Paper:

Advanced Musical Saw Manipulation by an Industrial Cooperative Humanoid Robot with Passive Sound Feedback

Hiroaki Hanai, Atsuyuki Miura, Toshiki Hirogaki, and Eiichi Aoyama

Doshisha University

1-3 Tataramiyakodani, Kyotanabe, Kyoto 610-0394, Japan

In recent years, collaborative robots able to work together with humans have become widespread in production sites and factory automation fields. In this context, the goal is to provide a production site where cooperative robots can share various types of tools with humans. However, we have not yet reached the point where collaborative robots and humans can share tools for advanced skills. Therefore, it is very important to investigate how a collaborative robot can control advanced tools requiring human skills and the processes for realizing such control. Musical instruments are some of the most difficult tools to handle. It is important to focus on musical instruments because they allow us to evaluate the robot’s manipulation not only by evaluating its movements, but also by evaluating the resultant sound. In this study, we consider a flexible and large deformable musical saw as an unknown and advanced tool difficult for humans to manipulate. In a previous report, a support method for imitating a human was adopted and provided manipulation control based on striking sound feedback using a cooperative humanoid robot. In the present paper, the support method is improved at the tip of the musical saw to realize an advanced wrist motion. In addition, we discuss skillful manipulations based on striking sound feedback control while considering the positions and postures between the collaborative humanoid robot and musical saw.

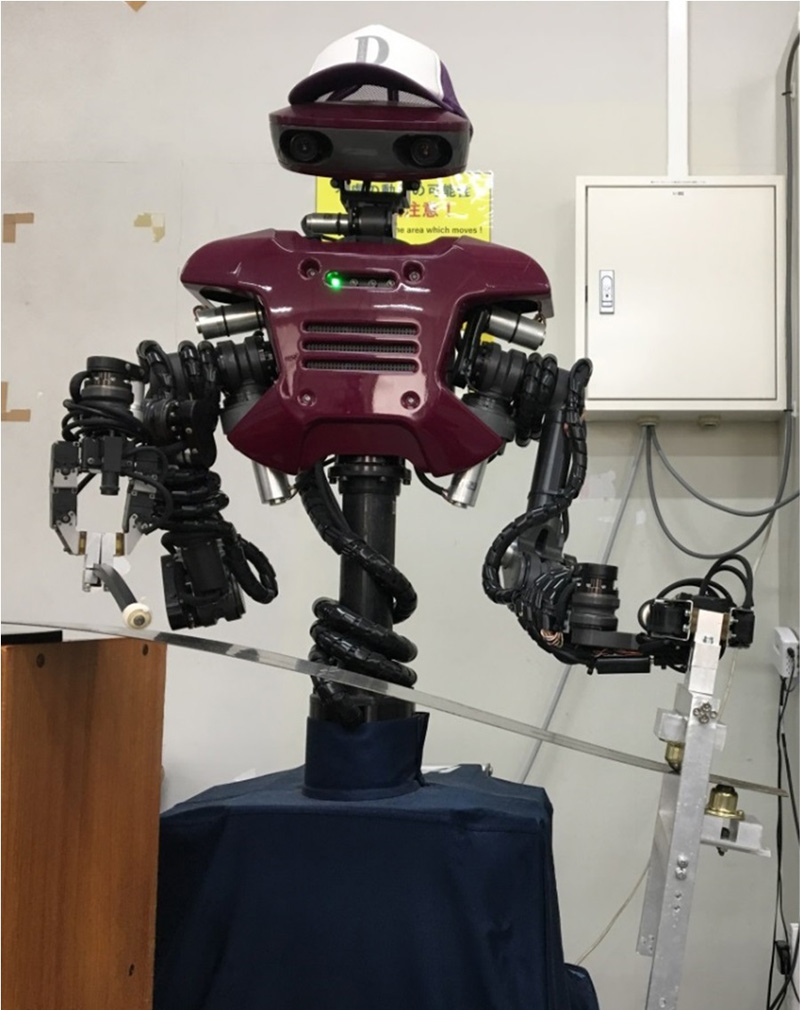

A humanoid robot manipulating a musical saw

- [1] S. K. L. Andersson, A. Granlund, J. Bruch, and M. Hedelind, “Experienced Challenges When Implementing Collaborative Robot Applications in Assembly Operations,” Int. J. Automation Technol., Vol.15, No.5, pp. 678-688, 2021. https://doi.org/10.20965/ijat.2021.p0678

- [2] K. Harada and W. Wan, “On Next Generation Technologies for Industrial Robots,” J. of the Robotics Society of Japan, Vol.37, No.10, pp. 915-918, 2019 (in Japanese). https://doi.org/10.7210/jrsj.37.915

- [3] S. Takagi, “Toyota Partner Robots,” J. of the Robotics Society of Japan, Vol.24, No.2, pp. 208-210, 2006 (in Japanese). https://doi.org/10.7210/jrsj.24.208

- [4] T. Hirogaki, E. Aoyama, Y. Sugiura, and A. Kobayashi, “Investigation of Hammering Task and Application Based on its Hit Sound Feedback Motion with an Industrial Humanoid Robot,” Trans. of the JSME, Vol.83, No.855, Article No.17-00132, 2017 (in Japanese). https://doi.org/10.1299/transjsme.17-00132

- [5] H. Hanai, A. Miura, A. Mishima, T. Hirogaki, and E. Aoyama, “Study on Musical Saw Bowing Motion with an Industrial Cooperative Humanoid Robot,” J. of the Japan Society for Precision Engineering, Vol.88, No.10, pp. 773-780, 2022 (in Japanese). https://doi.org/10.2493/jjspe.88.773

- [6] H. Hanai, A. Mishima, A. Miura, T. Hirogaki, and E. Aoyama, “Realization of Skillful Musical Saw Bowing by Industrial Collaborative Humanoid Robot,” Advances in Science, Technology and Engineering Systems J., Vol.7, No.5, pp. 1-9, 2022. https://doi.org/10.25046/aj070501

- [7] J. Kaneko, N. Hosoya, and K. Furuya, “Minimization of Vibration and Sound Radiation of Thin Plate Structures Based on Musical Saw Mechanism,” The Proc. of the Dynamics & Design Conf. 2010, Article No.111, 2010 (in Japanese). https://doi.org/10.1299/jsmedmc.2010._111-1_

- [8] J. Lenard and J. E. Graebner, “Scratch My Back: A Pictoral History of the Musical Saw and How to Play it,” Kaleidoscope Press, 1989.

- [9] A. Mishima, Y. Fuke, A. Miura, T. Hirogaki, and E. Aoyama, “Playing a Musical Saw with a Humanoid Robot: Investigation for Industrial Automation,” Proc. of the ASME 2019 Int. Design Engineering Technical Conf. and Computers and Information in Engineering Conf., Vol.5A, 2019. https://doi.org/10.1115/DETC2019-97731

- [10] N. H. Fletcher, T. D. Rossing, K. Kishi, H. Kubota, and S. Yoshikawa, “Musical Instrument Physics,” pp. 79-86, 272-277, and 665-666, Maruzen Publishing, 2012 (in Japanese).

- [11] A. Vick, D. Surdilovic, and J. Krüger, “Safe Physical Human-Robot Interaction with Industrial Dual-Arm Robots,” 9th Int. Workshop on Robot Motion and Control, pp. 264-269, 2013. https://doi.org/10.1109/RoMoCo.2013.6614619

- [12] K. D. Marshall, “Modal Analysis of a Violin,” The J. of the Acoustical Society of America, Vol.77, No.2, pp. 695-709, 1985. https://doi.org/10.1121/1.392338

- [13] T. Hirogaki, E. Aoyama, Y. Fuke, A. Mishima, and A. Miura, “Investigation of Tuning Control for Musical Saw Based on Hit Sound Feedback Motion with an Industrial Humanod Robot,” Trans. of the JSME, Vol.87, No.898, Article No.20-00293, 2021 (in Japanese). https://doi.org/10.1299/transjsme.20-00293

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.