Paper:

Raw Material Composition Control Method for Cement Based on Semi-Tensor Product

Ping Jiang, Hongliang Yu, Shi Li, and Xiaohong Wang

School of Electronic and Engineering, University of Jinan

No.336 West Road of Nan Xinzhuang, Jinan, Shandong 250022, China

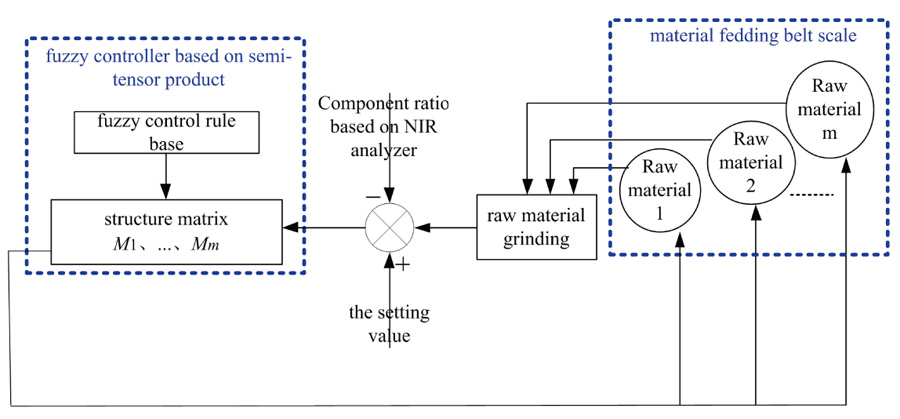

The cement production process can be summarized into two grinding processes and one burning process. The two grinding processes refer to raw material and cement grinding. The burning process is the clinker calcination of a raw material. Such processes are complicated and continuous. The quality of the previous stage has an important influence on the latter. The raw meal preparation is the most important part in cement production. The composition of raw meal determines whether the three rate values are appropriate, ensuring stable production on the cement production line.

The raw material composition control method for cement

- [1] L. K. Woolery and J. Grzymala-Busse, “Machine Learning for An Expert System to Predict Preterm Birth Risk,” J. of the American Medical Informatics Association, Vol.1, No.6, pp. 439-446, 1994.

- [2] P. Salvaneschi, M. Cedei, and M. Lazzari, “Applying AI to Structural Safety Monitoring and Evaluation,” IEEE Expert, Vol.11, No.4, pp. 24-34, 2014.

- [3] M. Lazzari and P. Salvaneschi, “Embedding A Geographic Information System in A Decision Support System for Landslide Hazard Monitoring,” Natural Hazards, Vol.20, No.2-3, pp. 185-195, 1999.

- [4] N. Arman, “Fault Detection in Dynamic Rule Bases using Spanning Trees and Disjoint Sets,” Int. Arab J. of Information Technology, Vol.4, No.1, pp. 67-72, 2007.

- [5] G. Feng, “A Survey on Analysis and Design of Model-Based Fuzzy Control Systems,” IEEE Tran. on Fuzzy Systems, Vol.14, No.5, pp. 676-697, 2006.

- [6] G. Feng, “Analysis and Synthesis of Fuzzy Control Systems: A Model-based Approach,” CRC Press, 2017.

- [7] D. Z. Cheng, H. S. Qi, and Z. Q. Li, “Analysis and Control of Boolean Networks: A Semi-tensor Product Approach,” Springer, 2011.

- [8] D. Z. Cheng, J. E. Feng, and H. Lv, “Solving Fuzzy Relational Equations via Semitensor Product,” IEEE Tran. on Fuzzy Systems, Vol.20, No.2, pp. 390-396, 2012.

- [9] J. E. Feng, H. Lv, and D. Z. Cheng, “Multiple Fuzzy Relation and Its Application to Coupled Fuzzy Control,” Asian J. of Control, Vol.15, No.5, pp. 1313-1324, 2013.

- [10] H. T. Li and Y. Z. Wang, “Boolean Derivative Calculation with Application to Fault Detection of Combinational Circuits via the Semi-tensor Product Method,” Automatica, Vol.48, No.4, pp. 688-693, 2012.

- [11] H. T. Li, Y. Z. Wang, and Z. B. Liu, “Existence and Mumber of Fixed Points of Boolean Transformations via the Semi-tensor Product Method,” Applied Mathematics Letters, Vol.25, No.8, pp. 1142-1147, 2012.

- [12] Z. B. Liu and Y. Z. Wang, “Disturbance Decoupling of Mix-valued Logical Networks via the Semi-tensor Product Method,” Automatica, Vol.48, No.8, pp. 1839-1844, 2012.

- [13] Y. Z. Wang, C. H. Zhang, and Z. B. Liu, “A Matrix Approach to Graph Maximum Stable Set and Coloring Problems with Application to Multi-agent Systems,” Automatica, Vol.48, No.7, pp. 1227-1236, 2012.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.