Development Report:

Remote Size Reduction by Hydraulic Cutter with Buffer Device Attached to Robotic Arm Using Visual Support System

Satoshi Iguchi*,†, Masato Yoshida*, Hiroshi Hirano*, Masaomi Wada**, Yoshihito Mori**, and Akihiro Kitamura*

*MOX Fuel Development Department, Japan Atomic Energy Agency

4-33 Muramatsu, Tokai-mura, Naka-gun, Ibaraki 319-1194, Japan

†Corresponding author

**Engineering Solution Division, Hitachi Plant Construction, Ltd.

3-1-3 Higashi-Ikebukuro, Toshima-ku, Tokyo 170-8630, Japan

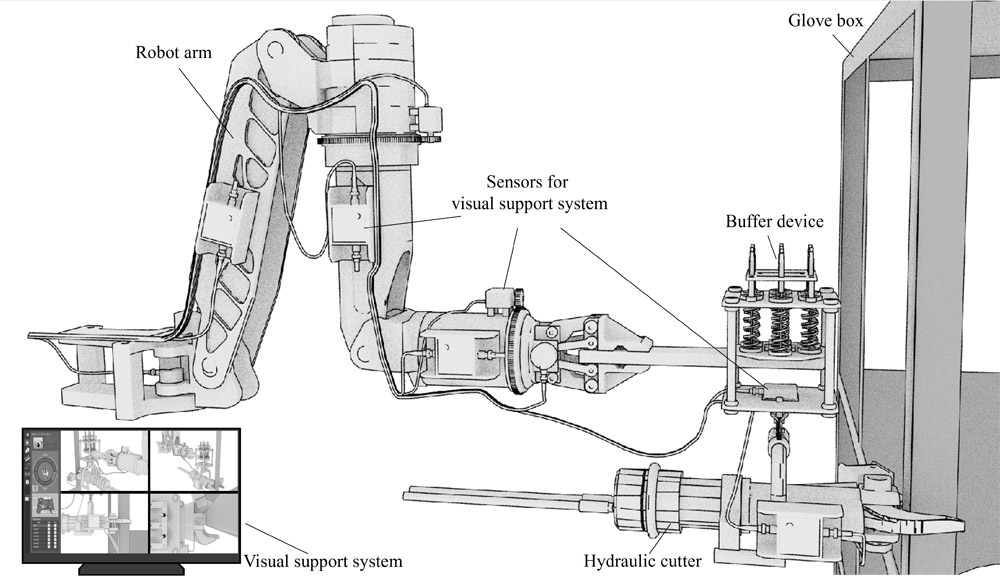

In nuclear fuel fabrication facilities, gloveboxes are typically dismantled manually. The integration of remotely controlled equipment, comprising a robot arm and a size reduction tool, can enhance work efficiency and mitigate radiation exposure risks in dismantling operations. The hydraulic cutter is regarded as a highly effective tool for reducing the size of steel frame structures, which are commonly composed of gloveboxes. However, when an object is severed by a hydraulic cutter fixed to a robot arm, the resultant reaction force may compromise the integrity of the robot arm or nearby structures. Consequently, in this study, we designed and manufactured a buffer device that can loosely hold the cutter to automatically align the object and absorb the reaction force. Furthermore, a visual support system was developed to assist the operator in performing remote dismantling operations. This system utilized a 3D viewer to project the robot arm, the buffer device, and the working environment. The functionality of the buffer device and 3D viewer was evaluated for the glovebox test bed. The experimental results satisfactorily confirmed the functionality of the buffer device to self-align the object and absorb sudden movements of the hydraulic cutter. Moreover, the 3D viewer provided the robot arm operator with an unobstructed perspective of the work environment, thereby confirming the efficacy of the visual support system in facilitating remote dismantling operations.

Effective devices for remote cutting

- [1] K. Tesch, M. W. Collins, T. G. Karayiannis, M. A. Atherton, and P. Edwards, “Heat and mass transfer in air-fed pressurized suits,” Applied Thermal Engineering, Vol.29, No.7, pp. 1375-1382, 2009. https://doi.org/10.1016/j.applthermaleng.2008.03.045

- [2] A. Kitamura, H. Hirano, M. Yoshida, and K. Takeuchi, “Experiences in dismantlement of gloveboxes for wet recovery and other use that are contaminated with nuclear fuel materials,” Japanese J. of Health Physics, Vol.58, No.2, pp. 76-90, 2023 (in Japanese). https://doi.org/10.5453/jhps.58.76

- [3] L. Hao, J. Qi, R. Wang, Y. Yi, and J. Wu, “Protective performance test and safety risk evaluation of a powered air-purifying suit,” Biosafety and Health, Vol.1, No.2, pp. 91-97, 2019. https://doi.org/10.1016/j.bsheal.2019.08.002

- [4] J. Wang et al., “Control strategy of master-slave manipulator based on force feedback for decommissioning of nuclear facilities,” Mathematical Problems in Engineering, Vol.2022, Article No.9945758, 2022. https://doi.org/10.1155/2022/9945758

- [5] N. Mizuno, Y. Tazaki, T. Hashimoto, and Y. Yokokohji, “A comparative study of manipulator teleoperation methods for debris retrieval phase in nuclear power plant decommissioning,” Advanced Robotics, Vol.37, No.9, pp. 541-559, 2023. https://doi.org/10.1080/01691864.2023.2169588

- [6] T. Hashimoto et al., “Experimental evaluation of manipulator teleoperation system based on trajectory planning for obstacle removal task in nuclear plant decommissioning,” J. Robot. Mechatron., Vol.36, No.1, pp. 49-62, 2024. https://doi.org/10.20965/jrm.2024.p0049

- [7] A. Kitamura, H. Hirano, and M. Yoshida, “Comparative study of a glovebox dismantling facility for manual and remote glovebox dismantlement activities,” Nuclear Engineering and Design, Vol.411, Article No.112435, 2023. https://doi.org/10.1016/j.nucengdes.2023.112435

- [8] G.-R. Lee, B.-J. Lim, D.-W. Cho, and C.-D. Park, “Selection methodology of the optimal cutting technology for dismantling of components in nuclear power plants,” Annals of Nuclear Energy, Vol.166, Article No.108808, 2022. https://doi.org/10.1016/j.anucene.2021.108808

- [9] M.-G. Choi, D.-H. Lee, S.-M. Jeong, D. Figuera-Michal, and J.-H. Seo, “A hybrid cutting technology using plasma and end mill for decommissioning of nuclear facilities,” Nuclear Engineering and Technology, Vol.54, No.3, pp. 1145-1151, 2022. https://doi.org/10.1016/j.net.2021.09.012

- [10] J. S. Shin et al., “Cutting performance of thick steel plates up to 150 mm in thickness and large size pipes with a 10-kW fiber laser for dismantling of nuclear facilities,” Annals of Nuclear Energy, Vol.122, pp. 62-68, 2018. https://doi.org/10.1016/j.anucene.2018.08.029

- [11] A. Kitamura, K. Nakai, T. Namekawa, and M. Watahiki, “In-cell maintenance by manipulator arm with 3D workspace information recreated by laser rangefinder,” Nuclear Engineering and Design, Vol.241, No.7, pp. 2614-2623, 2011. https://doi.org/10.1016/j.nucengdes.2011.04.044

- [12] K. Nagatani et al., “Emergency response to the nuclear accident at the Fukushima Daiichi Nuclear Power Plants using mobile rescue robots,” J. of Field Robotics, Vol.30, No.1, pp. 44-63, 2013. https://doi.org/10.1002/rob.21439

- [13] I. Kim, D. Hyun, S. Joo, and J. Lee, “A methodology for digital mockup update based on the 3D scanned spatial information for the automated dismantling of nuclear facilities,” Annals of Nuclear Energy, Vol.139, Article No.107238, 2020. https://doi.org/10.1016/j.anucene.2019.107238

- [14] A. K. Sleiti, J. S. Kapat, and L. Vesely, “Digital twin in energy industry: Proposed robust digital twin for power plant and other complex capital-intensive large engineering systems,” Energy Reports, Vol.8, pp. 3704-3726, 2022. https://doi.org/10.1016/j.egyr.2022.02.305

- [15] T. Inamura, “Digital twin of experience for human–robot collaboration through virtual reality,” Int. J. Automation Technol., Vol.17, No.3, pp. 284-291, 2023. https://doi.org/10.20965/ijat.2023.p0284

- [16] P. Satu et al., “Virtual-reality training solutions for nuclear power plant field operators: A scoping review,” Progress in Nuclear Energy, Vol.169, Article No.105104, 2024. https://doi.org/10.1016/j.pnucene.2024.105104

- [17] B. Nash, A. Walker, and T. Chambers, “A simulator based on virtual reality to dismantle a research reactor assembly using master-slave manipulators,” Annals of Nuclear Energy, Vol.120, pp. 1-7, 2018. https://doi.org/10.1016/j.anucene.2018.05.018

- [18] K. Jeong et al., “The digital mock-up system to simulate and evaluate the dismantling scenarios for decommissioning of a NPP,” Annals of Nuclear Energy, Vol.69, pp. 238-245, 2014. https://doi.org/10.1016/j.anucene.2014.02.020

- [19] D. Hyun, I. Kim, S. Joo, J. Ha, and J. Lee, “Remote dismantling system using a digital manufacturing system and workpiece localization for nuclear facility decommissioning,” Annals of Nuclear Energy, Vol.195, Article No.110182, 2024. https://doi.org/10.1016/j.anucene.2023.110182

- [20] I. Szőke, M. N. Louka, T.-R. Bryntesen, S.-T. Edvardsen, and J. Bratteli, “Comprehensive support for nuclear decommissioning based on 3D simulation and advanced user interface technologies,” J. of Nuclear Science and Technology, Vol.52, No.3, pp. 371-387, 2015. https://doi.org/10.1080/00223131.2014.951704

- [21] M. Yoshida, S. Iguchi, H. Hirano, and A. Kitamura, “Development of plutonium fuel facility decommissioning technology to accelerate glovebox dismantling and reduce air-fed suits based operations,” Nuclear Engineering and Design, Vol.431, Article No.113691, 2025. https://doi.org/10.1016/j.nucengdes.2024.113691

- [22] S. Sivčev, J. Coleman, E. Omerdić, G. Dooly, and D. Toal, “Underwater manipulators: A review,” Ocean Engineering, Vol.163, pp. 431-450, 2018. https://doi.org/10.1016/j.oceaneng.2018.06.018

- [23] K. Jeong et al., “An evaluation on the cutting technologies for decommissioning of the tube bundles in the RPV of NPPs,” Annals of Nuclear Energy, Vol.83, pp. 342-345, 2015. https://doi.org/10.1016/j.anucene.2015.03.038

- [24] Y. Mori and M. Wada, “Development of 3D digital-twin system for remote-control operation in construction,” Proc. of the 41st Int. Symp. on Automation and Robotics in Construction, pp. 958-964, 2024. https://doi.org/10.22260/ISARC2024/0124

- [25] H. Kikuchi, H. Hirano, and A. Kitamura, “Safety improvements in demolition and removal activities with air-fed suit for plutonium fuel facility decommissioning,” Trans. of the Atomic Energy Society of Japan, Vol.21, No.1, pp. 50-63, 2022 (in Japanese). https://doi.org/10.3327/taesj.J20.035

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.