Paper:

Fully Automated Bead Art Assembly for Smart Manufacturing Using Dynamic Compensation Approach

Kenichi Murakami*1, Shouren Huang*2, Masatoshi Ishikawa*2,*3, and Yuji Yamakawa*4

*1Institute of Industrial Science, The University of Tokyo

4-6-1 Komaba, Meguro-ku, Tokyo 153-8505, Japan

*2Data Science Research Division, Information Technology Center, The University of Tokyo

7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan

*3Tokyo University of Science

1-3 Kagurazaka, Shinjuku-ku, Tokyo 162-8601, Japan

*4Interfaculty Initiative in Information Studies, The University of Tokyo

4-6-1 Komaba, Meguro-ku, Tokyo 153-8505, Japan

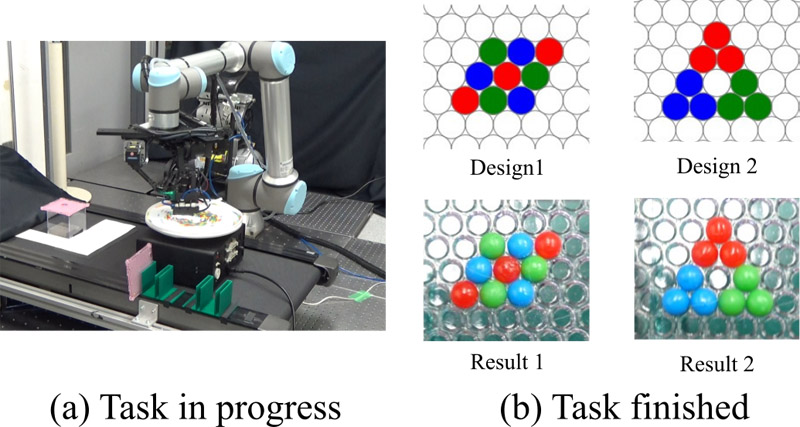

In this study, we demonstrate the implementation of make-to-order bead art assembly without human intervention using dynamic compensation approach to achieve accurate real-time positioning and long-term adaptation for robotic automation in smart manufacturing. In the proposed framework, an industrial robot was designed to perform coarse global motion to implement low-bandwidth adaptation. Simultaneously, fine local motion to tackle real-time online uncertainties was achieved using an add-on robotic module to implement accurate positioning. The effectiveness of the proposed method was verified through experimental evaluations.

Automated assembly of user-designed bead art by robots

- [1] Y. Domae, “Recent Trends in the Research of Industrial Robots and Future Outlook,” J. Robot. Mechatron., Vol.31, No.1, pp. 57-62, 2019.

- [2] N. Asakawa and Y. Takeuchi, “Teachingless Spray-Painting of Sculptured Surface by an Industrial Robot,” Proc. of Int. Conf. on Robotics and Automation, pp. 1875-1879, 1997.

- [3] H. Chen, N. Xi, S. Kamran, Y. Chen, and J. Dahl, “Development of automated chopper gun trajectory planning,” Industrial Robot: An Int. J., Vol.31, No.3, pp. 297-307, 2004.

- [4] Y. Maeda and T. Nakamura, “View-based teaching/playback for robotic manipulation,” ROBOMECH J., Vol.2, Article No.2, 2015.

- [5] K. Brink, M. Olsson, and G. Bolmsjö, “Increased Autonomy in Industrial Robotic Systems: A Framework,” J. of Intelligent and Robotic Systems, Vol.19, pp. 357-373, 1997.

- [6] R. Johansson, A. Robertsson, K. Nilsson, P. Cederberg, M. Olsson, T. Olsson, and G. Bolmsjö, “Sensor integration in task-level programming and industrial robotic task execution control,” Industrial Robot: An Int. J., Vol.31, No.3, pp. 284-296, 2004.

- [7] N. Mendes, P. Neto, J. N. Pires, and A. Loureiro, “An optimal fuzzy-PI force/motion controller to increase industrial robot autonomy,” Int. J. Adv. Manuf. Technol., Vol.68, pp. 435-441, 2013.

- [8] B. Mei, W. Zhu, H. Dong, and Y. Ke, “Coordination error control for accurate positioning in movable robotic drilling,” Assembly Automation, Vol.35, No.4, pp. 329-340, 2015.

- [9] B. Shirinzadeh, P. L. Teoh, Y. Tian, M. M. Dalvand, Y. Zhong, and H. C. Liaw, “Laser interferometry-based guidance methodology for high precision positioning of mechanisms and robots,” Robotics and Computer-Integrated Manufacturing, Vol.26, pp. 74-82, 2010.

- [10] C. Cheah, M. Hirano, S. Kawamura, and S. Arimoto, “Approximate jacobian control for robots with uncertain kinematics and dynamics,” IEEE Trans. Robot. Autom., Vol.19, pp. 692-702, 2003.

- [11] H. Wang, Y. Liu, and D. Zhou, “Adaptive visual servoing using point and line features with an uncalibrated eye-in-hand camera,” IEEE Trans. Robot., Vol.24, pp. 843-856, 2008.

- [12] A. Bauchspiess, S. Alfaro, and L. Dobrzanski, “Predictive sensor guided robotic manipulators in automated welding cells,” J. Mater. Process. Technol., Vol.109, pp. 13-19, 2001.

- [13] F. Lange and G. Hirzinger, “Predictive visual tracking of lines by industrial robots,” Int. J. Rob. Res., Vol.22, pp. 889-903, 2003.

- [14] S. Levine, P. Pastor, A. Krizhevsky, J. Ibarz, and D. Quillen, “Learning hand-eye coordination for robotic grasping with deep learning and large-scale data collection,” Int. J. Rob. Res., Vol.37, pp. 421-436, 2018.

- [15] O. Khatib, “A Unified Approach for Motion and Force Control of Robot Manipulators: The Operational Space Formulation,” IEEE Trans. Robot. Autom., Vol.3, No.1, pp. 43-53, 1987.

- [16] E. Zergeroglu, D. D. Dawson, I. W. Walker, and P. Setlur, “Nonlinear Tracking Control of Kinematically Redundant Robot Manipulators,” IEEE ASME Trans. Mechatron., Vol.9, No.1, pp. 129-132, 2004.

- [17] H. Sadeghian, L. Villani, M. Keshmiri, and B. Siciliano, “Task-Space Control of Robot Manipulators With Null-Space Compliance,” IEEE Trans. Robot., Vol.30, No.2, pp. 493-506, 2014.

- [18] J. S. Gua and C. W. de Silva, “Development and implementation of a real-time open-architecture control system for industrial robot systems,” Engineering Applications of Artificial Intelligence, Vol.17, pp. 469-483, 2004.

- [19] A. Sharon, N. Hogan, and E. Hardt, “The macro/micro manipulator: an improved architecture for robot control,” Robot Comput-Integr. Manuf., Vol.10, pp. 209-222, 1993.

- [20] A. Omari, A. Ming, S. Nakamura, C. Kanamori, and M. Kajitani, “Development of a High-precision Mounting Robot with Fine Motion Mechanism (3rd Report) – Positioning Experiment of SCARA Robot with Fine Mechanism,” The Japan Society for Precision Engineering, Vol.67, pp. 1101-1107, 2001.

- [21] M. Freundt, C. Brecher, and C. Wenzel, “Hybrid universal handling systems for micro component assembly,” Microsyst. Technol., Vol.14, pp. 1855-1860, 2008.

- [22] J. Sulzer and I. Kovac, “Enhancement of positioning accuracy of industrial robots with a reconfigurable fine-positioning module,” Precision Engineering, Vol.34, pp. 201-207, 2010.

- [23] U. Schneider, B. Olofsson, O. Sornmo, M. Drust, A. Robertsson, M. Hagele, and R. Johansson, “Integrated Approach to Robotic Machining with Macro/Micro-actuation,” Robot. Comput.-Integr. Manuf., Vol.30, pp. 636-647, 2014.

- [24] S. Huang, N. Bergström, Y. Yamakawa, T. Senoo, and M. Ishikawa, “Robotic Contour Tracing with High-Speed Vision and Force-Torque Sensing based on Dynamic Compensation Scheme,” IFAC-PapersOnLine, Vol.50, No.1, pp. 4616-4622, 2017.

- [25] S. Huang, K. Shinya, N. Bergström, Y. Yamakawa, T. Yamazaki, and M. Ishikawa, “Dynamic compensation robot with a new high-speed vision system for flexible manufacturing,” Int. J. Adv. Manuf. Technol., Vol.95, pp. 4523-4533, 2018.

- [26] S. Huang, M. Ishikawa, and Y. Yamakawa, “A coarse-to-fine framework for accurate positioning under uncertainties – from autonomous robot to human-robot system,” Int. J. Adv. Manuf. Technol., Vol.108, pp. 2929-2944, 2020.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.