Development Report:

Study on the Influence of Temperature of Extruder Head on the Strength of the FDM 3D Printing Model

Hiroki Endo and Takashi Umeno

Department of Mechanical Engineering, Kyushu Sangyo University

2-3-1 Matsukadai, Higashi-ku, Fukuoka 813-8503, Japan

This paper reported the tensile strength of the difference of modeling condition on the FDM (Fused Deposition Modeling) 3D printer. The FDM 3D printer is rapidly spread with the end of patent protection in 2009. The FDM models mainly use the prototyping part and art, because that models have low strength. This time we paid attention to that actual models weight is lighter than designing models weight to conduct study on strength. And we investigated the cause of the phenomenon of decrease of polymer extrusion by replacing with the injection molding method. The tensile test proved that the strength of model can be improved by the kind of extruder head. This paper reported influence of the cooling in the supply part of extruder head and temperature of the polymer on the strength of FDM 3D models.

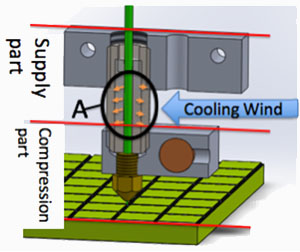

Cross session of the extruder head

- [1] R. Angle, A. Q. Asif, Q. Yasir, and R. Rehman, “Rheological Properties of ABS at Low Shear Rates: Effects of Phase Heterogeneity,” Malaysian Polymer J., Vol.4, No.2, pp. 29-36, 2009.

- [2] S. Hwang, E. I. Reyes, K.-s. Moon, R. C. Rumpf, and N. S. Kim, “Thermo-mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process,” J. of Electronic Materials, Vol.44, No.3, 2015.

- [3] L. Novakova-Marcincinova and J. Novak-Marcincin, “Verification of mechanical properties of ABS materials used in FDM rapid prototyping,” Proc. in Manufacturing Systems, Vol.8, Issue 2, 2013.

- [4] A. R. T. Perez, D. A. Roberson, and R. B. Wicker, “Fracture surface analysis of 3D-printed tensile specimens of novel ABS-based materials,” J. of Failure Analysis and Prevention, Vol.14, Issue 3, pp. 343-353, 2014.

- [5] Y. Bai, N. Li, Y. Liu, and M. Run, “Morphology and mechanical properties of poly(trimethylene terephthalate)/ maleinized Acrylonitrile-Butadiene-Styrene blends,” Asian J. of Chemistry, Vol.27, Issue 7, pp. 2548-2554, 2015.

- [6] M. S. Krupashankara, “Mathematical modeling and experimental evaluation of the tensile properties of multiwalled carbon nanotubes filled Acrylonitrile Butadiene Styrene composites,” i-Manager’s J. on Material Science, Vol.3, Issue 1, pp. 23-30, 2015.

- [7] M. S. Hossain, D. Espalin, M. Perez, and R. Wicker, “Improving Tensile Mechanical Properties of FDM-Manufactured Specimens via Modifying Build Parameters,” 24th Int. SFF Symposium – An Additive Manufacturing Conf., pp. 380-392, 2013.

- [8] A. Bagsik, “Mechanical properties of fused deposition modeling parts,” ANTEC2011, 9085, 2001.

- [9] H. Eiliat and J. Urbanic, “Experimental Evaluation of Light-weighting Design Options for the Fused Deposition Modelling Process,” The 2015 Industrial and Systems Engineering Research Conf., 2015.

- [10] I. Durgun and R. Ertan, “Experimental investigation of FDM process for improvement of mechanical properties and production cost,” Rapid Prototyping J., Vol.20, Issue 3, pp. 228-235, 2014.

- [11] K. Arakaki, T. Hamabe, and T. Tanaka, “Study of new hybrid material of polymer of using 3D print modeling filament,” Applied Materials Engineering Laboratory, Doshisha University, 2014.

- [12] K. Arakawa, “Dynamic sliding friction and similarity with Stokes’ law,” Tribology Int., Vol.94, pp. 77-81, 2016.

- [13] T. Yasuda, “Test method and evaluation result of each dynamic characteristic of plastic material,” Plastic, Vol.52, No.9, pp. 96-103, 2001.

- [14] The Society of Polymer Science Japan, “ABS polymer,” Maruzen Yushindo Co. Ltd., 1970.

- [15] H. Hamada and Y. Ota, “Why-Why technology of resin finishing,” Kogyo Chosakai Publishing Co., Ltd., 2004.

- [16] Y. Hagiwara, A. Misawa, and H. Suzuki, “Well understood of mechanics of materials,” Ohmsha Ltd., 1996.

- [17] Y. Li and H. Shimizu, “Improvement in Toughness of Poly (L- lactic Acid) (PLLA) through Reactive Blending with Acrylonitrile-Butadiene-Styrene Copolymer (ABS): Morphology and Properties,” European Polymer J., Vol.45, pp. 738-746, 2009.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.