Paper:

A Three-Fingered Hand with a Suction Gripping System for Warehouse Automation

Shun Hasegawa, Kentaro Wada, Kei Okada, and Masayuki Inaba

Graduate School of Information Science and Technology, The University of Tokyo

7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan

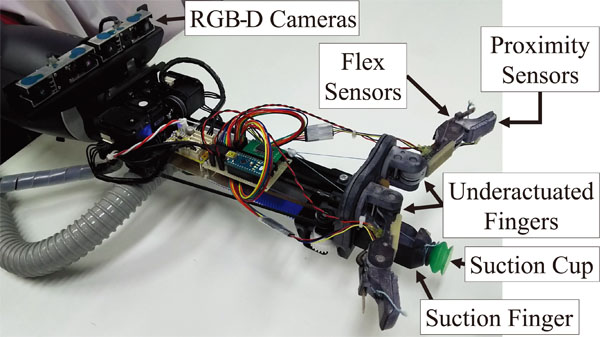

For warehouse automation, stocking items in storage shelves (stowing stage) and picking them off the shelves (picking stage) should be automated. To achieve this, we propose a Suction Pinching Hand, an unstable-to-stable transformation (UST) strategy, and an entrance passing (EP) strategy. The Suction Pinching Hand has two underactuated fingers and one extendable and foldable suction finger whose fingertip has a suction cup. The suction finger is useful during the picking stage to enter and manipulate various objects in a cluttered narrow space, with such spaces being typical in efficient warehouses. As this manipulation is sometimes unstable, the underactuated fingers are used simultaneously to stabilize the grasp after the suction finger moves the object to a relatively open space. The UST strategy realizes the transition from unstable object manipulation in a narrow space to stabilization in a relatively open space. In the stowing stage, proximity sensors in the underactuated fingers are used to sense when the object is touched, for securing a direct pinching motion executable in the stowing stage. Finally, the EP strategy ensures that the picked object is able to pass through the entrance of the shelf bin and be successfully stowed. Experiments demonstrate both the ability of our robot hand to grasp various objects stably and safely, and the effectiveness of the UST and EP strategies during the picking and stowing stages.

Overview of the Suction Pinching Hand

- [1] P. Baker and Z. Halim, “An exploration of warehouse automation implementations: cost, service and flexibility issues,” Supply Chain Management, Vol.12, No.2, pp. 129-138, 2007.

- [2] P. R. Wurman, R. D’Andrea, and M. Mountz, “Coordinating hundreds of cooperative, autonomous vehicles in warehouses,” AI Magazine, Vol.29, No.1, pp. 9-20, 2008.

- [3] C. Hernandez, M. Bharatheesha, W. Ko, H. Gaiser, J. Tan, K. v. Deurzen, M. d. Vries, B. Van Mil, J. v. Egmond, R. Burger et al., “Team Delft’s robot winner of the Amazon Picking Challenge 2016,” S. Behnke, R. Sheh, S. Sariel, and D. D. Lee (Eds.), “RoboCup 2016: Robot World Cup XX,” Springer, pp. 613-624, 2016.

- [4] R. Tella, J. R. Birk, and R. B. Kelley, “General Purpose Hands for Bin-Picking Robots,” IEEE Trans. on Systems, Man, and Cybernetics, Vol.12, No.6, pp. 828-837, 1982.

- [5] K. Rahardja and A. Kosaka, “Vision-based bin-picking: recognition and localization of multiple complex objects using simple visual cues,” Proc. of the 1996 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, Vol.3, pp. 1448-145, 1996.

- [6] N. Shroff, Y. Taguchi, O. Tuzel, A. Veeraraghavan, S. Ramalingam, and H. Okuda, “Finding a needle in a specular haystack,” 2011 IEEE Int. Conf. on Robotics and Automation, pp. 5963-5970, May 2011.

- [7] A. Saxena, L. L. S. Wong, and A. Y. Ng, “Learning Grasp Strategies with Partial Shape Information,” Proc. of the 23rd National Conf. on Artificial Intelligence (AAAI’08), Vol.3, pp. 1491-1494, 2008.

- [8] D. Fischinger, M. Vincze, and Y. Jiang, “Learning grasps for unknown objects in cluttered scenes,” 2013 IEEE Int. Conf. on Robotics and Automation, pp. 609-616, May 2013.

- [9] C. Eppner, S. Höfer, R. Jonschkowski, R. Martín-Martín, A. Sieverling, V. Wall, and O. Brock, “Lessons from the Amazon Picking Challenge: Four Aspects of Building Robotic Systems,” Proc. of Robotics: Science and Systems, Ann Arbor, Michigan, June 2016.

- [10] Z. Littlefield, S. Zhu, H. Kourtev, Z. Psarakis, R. Shome, A. Kimmel, A. Dobson, A. F. D. Souza, and K. E. Bekris, “Evaluating end-effector modalities for warehouse picking: A vacuum gripper vs a 3-finger underactuated hand,” 2016 IEEE Int. Conf. on Automation Science and Engineering, pp. 1190-1195, August 2016.

- [11] S. Hasegawa, K. Wada, Y. Niitani, K. Okada, and M. Inaba, “A three-fingered hand with a suction gripping system for picking various objects in cluttered narrow space,” 2017 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 1164-1171, September 2017.

- [12] N. Correll, K. E. Bekris, D. Berenson, O. Brock, A. Causo, K. Hauser, K. Okada, A. Rodriguez, J. M. Romano, and P. R. Wurman, “Analysis and Observations From the First Amazon Picking Challenge,” IEEE Trans. on Automation Science and Engineering, Vol.15, No.1, pp. 172-188, January 2018.

- [13] K. T. Yu, N. Fazeli, N. C. Dafle, O. Taylor, E. Donlon, G. D. Lankenau, and A. Rodriguez, “A Summary of Team MIT’s Approach to the Amazon Picking Challenge 2015,” CoRR, abs/1604.03639, 2016.

- [14] K. Yamaguchi, Y. Hirata, and K. Kosuge, “Development of robot hand with suction mechanism for robust and dexterous grasping,” 2013 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 5500-5505, November 2013.

- [15] H. Zhu, Y. Y. Kok, A. Causo, K. J. Chee, Y. Zou, S. O. K. Al-Jufry, C. Liang, I. M. Chen, C. C. Cheah, and K. H. Low, “Strategy-based robotic item picking from shelves,” 2016 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 2263-2270, October 2016.

- [16] Y. Aiyama, M. Inaba, and H. Inoue, “Pivoting: A new method of graspless manipulation of object by robot fingers,” Proc. of the 1993 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, Vol.1, pp. 136-143, July 1993.

- [17] K. M. Lynch, “Nonprehensile robotic manipulation: controllability and planning,” Carnegie Mellon University, 1996.

- [18] F. Chen, K. Sekiyama, B. Sun, P. Di, J. Huang, H. Sasaki, and T. Fukuda, “Design and Application of an Intelligent Robotic Gripper for Accurate and Tolerant Electronic Connector Mating,” J. Robot. Mechatron., Vol.24, No.3, pp. 441-451, 2012.

- [19] R. Patel and N. Correll, “Integrated force and distance sensing using elastomer-embedded commodity proximity sensors,” Proc. of Robotics: Science and Systems, 2016.

- [20] J. Long, E. Shelhamer, and T. Darrell, “Fully convolutional networks for semantic segmentation,” Proc. of the IEEE Conf. on Computer Vision and Pattern Recognition, pp. 3431-3440, 2015.

- [21] K. Wada, K. Okada, and M. Inaba, “Probabilistic 3D multilabel real-time mapping for multi-object manipulation,” 2017 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 5092-5099, September 2017.

- [22] H. Zhang, P. Long, D. Zhou, Z. Qian, Z. Wang, W. Wan, D. Manocha, C. Park, T. Hu, C. Cao, Y. Chen, M. Chow, and J. Pan, “DoraPicker: An autonomous picking system for general objects,” 2016 IEEE Int. Conf. on Automation Science and Engineering, pp. 721-726, August 2016.

- [23] J. Morrow, H. Shin, C. Phillips-Grafflin, S. Jang, J. Torrey, R. Larkins, S. Dang, Y. Park, and D. Berenson, “Improving Soft Pneumatic Actuator fingers through integration of soft sensors, position and force control, and rigid fingernails,” 2016 IEEE Int. Conf. on Robotics and Automation, pp. 5024-5031, May 2016.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.