved surfaces includes studies on cleaning contaminated areas and controlling the end-effector posture to apply a constant force along curved surfaces. However, such robots should also clean difficult-to-find contaminants such as dust and dirt. One of previous studies has considered motion generation as a generalized traveling salesman problem. In particular, a point cloud is acquired from an RGBD camera, and a large graph is created to represent the surface based on the point cloud. The system then finds an appropriate end-effector posture for each node and sets up multiple coordinate systems. Consequently, an efficient cleaning motion can be generated; however, path generation using the previous study is a highly time-consuming process. Therefore, in this study, a 3D model is used to generate cleaning actions more efficiently. A point cloud is then generated from the mesh data of the 3D model, based on which the surface is represented as a simple graph that can be solved as a traveling salesman problem, thereby reducing the computational time. The optimal end-effector posture is determined based on the shape of the surface and is set as the coordinate system for each node. Finally, experiments are conducted to compare the cleaning results with the previous study results, thereby verifying that results can be obtained in less than one-tenth the computational time required for the previous study results.

A cleaning path generated based on a 3D model

- [1] T. Inamura et al., “Realization of Trash Separation of Bottles and Cans for Humanoids using Eyes, Hands and Ears,” J. of the Robotics Society of Japan, Vol.25, No.6, pp. 813-821, 2007. https://doi.org/10.7210/jrsj.25.813

- [2] H. Sasatake et al., “Imitation Learning System Design with Small Training Data for Flexible Tool Manipulation,” J. Robot. Mechatron., Vol.15, No.5, pp. 669-677, 2021. https://doi.org/10.20965/ijat.2021.p0669

- [3] T. Suzuki et al., “Toilet Cleaning Service by Mobile Robot Equipped With RGB-D Camera and Single Arm,” Proc. of JSME annual Conf. on Robotics and Mechatronics (Robomech), 2020. https://doi.org/10.1299/jsmermd.2020.2A1-G07

- [4] J. Redmon et al., “You Only Look Once: Unified, Real-Time Object Detection,” CVPR, pp. 779-788(216), 2015. https://doi.org/abs/1506.02640

- [5] R. Miyagusuku et al., “Toward Autonomous Garbage Collection Robots in Terrains with Different Elevations,” J. Robot. Mechatron., Vol.32, No.6, pp. 1164-1172, 2020. https://doi.org/10.20965/jrm.2020.p1164

- [6] Y. Fukazawa et al., “Region Exploration Path Planning for a Mobile Robot Expressing Working Area By Grid Points,” Trans. of the Society of Instrument and Control Engineers, Vol.39, No.11, pp. 1055-1060, 2003. https://doi.org/10.1109/ROBOT.2003.1241960

- [7] T. Sasaki et al., “Adaptive Path Planning for Cleaning Robots Considering Dust Distribution,” J. Robot. Mechatron., Vol.30, No.1, pp. 5-14, 2018. https://doi.org/10.20965/jrm.2018.p0005

- [8] Y. Katsuki et al., “Reliable Glass Cleaning Motion of a Wall Climbing Robot Using a Dirt Detect Sensor,” Trans. of the Japan Society of Mechanical Engineers, C, Vol.78, No.786, pp. 557-567, 2012. https://doi.org/10.1299/kikaic.78.557

- [9] D. Leidner et al., “Knowledge-enabled parameterization of whole-body control strategies for compliant service robots,” Autonomous Robots, Vol.40, No.3, pp. 519-536, 2016. https://doi.org/10.1007/s10514-015-9523-3

- [10] J. Kim et al., ““iCub, clean the table!” A robot learning from demonstration approach using deep neural networks,” 2018 IEEE Int. Conf. on Autonomous Robot Systems and Competitions (ICARSC), pp. 3-9, 2018. https://doi.org/10.1109/ICARSC.2018.8374152

- [11] J. Moura et al., “Automation of train cab front cleaning with a robot manipulator,” IEEE Robot. Autom. Lett., Vol.3, No.4, pp. 3058-3065, 2018. https://doi.org/10.1109/LRA.2018.2849591

- [12] N. Saito et al., “Wiping 3Dobjects using Deep Learning Model based on Image/Force/Joint Information,” 2020 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 10152-10157, 2020. https://doi.org/10.1109/IROS45743.2020.9341275

- [13] A. M. Kabir et al., “Automated Planning for Robotic Cleaning Using Multiple Setups and Oscillatory Tool Motions,” IEEE Trans. on Automation Science and Engineering, Vol.14, No.3, pp. 1364-1377, 2017. https://doi.org/10.1109/TASE.2017.2665460

- [14] M. Luo et al., “Surface Optimal Path Planning Using an Extended Dijkstra Algorithm,” IEEE Access, Vol.8, pp. 147827-147838, 2020. https://doi.org/10.1109/ACCESS.2020.3015976

- [15] J. Hess et al., “Null Space Optimization for Effective Coverage of 3D Surfaces using blueundant Manipulators,” IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 1923-1928, 2012. https://doi.org/10.1109/IROS.2012.6385960

- [16] A. Yamaguchi, “Accuracy Improvement of 3D Point Cloud Registration by Partial Matching Method Considering Hidden Surfaces,” Aichi Prefectural University Graduate School of Information Science and Technology thesis, 2021.

- [17] S. Rusinkiewicz and M. Levoy, “Efficient variants of the ICP algorithm,” Proc. 3rd Int. Conf. 3-D Digit. Imag. Modeling, pp. 145-152, 2001. https://doi.org/10.1109/IM.2001.924423

- [18] T. Yamamoto et al., “Development of Human Support Robot as the research platform of a domestic mobile manipulator,” ROBOMECH J., Vol.6, Article No.4, 2019. https://doi.org/10.1186/s40648-019-0132-3

- [19] N. Ando, “Technology Challenge and Competition Rules in FCSC (Future Convenience Store Challenge),” Instrument and Control Engineers, Vol.61, No.6, pp. 415-418, 2022. https://doi.org/10.11499/sicejl.61.415

- [20] G. A. Garcia Rcardez et al., “Team NAIST-RITS-Panasonic at the Future Convenience Store Challenge – Our Approach from 2018 to 2021 –,” J. of The Society of Instrument and Control Engineers, Vol.61, No.6, pp. 422-425, 2022. https://doi.org/10.11499/sicejl.61.422

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.