Letter:

In-Situ X-Ray Analyses of Structural Change During Drawing and Shrinking of Linear Low-Density Polyethylene Film

Hiroaki Yoshizawa*, Ayaka Takazawa*, Masaki Kakiage*, Takeshi Yamanobe*, Naoki Hayashi**, Maki Hiraoka**, Hiroyasu Masunaga***, Kouki Aoyama***, and Hiroki Uehara*

*Division of Molecular Science, Faculty of Science and Technology, Gunma University

1-5-1 Tenjin-cho, Kiryu, Gunma 376-8515, Japan

**Panasonic Corporation

3-1-1 Yagumonakamachi, Moriguchi, Osaka 570-8501, Japan

***Japan Synchrotron Radiation Research Institute (JASRI) / SPring-8

1-1-1 Kouto, Sayo-cho, Sayo-gun, Hyogo 679-5198, Japan

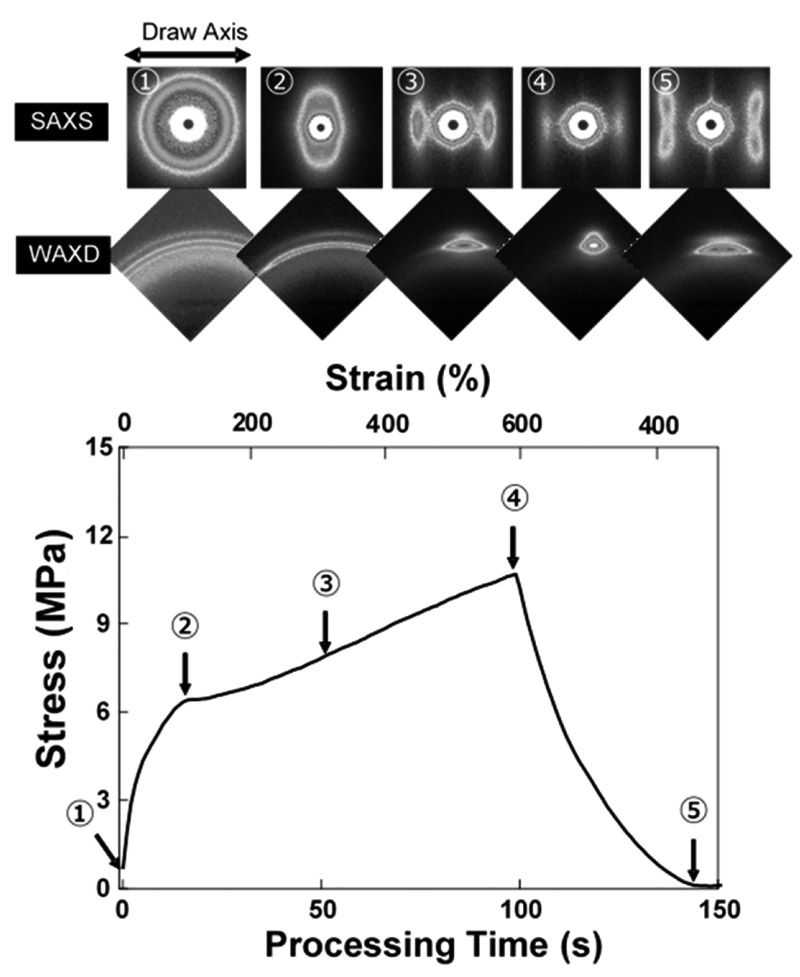

Structural changes during the drawing and shrinking of linear low-density polyethylene (LLDPE) film are analyzed through in-situ X-ray measurements. A synchrotron radiation source enables simultaneous analyses combining small-angle X-ray scattering (SAXS) and wide-angle X-ray diffraction (WAXD). During drawing, the original unoriented SAXS and WAXD patterns transformed into line and spot patterns, indicating the orientation of both lamellar stacking and the molecular axis along the drawing direction. During the subsequent shrinking these patterns are retained, suggesting the tilted lamellar and molecular chains. A possible model for structural changes indicates that tie molecules between lamellae effectively transmit drawing and shrinking stresses, which contributes to desirable actuation properties.

Stress profile and in-situ X-ray patterns recorded during drawing and shrinking for LLDPE film

- [1] K. Takashima, T. Noritsugu, J. Rossiter, S. Guo, and T. Mukai, “Curved Type Pneumatic Artificial Rubber Muscle Using Shape-Memory Polymer,” J. Robot. Mechatron., Vol.24, No.3, pp. 472-479, 2012.

- [2] K. Takashima, D. Iwamoto, S. Oshiro, T. Noritsugu, and T. Mukai, “Characteristics of Pneumatic Artificial Rubber Muscle Using Two Shape-Memory Polymer Sheets,” J. Robot. Mechatron., Vol.33, No.3, pp. 653-664, 2021.

- [3] M. Hiraoka, K. Nakamura, H. Arase, K. Asai, Y. Kaneko, S. W. John, K. Tagashira, and A. Omote, “Power-Efficient Low-Temperature Woven Coiled Fibre Actuator for Wearable Applications,” Sci. Rep., Vol.6, 36358, 2016.

- [4] H. Yoshizawa, A. Takazawa, M. Kakiage, T. Yamanobe, N. Hayashi, M. Hiraoka, H. Masunaga, K. Aoyama, and H. Uehara, “Actuation Mechanism of Drawn Polyethylene Evaluated by Structural Change During Cyclic Stretching/shrinking,” Sens. Actuators A: Phys., Vol.323, 112634, 2021.

- [5] S. Kato, H. Tanaka, T. Yamanobe, and H. Uehara, “In Situ Analysis of Melt-Drawing Behavior of Ultrahigh Molecular Weight Polyethylene Films with Different Molecular Weights: Roles of Entanglements on Oriented Crystallization,” J. Phys. Chem. B, Vol.119, No.15, pp. 5062-5070, 2015.

- [6] S. Fujii, S. Nishitsuji, M. Takanaka, and H. Hashegawa, “Study on Hierarchical Structure of Polyethylene by Using USAXS, SAXS and WAXS,” Kobunshi Ronbunshu, Vol.66, No.12, pp. 612-618, 2009.

- [7] Y. T. Liu, L. X. Yin, H. R. Zhao, G. K. Song, F. M. Tang, L. L.Wang, H. L. Shao, and Y. P. Zhang, “Lamellar and Fibrillar Structure Evolution of Poly(ethylene Terephthalate) Fiber in Thermal Annealing,” Polymer, Vol.105, pp. 157-166, 2016.

- [8] Y. Ono, M. Kakiage, T. Yamanobe, Y. Yukawa, Y. Higuchi, H. Kamiya, K. Arai, and H. Uehara, “Structural and Property Changes During Uniaxial Drawing of Ethylene-Tetrafluoroethylene Copolymer Films as Analyzed by In-Situ X-Ray Measurements,” Polymer, Vol.52, No.4, pp. 1172-1179, 2011.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.