Paper:

Variable-Sensitivity Force Sensor Utilizing Modified Cross-Sectional Shape

Kazuto Takashima†

, Shunsuke Tsuji, and Kengo Ota

, Shunsuke Tsuji, and Kengo Ota

Graduate School of Life Science and Systems Engineering, Kyushu Institute of Technology

2-4 Hibikino, Wakamatsu-ku, Kitakyushu, Fukuoka 808-0196, Japan

†Corresponding author

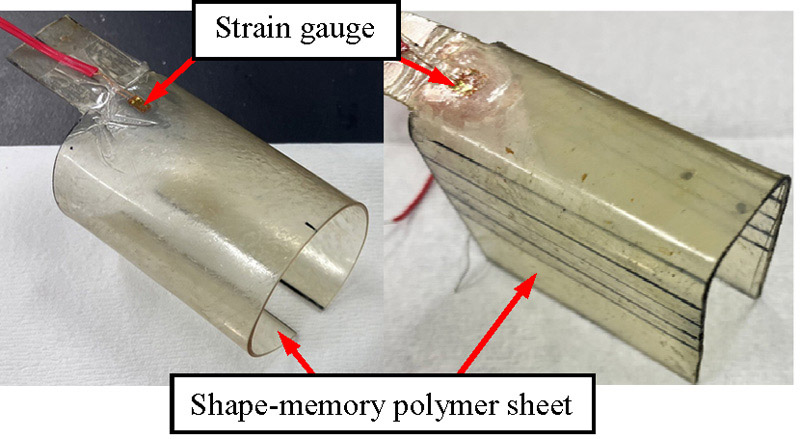

Force sensors require different measurement ranges and sensitivities depending on the operating environment. Therefore, we developed a force sensor with both variable sensitivity and measurement range based on structural modification induced by simple bending. In our previous study, we changed the distance between the force application point and the detection area. However, it was necessary to change the position and direction of the measured force. Therefore, in the present study, we changed the cross-sectional shape of the sensor. First, we introduce the theoretical basis for the proposed force sensor. We then describe prototype sensors and the experimental methods used to determine their performance. We fabricated the prototypes by attaching a strain gauge to one side of shape-memory polymer plates, which can be deformed at temperatures above the glass transition temperature (Tg) by applying a small load and maintain their rigid shape after they have been cooled below Tg. We designed two types of sensor with different cross-sectional shapes (i.e., hollow cylinder and channel beam) and experimentally evaluated them. The results indicated that the sensitivity and measurement range of the sensor can be changed by modifying the cross-sectional shape. For example, for hollow cylinder and channel beam types of sensor, the maximum change in sensitivity before and after bending was 6.2 and 2.7 times, respectively. Although these values were smaller than that (12 times) obtained in our previous study, it was possible to change the sensitivity without changing the position or direction of the measured force.

Prototype force sensors

- [1] K. Suzumori and H. Nabae, “Review of flexible/stretchable sensors for soft robot,” J. Robot. Mechatron., Vol.37, No.1, pp. 8-12, 2025. https://doi.org/10.20965/jrm.2025.p0008

- [2] W. Jiang, Z. Luo, W. Wang, J. Liu, and L. Zhang, “Dynamic sensitivity evaluation for force transducers by using a gray-bootstrap method,” IEEE Sens. J., Vol.23, No.23, pp. 29019-29028, 2023. https://doi.org/10.1109/JSEN.2023.3323783

- [3] F. J. Abu-Dakka and M. Saveriano, “Variable impedance control and learning—A review,” Front. Robot. AI, Vol.7, Article No.590681, 2020. https://doi.org/10.3389/frobt.2020.590681

- [4] J. Fraden, “Handbook of Modern Sensors: Physics, Designs, and Applications,” 3rd Edition, Springer, 2003.

- [5] Y. Murozaki, S. Sakuma, and F. Arai, “Improvement of the measurement range and temperature characteristics of a load sensor using a quartz crystal resonator with all crystal layer components,” Sensors, Vol.17, No.5, Article No.1067, 2017. https://doi.org/10.3390/s17051067

- [6] J. Jiang, W. Chen, J. Liu, W. Chen, and J. Zhang, “Optimum design of a dual-range force sensor for achieving high sensitivity, broad bandwidth, and large measurement range,” IEEE Sens. J., Vol.15, No.2, pp. 1114-1123, 2015. https://doi.org/10.1109/JSEN.2014.2360885

- [7] D. Okumura, S. Sakaino, and T. Tsuji, “High dynamic range sensing by a multistage six-axis force sensor with stopper mechanism,” 2018 IEEE Int. Conf. Robot. Autom., pp. 4065-4070, 2018. https://doi.org/10.1109/ICRA.2018.8460571

- [8] R. Tamura, S. Sakaino, and T. Tsuji, “Development of compact high dynamic range six-axis force sensor with cross-arch structure,” 45th Annu. Conf. IEEE Ind. Electron. Soc., pp. 3609-3614, 2019. https://doi.org/10.1109/IECON.2019.8926830

- [9] T. Kawahara and T. Tsuji, “Development of high dynamic range six-axis force sensor with simple structure,” J. Robot. Mechatron., Vol.35, No.3, pp. 771-779, 2023. https://doi.org/10.20965/jrm.2023.p0771

- [10] R. Tamura, S. Sakaino, and T. Tsuji, “High dynamic range uniaxial force/torque sensor using metal foil and semiconductor strain gauge,” IEEJ J. Ind. Appl., Vol.10, No.5, pp. 506-511, 2021. https://doi.org/10.1541/IEEJJIA.20007411

- [11] S. Zhuo, C. Song, Q. Rong, T. Zhao, and M. Liu, “Shape and stiffness memory ionogels with programmable pressure-resistance response,” Nat. Commun., Vol.13, Article No.1743, 2022. https://doi.org/10.1038/s41467-022-29424-z

- [12] W. Yue et al., “Origami-inspired structure with pneumatic-induced variable stiffness for multi-DOF force-sensing,” Sensors, Vol.22, No.14, Article No.5370, 2022. https://doi.org/10.3390/S22145370

- [13] X. Sun, W. Chen, X. Xiong, W. Chen, and Y. Jin, “A variable configuration force sensor with adjustable resolution for robotic applications,” IEEE Trans. Ind. Electron., Vol.70, No.2, pp. 2066-2075, 2023. https://doi.org/10.1109/TIE.2022.3163538

- [14] A. Faragasso et al., “Novel uniaxial force sensor based on visual information for minimally invasive surgery,” 2014 IEEE Int. Conf. Robot. Autom., pp. 1405-1410, 2014. https://doi.org/10.1109/ICRA.2014.6907036

- [15] C. Hou et al., “A highly integrated 3D MEMS force sensing module with variable sensitivity for robotic-assisted minimally invasive surgery,” Adv. Funct. Mater., Vol.33, No.43, Article No.2302812, 2023. https://doi.org/10.1002/ADFM.202302812

- [16] M. Maroufi, H. Alemansour, M. B. Coskun, and S. O. R. Moheimani, “An adjustable-stiffness MEMS force sensor: Design, characterization, and control,” Mechatronics, Vol.56, pp. 198-210, 2018. https://doi.org/10.1016/J.MECHATRONICS.2018.05.007

- [17] A. Nastro, M. Ferrari, and V. Ferrari, “Double-actuator position-feedback mechanism for adjustable sensitivity in electrostatic-capacitive MEMS force sensors,” Sens. Actuators A: Phys., Vol.312, Article No.112127, 2020. https://doi.org/10.1016/J.SNA.2020.112127

- [18] R. Horie and M. Kaneko, “A sensitivity variable tactile sensor with self-tuner,” J. Robot. Soc. Jpn., Vol.21, No.8, pp. 940-946, 2003 (in Japanese). https://doi.org/10.7210/JRSJ.21.940

- [19] S. Kouno, “A sensitivity variable tactile sensor with self-tuner,” J. Robot. Mechatron., Vol.18, No.1, pp. 83-88, 2006. https://doi.org/10.20965/JRM.2006.P0083

- [20] K. Takashima, H. Kamizono, M. Takenaka, and T. Mukai, “Force sensor utilizing stiffness change of shape-memory polymer based on temperature,” ROBOMECH J., Vol.4, Article No.17, 2017. https://doi.org/10.1186/s40648-017-0086-2

- [21] K. Takashima, J. Kobuchi, N. Kamamichi, K. Takagi, and T. Mukai, “Characterization of variable-sensitivity force sensor using stiffness change of shape-memory polymer based on temperature,” ROBOMECH J., Vol.8, Article No.24, 2021. https://doi.org/10.1186/s40648-021-00210-8

- [22] K. Takashima, K. Ota, and H. Cho, “Variable-sensitivity force sensor based on structural modification,” Sensors, Vol.23, No.4, Article No.2077, 2023. https://doi.org/10.3390/s23042077

- [23] J. M. Jani, M. Leary, A. Subic, and M. A. Gibson, “A review of shape memory alloy research, applications and opportunities,” Mater. Des., Vol.56, pp. 1078-1113, 2014. https://doi.org/10.1016/j.matdes.2013.11.084

- [24] K. Takashima et al., “Development and application of shape-memory polymer and alloy composite sheets,” J. Robot. Mechatron., Vol.36, No.3, pp. 769-778, 2024. https://doi.org/10.20965/jrm.2024.p0769

- [25] C.-T. Chen and R.-C. Peng, “Design and 3D printing of paper-based shape memory polymer actuated for soft lightweight fingers,” Smart Mater. Struct., Vol.30, No.7, Article No.075010, 2021. https://doi.org/10.1088/1361-665X/ac00ca

- [26] I. Abavisani, O. Rezaifar, and A. Kheyroddin, “Multifunctional properties of shape memory materials in civil engineering applications: A state-of-the-art review,” J. Build. Eng., Vol.44, Article No.102657, 2021. https://doi.org/10.1016/j.jobe.2021.102657

- [27] S. Yahara, S. Wakimoto, T. Kanda, and K. Matsushita, “McKibben artificial muscle realizing variable contraction characteristics using helical shape-memory polymer fibers,” Sens. Actuators A: Phys., Vol.295, pp. 637-642, 2019. https://doi.org/10.1016/j.sna.2019.06.012

- [28] N. Alberto et al., “Incorporation of fiber Bragg sensors for shape memory polyurethanes characterization,” Sensors, Vol.17, No.11, Article No.2600, 2017. https://doi.org/10.3390/S17112600

- [29] H. Meng et al., “Various shape memory effects of stimuli-responsive shape memory polymers,” Smart Mater. Struct., Vol.22, No.9, Article No.093001, 2013. https://doi.org/10.1088/0964-1726/22/9/093001

- [30] P. Ghosh, A. Rao, and A. R. Srinivasa, “Design of multi-state and smart-bias components using Shape Memory Alloy and Shape Memory Polymer composites,” Mater. Des., Vol.44, pp. 164-171, 2013. https://doi.org/10.1016/j.matdes.2012.05.063

- [31] Y. Liu, K. Gall, M. L. Dunn, A. R. Greenberg, and J. Diani, “Thermomechanics of shape memory polymers: Uniaxial experiments and constitutive modeling,” Int. J. Plast., Vol.22, No.2, pp. 279-313, 2006. https://doi.org/10.1016/j.ijplas.2005.03.004

- [32] G. Murasawa, S. Yoneyama, K. Tohgo, and M. Takashi, “Distribution of deformation and internal stress in shape memory alloy composite,” Trans. Jpn. Soc. Mech. Eng. A, Vol.71, No.705, pp. 780-788, 2005 (in Japanese). https://doi.org/10.1299/kikaia.71.780

- [33] A. Shimamoto, Y. Furuya, and M. Taya, “Active control of crack-tip stress intensity by contraction of shape memory TiNi fibers embedded in epoxy matrix composite: Dependency of stress intensity factor on crack-tip domain size,” Proc. of 11th Int. Conf. Compos. Mater., Vol.6, pp. 493-499, 1997.

- [34] A. T. Tung, B.-H. Park, D. H. Liang, and G. Niemeyer, “Laser-machined shape memory alloy sensors for position feedback in active catheters,” Sens. Actuators A: Phys., Vol.147, No.1, pp. 83-92, 2008. https://doi.org/10.1016/J.SNA.2008.03.024

- [35] S. Terrile, J. Miguelañez, and A. Barrientos, “A soft haptic glove actuated with shape memory alloy and flexible stretch sensors,” Sensors, Vol.21, No.16, Article No.5278, 2021. https://doi.org/10.3390/S21165278

- [36] S. H. Nahm, Y. J. Kim, J. M. Kim, and D.-J. Yoon, “A study on the application of Ni-Ti shape memory alloy as a sensor,” Mater. Sci. Forum, Vols.475-479, pp. 2043-2046, 2005. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/MSF.475-479.2043

- [37] The Japan Society of Mechanical Engineers (Eds.), “JSME Mechanical Engineers’ Handbook (DVD-ROM),” Maruzen Publishing, 2014 (in Japanese).

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.