Review:

Multi-Intelligent Excavator Collaboration Systems: An Overview

Bin Zhang*,**

, Jiayang Hu*,**

, Jiayang Hu*,**

, Teng Yang*, and Haocen Hong**

, Teng Yang*, and Haocen Hong**

*School of Mechanical Engineering, Zhejiang University

No.866 Yuhangtang Road, Hangzhou, Zhejiang 310030, China

**Institute of Advanced Machines Zhejiang University

No.505 Xingguo Road, Hangzhou, Zhejiang 311106, China

The advancement in automation technology for excavators signifies a shift from individual excavation tasks to collaborative multi-machine operations, with the aim of enhancing efficiency and safety in extensive operations. This study presents a concise overview of multi-intelligent excavator collaboration systems (MECS), introducing a framework that includes networked communication, task analysis, and motion planning. Networked communication is foundational, bolstered by the widespread use of Ethernet and the industrialization of 5G technology. Task analysis, which is the core of system, is bifurcated into single-agent intelligence and multi-machine collaboration, considering the task efficiency and collaborative completeness in complex environments. Motion planning, inherently linked to task analysis, is divided into operational and mobility aspects. Finally, this paper concludes by summarizing and projecting key technologies within the framework of collaborative systems.

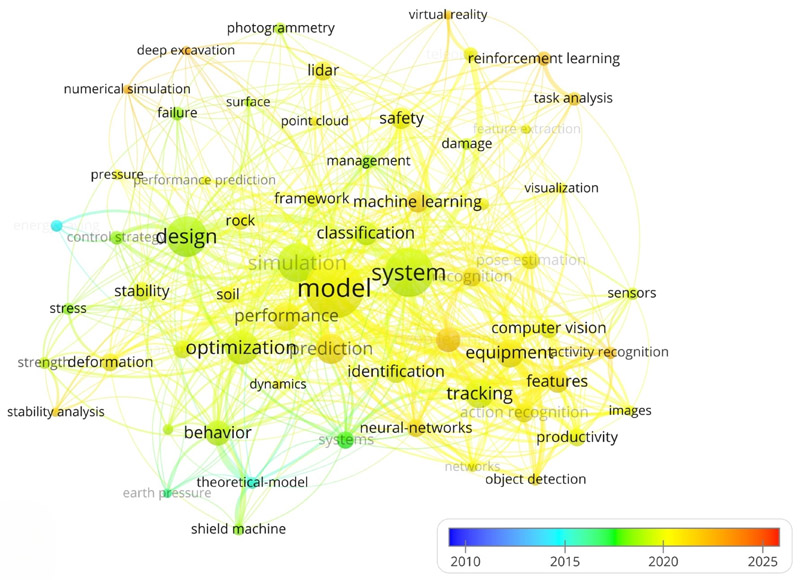

MECS keyword mapping

- [1] B. Zhang, J. Hu, T. Yang, Y. Chen, and H. Hong, “Enhanced motion estimation for autonomous excavation: Accelerated semantic segmentation and ORB features for unstructured environments,” IEEE Access, Vol.12, pp. 157516-157530, 2024. https://doi.org/10.1109/ACCESS.2024.3485901

- [2] T. Yang et al., “Motion control for earth excavation robot based on force pre-load and cross-coupling compensation,” Automation in Construction, Vol.141, Article No.104402, 2022. https://doi.org/10.1016/j.autcon.2022.104402

- [3] S. H. Wen, “Design of remote control and monitoring system for electric excavator based on wireless communication,” Master’s thesis, Huaqiao University, 2020 (in Chinese). https://doi.org/10.27155/d.cnki.ghqiu.2020.000918

- [4] Editorial Department of Construction Machinery Technology & Management, “The global 1st 5G remote controlled excavator launched by Sany and Huawei,” Construction Machinery Technology & Management, Vol.32, No.7, pp. 33-34, 2019 (in Chinese). https://doi.org/10.13824/j.cnki.cmtm.2019.07.010

- [5] H. Yan, “All-star lineup becomes the focus of the show Shandong Lingong shines at Bauma Shanghai 2020,” Construction Machinery Today, Vol.2020, No.6, pp. 58-59, 2020 (in Chinese).

- [6] X. Wang, F. H. Zhang, B. Yi, J. Yu, and Z. M. Yuan, “Excavator and method of cooperative operation, processor, vehicle-mounted terminal, and control terminal,” CN Patent CN115324147A, 2022.

- [7] Y. Miao, “‘Digital drive, green pioneer’ XCMG’s wonderful appearance at BICES 2023,” Construction Enterprise Management, Vol.2023, No.10, p. 120, 2023 (in Chinese).

- [8] S.-K. Kim and J. S. Russell, “Framework for an intelligent earthwork system: Part I. System architecture,” Automation in Construction, Vol.12, No.1, pp. 1-13, 2003. https://doi.org/10.1016/S0926-5805(02)00034-1

- [9] S.-K. Kim and J. S. Russell, “Framework for an intelligent earthwork system: Part II. Task identification/scheduling and resource allocation methodology,” Automation in Construction, Vol.12, No.1, pp. 15-27, 2003. https://doi.org/10.1016/S0926-5805(02)00033-X

- [10] J. Kim and J. Seo, “Task planner for autonomous excavator considering work environment,” Proc. of the 28th ISARC, pp. 770-771, 2011. https://doi.org/10.22260/ISARC2011/0143

- [11] J. Li, Z. Cai, M. Li, W. Huang, and Y. Zhang, “Dynamic task allocation for heterogeneous multi-robot system under communication constraints,” IEEE 6th Information Technology, Networking, Electronic and Automation Control Conf., pp. 457-463, 2023. https://doi.org/10.1109/ITNEC56291.2023.10082491

- [12] D. Sun et al., “Creation of one excavator as an obstacle in C-space for collision avoidance during remote control of the two excavators using pose sensors,” Remote Sensing, Vol.12, No.7, Article No.1122, 2020. https://doi.org/10.3390/rs12071122

- [13] X. Ge, F. Yang, and Q.-L. Han, “Distributed networked control systems: A brief overview,” Information Sciences, Vol.380, pp. 117-131, 2017. https://doi.org/10.1016/j.ins.2015.07.047

- [14] P. Giselsson, M. D. Doan, T. Keviczky, B. D. Schutter, and A. Rantzer, “Accelerated gradient methods and dual decomposition in distributed model predictive control,” Automatica, Vol.49, No.3, pp. 829-833, 2013. https://doi.org/10.1016/j.automatica.2013.01.009

- [15] G. Guo, J. Kang, R. Li, and G. Yang, “Distributed model reference adaptive optimization of disturbed multiagent systems with intermittent communications,” IEEE Trans. on Cybernetics, Vol.52, No.6, pp. 5464-5473, 2022. https://doi.org/10.1109/TCYB.2020.3032429

- [16] Y. Xu, Z.-G. Wu, and Y.-J. Pan, “Observer-based dynamic event-triggered adaptive control of distributed networked systems with application to ground vehicles,” IEEE Trans. on Industrial Electronics, Vol.70, No.4, pp. 4148-4157, 2023. https://doi.org/10.1109/TIE.2022.3176242

- [17] D. H. Gao, “Compensation of the delay & packet dropouts in CAN network and its application in hybrid excavators,” Ph.D. thesis, Zhejiang University, 2016 (in Chinese).

- [18] K. Cheng, X. Wang, and Y. Wang, “Research of hydraulic excavators distributed monitoring-control system based on CAN-bus,” Machine Tool & Hydraulics, Vol.2005, No.8, pp. 154-156+189, 2005.

- [19] Z. Tong et al., “Development of electric construction machinery in China: A review of key technologies and future directions,” J. of Zhejiang University–SCIENCE A, Vol.22, No.4, pp. 245-264, 2021. https://doi.org/10.1631/jzus.A2100006

- [20] Z. Tong et al., “Energy-saving technologies for construction machinery: A review of electro-hydraulic pump-valve coordinated system, J. of Zhejiang University–SCIENCE A, Vol.21, No.5, pp. 331-349, 2020. https://doi.org/10.1631/jzus.A2000094

- [21] Z. Wang, W. Ma, G. Xiong, and Z. Yang, “Survey of CAN field bus for safety critical systems,” Application Research of Computers, Vol.28, No.4, pp. 1216-1220, 2011 (in Chinese). https://doi.org/10.3969/j.issn.1001-3695.2011.04.004

- [22] D. Gao and Q. Wang, “Health monitoring of controller area network in hybrid excavator based on the message response time,” 2014 IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics, pp. 1634-1639, 2014. https://doi.org/10.1109/AIM.2014.6878318

- [23] L. Mi, K. Feng, H. L. Li, and L. F. Shao, “The fault detection and diagnosis system of hydraulic excavator based on PXI interface technology,” Applied Mechanics and Materials, Vols.268-270, pp. 1440-1443, 2012. https://doi.org/10.4028/www.scientific.net/AMM.268-270.1440

- [24] Z. Jun et al., “Design of electronic control system of hydraulic excavator with CAN bus and PID method,” 2010 Int. Conf. on Intelligent System Design and Engineering Application, pp. 570-573, 2010. https://doi.org/10.1109/ISDEA.2010.293

- [25] C. Frese et al., “An autonomous crawler excavator for hazardous environments,” Automatisierungstechnik, Vol.70, No.10, pp. 859-876, 2022. https://doi.org/10.1515/auto-2022-0068

- [26] G. Cena and A. Valenzano, “A protocol for automatic node discovery in CANopen networks,” IEEE Trans. on Industrial Electronics, Vol.50, No.3, pp. 419-430, 2003. https://doi.org/10.1109/TIE.2003.812281

- [27] L. Wang, L. Guo, and Z. Liu, “Design of STM32-based CANopen motion control master in transfer robot,” 3rd Int. Conf. on Instrumentation, Measurement, Computer, Communication and Control, pp. 1609-1612, 2013. https://doi.org/10.1109/IMCCC.2013.357

- [28] Q. H. Zhou, S. Y. Lu, and Q. B. Li, “Study on universal intelligent monitoring system in heavy machinery based on CANopen protocol,” Applied Mechanics and Materials, Vol.552, pp. 166-169, 2014. https://doi.org/10.4028/www.scientific.net/AMM.552.166

- [29] D. Yang, X. Chen, and J. Xiong, “Research on new data network architecture based on double nets sharing to machinery equipment,” China Mechanical Engineering, Vol.25, No.3, pp. 366-371, 2014 (in Chinese). https://doi.org/10.3969/j.issn.1004-132X.2014.03.016

- [30] Z. Huang, X. Jiang, L. Chen, and D. Fan, “Research on safe communication architecture for real-time Ethernet distributed control system,” IEEE Access, Vol.7, pp. 89821-89832, 2019. https://doi.org/10.1109/ACCESS.2019.2926650

- [31] J. A. Kay, R. A. Entzminger, and D. C. Mazur, “Industrial Ethernet—Overview and best practices,” Conf. Record of 2014 Annual Pulp and Paper Industry Technical Conf., pp. 18-27, 2014. https://doi.org/10.1109/PPIC.2014.6871144

- [32] F. P. Wang, X. C. Gao, and B. Jiang, “An excavator communication system,” Patent CN202221003325.1, 2022-08-02, 2022.

- [33] K. Y. Shen, “Design of remote control system and trajectory planning research for small excavator,” Master’s thesis, Taiyuan University of Science and Technology, 2023 (in Chinese). https://doi.org/10.27721/d.cnki.gyzjc.2023.000225

- [34] C. L. Ji, “XCMG’s ‘steel mantis’,” Modern Group, Vol.2023, No.5, p. 13, 2023 (in Chinese).

- [35] J. S. Bao et al., “An unmanned mining truck and unmanned excavator full-process truck and shovel cooperative loading control method,” CN Patent CN117852822A, 2024.

- [36] X. Zhang, P. Zhang, C. Wang, and Z. Zhang, “Automatic inspection system of excavator performance based on vehicle data analysis,” Construction Machinery and Equipment, Vol.53, No.10, pp. 1-5+7, 2022 (in Chinese).

- [37] H. Z. Lin, Z. J. Li, L. Tian, Z. C. Zhang, and Y. C. Zhao, “An excavator and self-driving mine car loading cooperative operation system and method,” CN Patent, CN202211625547.1, 2022.

- [38] A. A. Elezaby, M. Abdelaziz, and S. Cetinkunt, “Operator model for construction equipment,” 2008 IEEE/ASME Int. Conf. on Mechatronic and Embedded Systems and Applications, pp. 582-585, 2008. https://doi.org/10.1109/MESA.2008.4735708

- [39] J. Seo, S. Lee, J. Kim, and S.-K. Kim, “Task planner design for an automated excavation system,” Automation in Construction, Vol.20, No.7, pp. 954-966, 2011. https://doi.org/10.1016/j.autcon.2011.03.013

- [40] Y. Du, M. C. Dorneich, and B. Steward, “Modeling expertise and adaptability in virtual operator models,” Automation in Construction, Vol.90, pp. 223-234, 2018. https://doi.org/10.1016/j.autcon.2018.02.030

- [41] R. Fukui, T. Niho, M. Nakao, and M. Uetake, “Imitation-based control of automated ore excavator to utilize human operator knowledge of bedrock condition estimation and excavating motion selection,” 2015 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 5910-5916, 2015. https://doi.org/10.1109/IROS.2015.7354217

- [42] R. Fukui, T. Niho, M. Nakao, and M. Uetake, “Imitation-based control of automated ore excavator: Improvement of autonomous excavation database quality using clustering and association analysis processes,” Advanced Robotics, Vol.31, No.11, pp. 595-606, 2017. https://doi.org/10.1080/01691864.2017.1297735

- [43] R. Tsuzuki, K. Hara, and D. Usui, “Development of a highly efficient trajectory planning algorithm in backfilling task for autonomous excavators by imitation of experts and numerical optimization,” J. Robot. Mechatron., Vol.36, No.2, pp. 263-272, 2024. https://doi.org/10.20965/jrm.2024.p0263

- [44] D. Janosevic, R. Mitrev, B. Andjelkovic, and P. Petrov, “Quantitative measures for assessment of the hydraulic excavator digging efficiency,” J. of Zhejiang University—SCIENCE A, Vol.13, No.12, pp. 926-942, 2012. https://doi.org/10.1631/jzus.A1100318

- [45] H. Song et al., “A novel data fusion based intelligent identification approach for working cycle stages of hydraulic excavators,” ISA Trans., Vol.148, pp. 78-91, 2024. https://doi.org/10.1016/j.isatra.2024.03.006

- [46] J. Zhao and L. Zhang, “TaskNet: A neural task planner for autonomous excavator,” 2021 IEEE Int. Conf. on Robotics and Automation, pp. 2220-2226, 2021. https://doi.org/10.1109/ICRA48506.2021.9561629

- [47] Q. Guo, Z. Ye, L. Wang, and L. Zhang, “Imitation learning and model integrated excavator trajectory planning,” 2022 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 5737-5743, 2022. https://doi.org/10.1109/IROS47612.2022.9981220

- [48] Q. Lu, Y. Zhu, and L. Zhang, “Excavation reinforcement learning using geometric representation,” IEEE Robotics and Automation Letters, Vol.7, No.2, pp. 4472-4479, 2022. https://doi.org/10.1109/LRA.2022.3150511

- [49] P. Egli, D. Gaschen, S. Kerscher, D. Jud, and M. Hutter, “Soil-adaptive excavation using reinforcement learning,” IEEE Robotics and Automation Letters, Vol.7, No.4, pp. 9778-9785, 2022. https://doi.org/10.1109/LRA.2022.3189834

- [50] T. Osa and M. Aizawa, “Deep reinforcement learning with adversarial training for automated excavation using depth images,” IEEE Access, Vol.10, pp. 4523-4535, 2022. https://doi.org/10.1109/ACCESS.2022.3140781

- [51] T. Osa, N. Osajima, M. Aizawa, and T. Harada, “Learning adaptive policies for autonomous excavation under various soil conditions by adversarial domain sampling,” IEEE Robotics and Automation Letters, Vol.8, No.9, pp. 5536-5543, 2023. https://doi.org/10.1109/LRA.2023.3296933

- [52] K. Arulkumaran, M. P. Deisenroth, M. Brundage, and A. A. Bharath, “Deep reinforcement learning: A brief survey,” IEEE Signal Processing Magazine, Vol.34, No.6, pp. 26-38, 2017. https://doi.org/10.1109/MSP.2017.2743240

- [53] C. Chi et al., “Cooperatively improving data center energy efficiency based on multi-agent deep reinforcement learning,” Energies, Vol.14, No.8, Article No.2071, 2021. https://doi.org/10.3390/en14082071

- [54] C. R. Qi, L. Yi, H. Su, and L. J. Guibas, “PointNet++: Deep hierarchical feature learning on point sets in a metric space,” arXiv:1706.02413, 2017. https://doi.org/10.48550/arXiv.1706.02413

- [55] N. Fung et al., “Coordinating multi-robot systems through environment partitioning for adaptive informative sampling,” 2019 Int. Conf. on Robotics and Automation, pp. 3231-3237, 2019. https://doi.org/10.1109/ICRA.2019.8794103

- [56] D.-J. Xie et al., “Base position planning of mobile manipulators for assembly tasks in construction environments,” Advances in Manufacturing, Vol.11, No.1, pp. 93-110, 2023. https://doi.org/10.1007/s40436-022-00411-3

- [57] M. Yao et al., “Object-level complete coverage path planning for excavators in earthwork construction,” Scientific Reports, Vol.13, Article No.12818, 2023. https://doi.org/10.1038/s41598-023-40038-3

- [58] S. Teng et al., “FusionPlanner: A multi-task motion planner for mining trucks via multi-sensor fusion,” Mechanical Systems and Signal Processing, Vol.208, Article No.111051, 2024. https://doi.org/10.1016/j.ymssp.2023.111051

- [59] K. Ishikawa et al., “Automatic excavation system with multiple excavators in the pneumatic caisson method,” J. Robot. Mechatron., Vol.36, No.4, pp. 961-972, 2024. https://doi.org/10.20965/jrm.2024.p0961

- [60] M. Zhang et al., “A task allocation method for clustered multi-intelligent body networks,” CN Patent, CN202210369927.7, 2022.

- [61] L. Li, Z. Chen, H. Wang, and Z. Kan, “Fast task allocation of heterogeneous robots with temporal logic and inter-task constraints,” IEEE Robotics and Automation Letters, Vol.8, No.8, pp. 4991-4998, 2023. https://doi.org/10.1109/LRA.2023.3290531

- [62] Y. Bota, H. Mizuyama, A. Noda, T. Nagatani, and K. Tanaka, “A tree-shaped motion strategy for robustly executing robotic assembly tasks,” J. of Zhejiang University—SCIENCE A, Vol.11, No.12, pp. 986-991, 2010. https://doi.org/10.1631/jzus.A1001436

- [63] Z. Xing, X. Wang, S. Wang, W. Wu, and R. Hu, “A novel motion coordination method for variable-sized multi-mobile robots,” Frontiers of Information Technology & Electronic Engineering, Vol.24, No.4, pp. 521-535, 2023. https://doi.org/10.1631/fitee.2200160

- [64] J. Kim, D. Lee, and J. Seo, “Task planning strategy and path similarity analysis for an autonomous excavator,” Automation in Construction, Vol.112, Article No.103108, 2020. https://doi.org/10.1016/j.autcon.2020.103108

- [65] Z. He, S. L. Yuan, Z. Zhang, and C. Gu, “A multi-intelligence body optimal task allocation and planning method, device, and system based on a base-coda graph,” CN Patent, CN202311605617.1, 2024.

- [66] J. Guo, X. Huo, S. Guo, and J. Xu, “A path planning method for the spherical amphibious robot based on improved A-star algorithm,” 2021 IEEE Int. Conf. on Mechatronics and Automation, pp. 1274-1279, 2021. https://doi.org/10.1109/ICMA52036.2021.9512805

- [67] N. Wang et al., “Collaborative path planning and task allocation for multiple agricultural machines,” Computers and Electronics in Agriculture, Vol.213, Article No.108218, 2023. https://doi.org/10.1016/j.compag.2023.108218

- [68] Y. Gao et al., “Improved particle swarm algorithm based on non-dominated ordering for collaborative task allocation of multiple intelligences,” CN Patent, CN202211459220.1, 2023.

- [69] Y. Zhang, Q. Fu, and G. Shan, “A multi-sensor-system cooperative scheduling method for ground area detection and target tracking,” Frontiers of Information Technology & Electronic Engineering, Vol.24, No.2, pp. 245-258, 2023. https://doi.org/10.1631/fitee.2200121

- [70] I. Niskanen et al., “Determining payload on platform of lorry in real time using integrated 3-D lidar from excavator boom,” IEEE Trans. on Instrumentation and Measurement, Vol.73, Article No.5007607, 2024. https://doi.org/10.1109/TIM.2024.3350119

- [71] A. Amirkhani and A. H. Barshooi, “Consensus in multi-agent systems: A review,” Artificial Intelligence Review, Vol.55, No.5, pp. 3897-3935, 2022. https://doi.org/10.1007/s10462-021-10097-x

- [72] J. Huh et al., “Deep learning-based autonomous excavation: A bucket-trajectory planning algorithm,” IEEE Access, Vol.11, pp. 38047-38060, 2023. https://doi.org/10.1109/ACCESS.2023.3267120

- [73] Z. Zou, J. Chen, and X. Pang, “Task space-based dynamic trajectory planning for digging process of a hydraulic excavator with the integration of soil–bucket interaction,” Proc. of the Institution of Mechanical Engineers, Part K: J. of Multi-body Dynamics, Vol.233, No.3, pp. 598-616, 2019. https://doi.org/10.1177/1464419318812589

- [74] J. Zhao, Y. Hu, C. Liu, M. Tian, and X. Xia, “Spline-based optimal trajectory generation for autonomous excavator,” Machines, Vol.10, No.7, Article No.538, 2022. https://doi.org/10.3390/machines10070538

- [75] J. Yang, Y. Gao, R. Guo, Q. Gao, and J. Zhao, “Research on excavator trajectory control based on hybrid interpolation,” Sustainability, Vol.15, No.8, Article No.6761, 2023. https://doi.org/10.3390/su15086761

- [76] H. Feng et al., “Multi-objective time-energy-impact optimization for robotic excavator trajectory planning,” Automation in Construction, Vol.156, Article No.105094, 2023. https://doi.org/10.1016/j.autcon.2023.105094

- [77] Y. Yang, P. Long, X. Song, J. Pan, and L. Zhang, “Optimization-based framework for excavation trajectory generation,” IEEE Robotics and Automation Letters, Vol.6, No.2, pp. 1479-1486, 2021. https://doi.org/10.1109/LRA.2021.3058071

- [78] C. Feng et al., “Task-unit based trajectory generation for excavators utilizing expert operator skills,” Automation in Construction, Vol.158, Article No.105247, 2024. https://doi.org/10.1016/j.autcon.2023.105247

- [79] K. Hiraoka, T. Yamamoto, M. Kozui, K. Koiwai, and K. Yamashita, “Design of a database-driven assist control for a hydraulic excavator considering human operation,” J. Robot. Mechatron., Vol.35, No.3, pp. 703-710, 2023. https://doi.org/10.20965/jrm.2023.p0703

- [80] Z. Yao, S. Zhao, X. Tan, W. Wei, and Y. Wang, “Real-time task-oriented continuous digging trajectory planning for excavator arms,” Automation in Construction, Vol.152, Article No.104916, 2023. https://doi.org/10.1016/j.autcon.2023.104916

- [81] T. Zhang et al., “Data-driven excavation trajectory planning for unmanned mining excavator,” Automation in Construction, Vol.162, Article No.105395, 2024. https://doi.org/10.1016/j.autcon.2024.105395

- [82] Z. Niu, G. Zhong, and H. Yu, “A review on the attention mechanism of deep learning,” Neurocomputing, Vol.452, pp. 48-62, 2021. https://doi.org/10.1016/j.neucom.2021.03.091

- [83] G. Liu, Q. Wang, B. Li, and X. Xi, “Calibration of visual measurement system for excavator manipulator pose,” Measurement Science and Technology, Vol.35, No.7, Article No.075901, 2024. https://doi.org/10.1088/1361-6501/ad37d2

- [84] G. Liu, Q. Wang, and T. Wang, “A new measurement method of real-time pose estimation for an automatic hydraulic excavator,” 2022 IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics, pp. 308-313, 2022. https://doi.org/10.1109/AIM52237.2022.9863349

- [85] Y. Huang, Y. Wang, and O. Zatarain, “Dynamic path optimization for robot route planning,” IEEE 18th Int. Conf. on Cognitive Informatics & Cognitive Computing, pp. 47-53, 2019. https://doi.org/10.1109/ICCICC46617.2019.9146050

- [86] S.-K. Kim, J. Seo, and J. S. Russell, “Intelligent navigation strategies for an automated earthwork system,” Automation in Construction, Vol.21, pp. 132-147, 2012. https://doi.org/10.1016/j.autcon.2011.05.021

- [87] Y. Lei, Y. Wang, S. Wu, X. Gu, and X. Qin, “A fuzzy logic-based adaptive dynamic window approach for path planning of automated driving mining truck,” 2021 IEEE Int. Conf. on Mechatronics, 2021. https://doi.org/10.1109/ICM46511.2021.9385634

- [88] E. J. Molinos, Á. Llamazares, and M. Ocaña, “Dynamic window based approaches for avoiding obstacles in moving,” Robotics and Autonomous Systems, Vol.118, pp. 112-130, 2019. https://doi.org/10.1016/j.robot.2019.05.003

- [89] G. Luo and Y. Shen, “A study on path optimization of construction machinery by fusing ant colony optimization and artificial potential field,” Advanced Control for Applications, Vol.6, No.2, Article No.e125, 2024. https://doi.org/10.1002/adc2.125

- [90] Y. Fang et al., “Research on path planning and trajectory tracking of an unmanned electric shovel based on improved APF and preview deviation fuzzy control,” Machines, Vol.10, No.8, Article No.707, 2022. https://doi.org/10.3390/machines10080707

- [91] Z. Zhu et al., “Path tracking control of autonomous agricultural mobile robots,” J. of Zhejiang University—SCIENCE A, Vol.8, No.10, pp. 1596-1603, 2007. https://doi.org/10.1631/jzus.2007.A1596

- [92] W. Chen, Y. Chen, and Y. Zhang, “Finite-time coordinated path-following control of leader-following multi-agent systems,” Frontiers of Information Technology & Electronic Engineering, Vol.23, No.10, pp. 1511-1521, 2022. https://doi.org/10.1631/fitee.2100476

- [93] T. Han et al., “Multi-formation control of nonlinear leader-following multi-agent systems,” ISA Trans., Vol.69, pp. 140-147, 2017. https://doi.org/10.1016/j.isatra.2017.05.003

- [94] J. Petereit, “Adaptive state × time lattices: A contribution to mobile robot motion planning in unstructured dynamic environments,” KIT Scientific Publishing, 2016. https://doi.org/10.5445/KSP/1000058693

- [95] N. T. Lam, I. Howard, and L. Cui, “A review of trajectory planning for autonomous excavator in construction and mining sites,” 10th Australasian Congress on Applied Mechanics (ACAM 10), pp. 368-382, 2021. https://doi.org/10.3316/informit.323406814564895

- [96] S.-K. Kim, J. S. Russell, and K.-J. Koo, “Construction robot path-planning for earthwork operations,” J. of Computing in Civil Engineering, Vol.17, No.2, pp. 97-104, 2003. https://doi.org/10.1061/(ASCE)0887-3801(2003)17:2(97)

- [97] D. Fox, W. Burgard, and S. Thrun, “The dynamic window approach to collision avoidance,” IEEE Robotics & Automation Magazine, Vol.4, No.1, pp. 23-33, 1997. https://doi.org/10.1109/100.580977

- [98] M. I. Mahfouz, M. M. Rashwan, Z. A. Khadr, and M. A. Ramadan, “Multi-objective mathematical programming approach for multivariate compromise allocation for stratified random sampling,” Communications in Statistics – Simulation and Computation, 2024. https://doi.org/10.1080/03610918.2024.2309962

- [99] C. C. W. Chang et al., “Nature-inspired heuristic frameworks trends in solving multi-objective engineering optimization problems,” Archives of Computational Methods in Engineering, Vol.31, No.6, pp. 3551-3584, 2024. https://doi.org/10.1007/s11831-024-10090-x

- [100] J. R. Sánchez-Ibáñez, C. J. Pérez-del-Pulgar, and A. García-Cerezo, “Path planning for autonomous mobile robots: A review,” Sensors, Vol.21, No.23, Article No.7898, 2021. https://doi.org/10.3390/s21237898

- [101] W. Liu, X. Zheng, and Z. Deng, “Dynamic collision avoidance for cooperative fixed-wing UAV swarm based on normalized artificial potential field optimization,” J. of Central South University, Vol.28, No.10, pp. 3159-3172, 2021. https://doi.org/10.1007/s11771-021-4840-5

- [102] C. I. Connolly, J. B. Burns, and R. Weiss, “Path planning using Laplace’s equation,” IEEE Int. Conf. on Robotics and Automation, Vol.3, pp. 2102-2106, 1990. https://doi.org/10.1109/ROBOT.1990.126315

- [103] R. Gu, “Automatic model generation and scalable verification for autonomous vehicles: mission planning and collision avoidance,” Licentiate thesis, Mälardalen University, 2020.

- [104] L. A. Trinh, M. Ekström, and B. Cürüklü, “Toward shared working space of human and robotic agents through dipole flow field for dependable path planning,” Frontiers in Neurorobotics, Vol.12, Article No.28, 2018. https://doi.org/10.3389/fnbot.2018.00028

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.