Paper:

Development of a Micro-Manipulator for Bio-Targets Using Micro Flows

Jean-Charles Pelletier*, Hisayuki Aoyama*, Yuuka Irie*, Chisato Kanamori*, and Nadine Piat**

*Department of Mechanics, The University of Electro-Communication

1-5-1 Chofugaoka, Chofu, Chofu-shi, Tokyo 183-8585, Japan

**FEMTO-ST Institute

24 rue Alain Savary, 25000 Besançon, France

In the field of bio-engineering, there is a need for a specialized manipulator that protect targets from hard physical contact. The solution proposed in this paper is a system that controls micro flows to manipulate a micro-sized bio-target. The manipulation principle and system structure are presented. In addition, a simple model that uses physically observable parameters is constructed to capture the flow-target interactions following a chemically assisted flow visualization. The experimental results of a prototype are presented, and the feasibility is discussed. The purpose of this paper is to prove the feasibility of this manipulation method. Further developments are introduced, highlighting the full potential of the prototype.

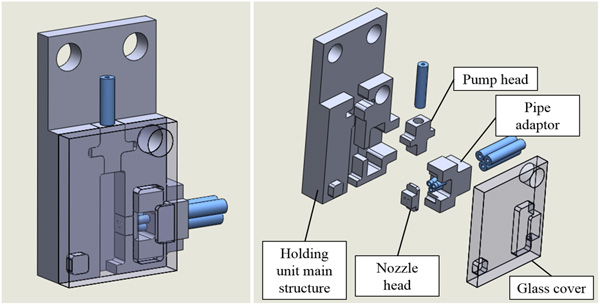

Design of the 3 flow manipulator

- [1] T. Tanikawa, M. Kawai, N. Koyachi, T. Arai, T. Ide, S. Kaneko, R. Ohta, and T. Hirose, “Force Control System for Autonomous Micro Manipulation,” J. Robot. Mechatron., Vol.14, No.3, pp. 212-220, 2002.

- [2] Y. Shen, M. Nakajima, M. R. Ahmad, T. Fukuda, S. Kojima, and M. Homma, “Single Cell Penetration using Nano-pipette by E-SEM Nanorobotic Manipulation System,” 2009 IEEE Int. Conf. on Mechatronics and Automation, 2009.

- [3] C. Gosse and V. Croquette, “Magnetic Tweezers: Micromanipulation and Force Measurement at the Molecular Level,” Biophysical J., Vol.82, pp. 3314-3329, 2002.

- [4] Y. Zhang et al., “Autonomous robotic pick-and-place of micro objects,” IEEE Trans. on Robotics, Vol.26, pp. 200-207, 2010.

- [5] E. T. Papoutsakis, “Fluid-mechanical damage of animal cells in bioreactors,” Trends ins Biotechnology, Vol.9, No.1, pp. 427-437, 1991.

- [6] J. J. Chalmers, “Mixing, aeration and cell damage, 30+ years later: what we learned, how it affected the cell culture industry and what we would like to know more about,” Current Opinion in Chemical Engineering, Vol.10, pp. 94-102, 2015.

- [7] K. Kim et al., “Nanonewton force-controlled manipulation of biological cells using a monolithic MEMS microgripper with two-axis force feedback,” J. of Micromechanics and Microengineering, Vol.18, No.5, 055013, 2008.

- [8] W. Wang, Y. Huang, M. Grujicic, and D. B. Chrisey, “Study of Impact-Induced Mechanical Effects in Cell Direct Writing Using Smooth Particle Hydrodynamic Method,” J. of Manufacturing Science and Engineering, Vol.130, No.2, 2008.

- [9] F. Arai, T. Endo, R. Yamauchi, and T. Fukuda, “3D 6DOF Manipulation of Microbead by Laser Tweezers,” J. Robot. Mechatron., Vol.18, No.2, pp. 153-159, 2006.

- [10] K. Y. Chen, A. T. Lee, C. C. Hung, J. S. Huang, and Y. T. Yang, “Transport and Trapping in Two-Dimensional Nanoscale Plasmonic Optical Lattice,” Nano Lett., Vol.13, No.9, pp. 4118-4122, 2013.

- [11] M. P. MacDonald, G. C. Spalding, and K. Dholakia, “Microfluidic sorting in an optical lattice,” Nature, Letters to Nature, Vol.426, pp. 421-423, 2003.

- [12] G. Volpe, L. Kurz, A. Callegari, G. Volpe, and S. Gigan, “Speckle Optical Tweezers: Micromanipulation with Random Light Fields,” Optics Express, Vol.22, No.15, pp. 18159-18167, 2014.

- [13] T. Yasukawa, Y. Yoshida, H. Hatanaka, and F. Mizutani, “Line Patterning with Microparticles at Different Positions in a Single Device Based on Negative Dielectrophoresis,” J. Robot. Mechatron., Vol.25, No.4, pp. 650-656, 2013.

- [14] L. M. Barrett, A. J. Skulan, A. K. Singh, E. B. Cummings, and G. J. Fiechtner, “Dielectrophoretic Manipulation of Particles and Cells Using Insulating Ridges in Faceted Prism Microchannels,” Analytical Chemistry, Vol.77, No.21, pp. 6798-6804, 2005.

- [15] H. Maruyama, F. Arai, and T. Fukuda, “On-Chip Microparticle Manipulation Using Disposable Magnetically Driven Microdevices,” J. Robot. Mechatron., Vol.18, No.3, pp. 264-270, 2006.

- [16] Z. Ye, E. Diller, and M. Sitti, “Micro-manipulation using rotational fluid flows induced by remote magnetic micromanipulators,” J. of Applied Physics, Vol.112, 064912, 2012.

- [17] B. Zhu, C. Fei, C. Wang, Y. Zhu, X. Yang, H. Zheng, Q. Zhou, and K. K. Shung, “Self-Focused AlScN Film Ultrasound Transducer for Individual Cell Manipulation,” American Chemical Society Sensors, Vol.2, No.1, pp. 172-177, 2017.

- [18] H. V. Phan, T. Alan, and A. Neild, “Droplet Manipulation Using Acoustic Streaming Induced by a Vibrating Membrane,” American Chemical Society Sensors, Vol.88, pp. 5696-5703, 2016.

- [19] M. Hagiwara, M. Niimi, T. Kawahara, Y. Yamanishi, H. Nakanishi, and F. Arai, “On-Chip Particle Sorting into Multiple Channels by Magnetically Driven Microtools,” J. Robot. Mechatron., Vol.23, pp. 370-377, 2011.

- [20] Y. Yalikun, Y. Akiyama, T. Hoshino, and K. Morishima, “A Bio-Manipulation Method Base on the Hydrodynamic Force of Multiple Microfluidic Streams,” J. Robot. Mechatron., Vol.25, pp. 611-618, 2013.

- [21] J. C. Pelletier, Y. Irie, C. Kanamori, H. Aoyama, and N. Piat, “Chemically Assisted Visualization for Fluidic Micro Manipulation,” IEEE ICMA Takamatsu, Japan, pp. 799-801, 2017.

- [22] E. Moeendarbary and A. R. Harris, “Cell mechanics: principles, practices, and prospects,” WIREs Syst Biol Med, Vol.6, pp. 371-388, 2014.

- [23] J. Liang, “A Review of Multiscale Science: Materials, Biology, Multiscale Data Analysis and Examples from Complex Physiological Systems,” IEEE ICMA Takamatsu, Japan, pp. 1360-1365, 2017.

- [24] I. Ignatiades, “Redefinition of cell size classification of phytoplankton – a potential tool for improving the quality and assurance of data interpretation,” National Center of Scientific Research “Demokritos” Institute of Biology, 2016.

- [25] A. J. Smits and T. T. Lim, “Flow Visualization techniques and examples,” 2nd Edition, Imperial College Press, 2012.

- [26] C. T. Lim, E. H. Zhou, and S. T. Quek, “Mechanical models for living cells – a review,” J. of Biomechanics, Vol.39, No.2, pp. 195-216, 2006.

- [27] Y. Tanabe, J. C. Pelletier, C. Kanamori, and H. Aoyama, “Micro manipulation by micro flows,” Automation 2015 Int. Conf., E-005(CD-ROM), 2015.

- [28] J. Kestin, H. E. Khalifa, and R. J. Correia, “Tables of the Dynamic and Kinematic Viscosity of Aqueous NaCl Solutions in the Temperature Range 20-150oC and the Pressure Range 0.1-35 MPa,” J. Phys Chem., Vol.10, No.1, 1981.

- [29] V. Guicheret, “Mecanique des fluides,” 2nd year Fluid mechanics textbook, Ecole Nationale Superieure de Mecanique et des Microtechniques, Besançon, 2012.

- [30] D. S. Goodsell, “The Machinery of Life,” Second edition, Springer Editions, pp. 45-50, 2018.

- [31] A. Hirai, “Fine Structure of the Egg Membranes in Four Species of Pleuronectinae,” Japan. J. Ichthyol., Vol.40, No.2, pp. 227-235, 1993.

- [32] A. Ichikawa, et al., “On-chip enucleation of an oocyte by untethered microrobots,” J. Micromech. Microeng., Vol.24, No.9, 095004, 2014.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.