Letter:

Development of a PVC Gel Actuator with a Particulate Structure

Aya Suzuki and Minoru Hashimoto

Open Venture Innovation Center (OVIC), Shinshu University

2-16-24 Fumiiri, Ueda, Nagano 386-0017, Japan

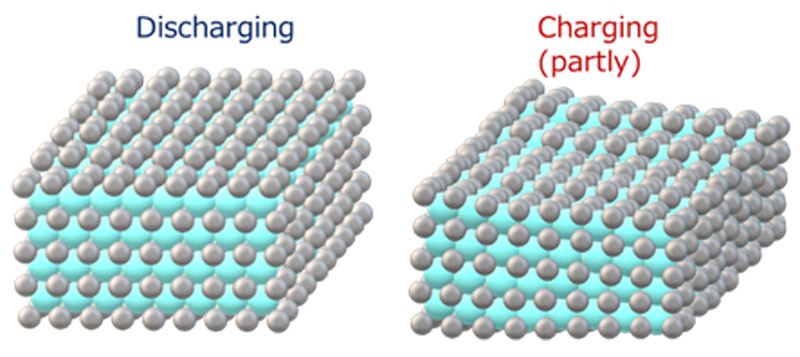

Actuators are usually driven in a uniaxial direction, which limits their ability to be driven with multiple degrees of freedom. In this study, we propose an actuator that is not limited to a uniaxial direction. We developed a polyvinyl chloride gel actuator with a particulate structure. The actuator can change its surface shape by displacing each particle in the structure. As the first step in this experiment, each particle was displaced independently, by applying a voltage to the anode to change the actuator’s surface into an uneven shape.

Illustration of surface deformation in the particulate structure

- [1] Md. Z. Uddin, M. Watanabe, H. Shirai, and T. Hirai, “Creeping and novel huge bending of plasticized PVC,” J. Robot. Mechatron., Vol.14, No.2, pp. 118-123, 2002.

- [2] Y. Li, Y. Tsuchiya, A. Suzuki, Y. Shirai, and M. Hashimoto, “Influence of the Number of Stacked Layers on the Performance of PVC Gel Actuators,” IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics, pp. 94-99, 2014.

- [3] Y. Li and M. Hashimoto, “PVC gel based artificial muscles: Characterizations and actuation modular constructions,” Sensors and Actuators A: Physical, Vol.233, pp. 246-258, 2015.

- [4] Y. Li and M. Hashimoto, “A Novel Sheet Actuator using Plasticized PVC Gel and Flexible Electrodes,” Proc. of SPIE10163, Electroactive Polymer Actuators and Devices (EAPAD), 2017.

- [5] A. Furuse and M. Hashimoto, “Development of novel textile and yarn actuators using plasticized PVC gel,” Proc. of SPIE10163, Electroactive Polymer Actuators and Devices (EAPAD), 2017.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.