Review:

Fluid-Driven Soft Actuators for Soft Robots

Taro Nakamura

Chuo University

1-13-27 Kasuga, Bunkyo-ku, Tokyo 112-8551, Japan

This paper focuses on soft actuators that utilize fluid power to drive soft robots and describes their features and applications. First, it discusses how soft actuators function as elemental technology in robots. This is followed by an introduction to the driving principle and features of fluid-driven soft actuators. It also classifies these soft actuators based on the fluid power source and the active mode of operation. Furthermore, an overview is provided on the materials employed in soft actuators and the control and evaluation methods for them. Finally, currently reported applications of these soft actuators, such as wearable devices, grippers, and bio-inspired robots, are presented.

Fluid driven soft actuator for soft-robotics

- [1] K. Suzumori, R. Niiyama, K. Fukuda, and K. Nakajima, “Special Issue on Science of Soft Robots,” J. Robot. Mechatron., Vol.34, No.2, pp. 193-194, 2022. https://doi.org/10.20965/jrm.2022.p0193

- [2] Y. Cao, J. Z. Shang, K. S. Liang, D. P. Fan, D. X. Ma, and L. Tang, “Review of Soft-Bodied Robots,” Chinese J. of Mechanical Engineering, Vol.48. No.3, pp. 25-33, 2012.

- [3] T. Nakamura, “Soft Robotics Based on Bio-Inspired System Design,” J. of Systems, Control and Information Engineers, Vol.61, No.7, pp. 265-270, 2017 (in Japanese). https://doi.org/10.11509/isciesci.61.7_265

- [4] N. El-Atab, R. B. Mishra, F. Al-Modaf, L. Joharji, A. A. Alsharif, H. Alamoudi, M. Diaz, N. Qaiser, and M. M. Hussain, “Soft Actuators for Soft Robotic Applications: A Review,” Advanced Intelligent Systems, Vol.2, No.10, Article No.2000128, 2020. https://doi.org/10.1002/aisy.202000128

- [5] L. Hines, K. Petersen, G. Z. Lum, and M. Sitti, “Soft Actuators for Small-Scale Robotics,” Advanced Materials, Vol.29, No.13, Article No.1603483, 2017. https://doi.org/10.1002/adma.201603483

- [6] M. Li, A. Pal, A. Aghakhani, A. Pena-Francesch, and M. Sitti, “Soft Actuators for Real-World Applications,” Nature Reviews Materials, Vol.7, pp. 235-249, 2022. https://doi.org/10.1038/s41578-021-00389-7

- [7] J. Walker, T. Zidek, C. Harbel, S. Yoon, F. S. Strickland, S. Kumar, and M. Shin, “Soft Robotics: A Review of Recent Developments of Pneumatic Soft Actuators,” Actuators, Vol.9, No.1, Article No.3, 2020. https://doi.org/10.3390/act9010003

- [8] H. Su, X. Hou, X. Zhang, W. Qi, S. Cai, X. Xiong, and J. Guo, “Pneumatic Soft Robots: Challenges and Benefits,” Actuators, Vol.11, No.3, Article No.92, 2022. https://doi.org/10.3390/act11030092

- [9] T. Nakamura and H. Shinohara, “Position and Force Control Based on Mathematical Models of Pneumatic Artificial Muscles Reinforced by Straight Glass Fibers,” Proc. 2017 IEEE Int. Conf. on Robotics and Automation, pp. 4361-4366, 2007. https://doi.org/10.1109/ROBOT.2007.364151

- [10] T. Noritsugu, “Pneumatic Soft Actuator for Human Assist Technology,” Proc. of the 6th JFPS Int. Symp. on Fluid Power, pp. 11-20, 2005.

- [11] J. Bishop-Moser and S. Kota, “Design and Modeling of Generalized Fiber-Reinforced Pneumatic Soft Actuators,” IEEE Trans. on Robotics, Vol.31, Issue 3, pp. 536-545, 2005. https://doi.org/10.1109/TRO.2015.2409452

- [12] G. K. Klute and B. Hannaford, “Fatigue Characteristics of McKibben Artificial Muscle Actuators,” Proc. of the 1998 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems. Innovations in Theory, Practice and Applications, pp. 1776-1781, 1998. https://doi.org/10.1109/IROS.1998.724854

- [13] M. Okui, A. Kojima, I. Hisamichi, S. Kuriyama, T. Kojima, T. Tsuji, and T. Nakamura, “Prolonging Rubber Fatigue Life Using Hysteresis of Strain-Induced Crystallization of Natural Rubber,” Polymer Testing, Vol.117, Article No.107800, 2023. https://doi.org/10.1016/j.polymertesting.2022.107800

- [14] F. Connolly, P. Polygerinos, C. J. Walsh, and K. Bertoldi, “Mechanical Programming of Soft Actuators by Varying Fiber Angle,” Soft Robotics, Vol.2, No.1, 2015. https://doi.org/10.1089/soro.2015.0001

- [15] G. Singh and G. Krishnan, “Designing Fiber-Reinforced Soft Actuators for Planar Curvilinear Shape Matching,” Soft Robotics, Vol.2, No.1, 2020. https://doi.org/10.1089/soro.2018.0169

- [16] F. Connolly and C. J. Walsh, “Automatic Design of Fiber-Reinforced Soft Actuators for Trajectory Matching,” Proc. of the National Academy of Sciences, Vol.114, No.1, pp. 51-56, 2017. https://doi.org/10.1073/pnas.1615140114

- [17] S. Konishi, K. Yoshida, J.-W. Kim, and M. D. Volder, “Elastic Inflatable Actuators for Soft Robotic Applications,” Advanced Materials, Vol.29, Issue 43, Article No.1604977, 2017. https://doi.org/10.1002/adma.201604977

- [18] Y. Sun, Y. S. Song, and J. Paik, “Characterization of Silicone Rubber Based Soft Pneumatic Actuators,” 2013 IEEE/RSJ Int. Conf. on Intelligent Robot Systems, pp. 4456-4453, 2013. https://doi.org/10.1109/IROS.2013.6696995

- [19] L. Paez, G. Agarwal, and J. Paik, “Design and Analysis of a Soft Pneumatic Actuator with Origami Shell Reinforcement,” Soft Robotics, Vol.3, Issue 3, pp. 109-119, 2016. https://doi.org/10.1089/soro.2016.0023

- [20] M. Okui, Y. Nagura, Y. Yamada, and T. Nakamura, “Hybrid Pneumatic Source Based on Evaluation of Air Compression Methods for Portability,” IEEE Robotics and Automation Letters, Vol.3, Issue 2, pp. 819-826, 2018. https://doi.org/10.1109/LRA.2018.2792145

- [21] O. Azami, K. Ishibashi, M. Komagata, and K. Yamamoto, “Development of Hydraulically-Driven Soft Hand for Handling Heavy Vegetables and Its Experimental Evaluation,” IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 2577-2583, 2023. https://doi.org/10.1109/ICRA48891.2023.10160629

- [22] Y. Feng, T. Ide, H. Nabae, G. Endo, R. Sakurai, S. Ohno, and K. Suzumori, “Safety-Enhanced Control Strategy of a Power Soft Robot Driven by Hydraulic Artifcial Muscles,” Robomech J., Vol.8, Article No.10, 2021. https://doi.org/10.1186/s40648-021-00194-5

- [23] R. Tiwari, M. A. Meller, K. B. Wajcs, C. Moses, I. Reveles, and E. Garcia, “Hydraulic Artifcial Muscles,” J. of Intelligent Material Systems and Structures, Vol.23, Issue 3, pp. 301-312, 2012. https://doi.org/10.1177/1045389X12438627

- [24] M. Focchi, E. Guglielmino, C. Semini, A. Parmiggiani, N. Tsagarakis, B. Vanderborght, and D. G. Caldwell, “Water/Air Performance Analysis of a Fuidic Muscle,” 2010 IEEE/RSJ Int. Conf. on Intelligent Robots, pp. 2194-2199, 2010. https://doi.org/10.1109/IROS.2010.5650432

- [25] K. McDonald, A. Rendos, S. Woodman, K. A. Brown, and T. Ranzani, “Magnetorheological Fluid-Based Flow Control for Soft Robots,” Adv. Intelligent Systems, Vol.2, Issue 11, 2020. https://doi.org/10.1002/aisy.202000139

- [26] H. Taniguchi, M. Miyake, and K. Suzumori, “Development of New Soft Actuator Using Magnetic Intelligent Fluids for Flexible Walking Robot,” Int. Conf. on Control, Automation and Systems (ICCAS), pp. 1797-1801, 2010. https://doi.org/10.1109/ICCAS.2010.5669801

- [27] N. Saga and T. Nakamura, “Development of a Peristaltic Crawling Robot Using Magnetic Fluid on the Basis of the Locomotion Mechanism of the Earthworm,” Smart Materials and Structures, Vol.13, No.3, pp. 566-569, 2004. https://doi.org/10.1088/0964-1726/13/3/016

- [28] Y. Peng, D. Li, X. Yang, Z. Ma, and Z. Mao, “A Review on Electrohydrodynamic (EHD) Pump,” Micromachines, Vol.14, Issue 2, Article No.321, 2023. https://doi.org/10.3390/mi14020321

- [29] S. Yokota, F. Yajima, K. Takemura, and K. Edamura, “Electro-Conjugate Fluid Jet-Driven Micro Artificial Antagonistic Muscle Actuators and Their Integration,” Advanced Robotics, Vol.24, pp. 1929-1943, 2010. https://doi.org/10.1163/016918610X529048

- [30] R. Enjo, M. Okui, and T. Nakamura, “Pneumatic Source Proposal for Improving Portability and Responsiveness of Artificial Muscle via Dimethyl Ether Phase Change and Combustion,” Proc. 11th JFPS Int. Symp. on Fluid Power, pp. 169-174, 2021.

- [31] M. Okui, S. Iikawa, Y. Yamada, and T. Nakamura, “A Pneumatic Power Source Using a Sodium Bicarbonate and Citric Acid Reaction of for Use in Mobile Devices,” 2017 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 1040-1045, 2017. https://doi.org/10.1109/IROS.2017.8202272

- [32] K. Suzumori, A. Wada, and S. Wakimoto, “New Mobile Pressure Control System for Pneumatic Actuators, Using Reversible Chemical Reactions of Water,” Sensors and Actuators A: Physical, Vol.201, pp. 148-153, 2013. https://doi.org/10.1016/j.sna.2013.07.008

- [33] H. Wu, A. Kitagawa, and H. Tsukagoshi, “Development of a Portable Pneumatic Power Source Using Phase Transition at the Triple Point,” Proc. of the JFPS Int. Symp. on Fluid Power, Vol.2005, Issue 6, pp. 310-315, 2005. https://doi.org/10.5739/isfp.2005.310

- [34] H. Matsuoka and K. Suzumori, “Gas/Liquid Phase Change Actuator for Use in Extreme Temperature Environments,” Int. J. Automation Technol., Vol.8, No.2, pp. 140-146, 2014. https://doi.org/10.20965/ijat.2014.p0140

- [35] P. Lambe, H. Matsuoka, T. Kanda, S. Wakimoto, and K. Suzumori, “Development of a Rubber Soft Actuator Driven with Gas/Liquid Phase Change,” Int. J. Automation Technol., No.10, Vol.4, pp. 517-524, 2016. https://doi.org/10.20965/ijat.2016.p0517

- [36] Bridgestone Corporation, “Rubbertuators and Applications for Robots,” Technical Information, 1987.

- [37] J. R. Allen, A. Karchak, R. Snelson et al., “Design and Application of External Power and Control,” South Western Institute of Radio Engineers Convention, Abstract in Mechanical Engineering, pp. 52-53, 1962.

- [38] B. Tondu and P. Lopez, “Modeling and Control of McKibben Artificial Muscle Robot Actuators,” IEEE Control Systems Magazine, Vol.20, No.2, pp. 15-38, 2000. https://doi.org/10.1109/37.833638

- [39] J. L. McKibben, “Artlficlal Muscle,” Life, No.14, pp. 87-88, 1960.

- [40] J. Schulle, “The Characteristics of the McKibben Artificial Muscle,” The Application of External Power in Prosthetics and Orthotics, National Academy of Sciences-National Research Council, pp. 94-115, 1961.

- [41] H. A. Baldwin, “Realizable Models of Muscle Function,” Proc. of the 1st Rock Biomechanics Symp., pp. 139-148, 1969.

- [42] F. Daerden and D. Lefeber, “Pneumatic Artificial Muscles: Actuators for Robotics and Automation,” 2002 European J. of Mechanical and Environmental Engineering, Vol.47, No.1, pp. 11-21, 2002.

- [43] N. Saga, T. Nakamura, J. Uehara, and T. Iwade,, “Development of Artificial Muscle Actuator Reinforced by Kevlar Fiber,” 2002 IEEE Int. Conf. on Industrial Technology (ICIT’02), Vol.2, pp. 950-954, 2002. https://doi.org/10.1109/ICIT.2002.1189297

- [44] T. Nakamura, “Experimental Comparisons Between McKibben Type Artificial Muscles and Straight Fibers Type Artificial Muscles,” SPIE Int. Conf. on Smart Structures, Devices and Systems III, Article No.641426, 2006. https://doi.org/10.1117/12.698845

- [45] H. Tomori and T. Nakamura, “Theoretical Comparison of McKibben-Type Artificial Muscle and Novel Straight-Fiber-Type Artificial Muscle,” Int. J. Automation Technol., Vol.5, No.4, pp. 544-550, 2011. https://doi.org/10.20965/ijat.2011.p0544

- [46] F. Daerden, “Conception and Realization of Pleated Pneumatic Artificial Muscles and Their Use as Compliant Actua-Tion Elements,” Ph.D. Thesis, Vrije Universiteit Brussel, 1999.

- [47] F. Daerden, D. Lefeber, B. Verrelst, and R. Van Ham, “Pleated Pneumatic Artificial Muscles: Actuators for Automation and Robotics,” 2001 IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics, Vol.2, pp. 738-743, 2001. https://doi.org/10.1109/AIM.2001.936758

- [48] F. Ito, T. Itsuno, and T. Nakamura, “Development of Hyperextensible Pneumatic Soft Actuator that Extends 450% by Elongation of Rubber Material,” RSJ 2023 Annual Conf, 2B2-03, 2023 (in Japanese).

- [49] L. Fracczak, M. Nowak, and K. Koter, “Flexible Push Pneumatic Actuator With High Elongation,” Sensors and Actuators A: Physical, Vol.321, Article No.112578, 2021. https://doi.org/10.1016/j.sna.2021.112578

- [50] R. V. Martinez, C. R. Fish, X. Chen, and G. M. Whitesides, “Elastomeric Origami: Programmable Paper-Elastomer Composites as Pneumatic Actuators,” Advanced Functional Material, Vol.22, Issue 7, pp. 1376-1384, 2012. https://doi.org/10.1002/adfm.201102978

- [51] J. F. Wilson, “Mechanics of Bellows: A Critical Survey,” Int. J. of Mechanical Sciences, Vol.26, Issues 11-12, pp. 593-605, 1984. https://doi.org/10.1016/0020-7403(84)90013-4

- [52] H.-W. Kang, I. H. Lee, and D.-W. Cho, “Development of a Micro-Bellows Actuator Using Micro-Stereolithography Technology,” Microelectronic Engineering, Vol.83, Issues 4-9, pp. 1201-1204 , 2006. https://doi.org/10.1016/j.mee.2006.01.228

- [53] C. Tawk, G. M. Spinks, M. in het Panhuis, and G. Alici, “3D Printable Linear Soft Vacuum Actuators: Their Modeling, Performance Quantification and Application in Soft Robotic Systems,” IEEE-ASME Trans. on Mechatronics, Vol.24, pp. 2118-2129, 2019. https://doi.org/10.1109/TMECH.2019.2933027

- [54] D. Yang, M. S. Verma, J. H. So, B. Mosadegh, C. Keplinger, B. Lee, F. Khashai, E. Lossner, and Z. Suo, “Buckling Pneumatic Linear Actuators Inspired by Muscle,” Advanced Materials Technologies, Vol.1, Issue 3, Article No.1600055, 2016.

- [55] P. Polygerinos, Z. Wang, J. T. B. Overvelde, K. C. Galloway, R. J. Wood, K. Bertoldi, and C. J. Walsh, “Modeling of Soft Fiber-Reinforced Bending Actuators,” IEEE Trans. on Robotics, Vol.31, Issue 3, pp. 778-789, 2015. https://doi.org/10.1109/TRO.2015.2428504

- [56] K. Suzumori, S. Iikura, and H. Tanaka, “Development of Flexible Microactuator and Its Applications to Robotic Mechanisms,” Proc. of 1991 IEEE Int. Conf. on Robotics and Automation, Vol.2, pp. 1622-1627, 1991. https://doi.org/10.1109/ROBOT.1991.131850

- [57] G. Alici, T. Canty, R. Mutlu, W. Hu, and V. Sencadas, “Modeling and Experimental Evaluation of Bending Behavior of Soft Pneumatic Actuators Made of Discrete Actuation Chambers,” Soft Robotics, Vol.5, No.1, 2018. https://doi.org/10.1089/soro.2016.0052

- [58] M. Schaffner, J. A. Faber, L. Pianegonda, P. A. Rühs, F. Coulter, and A. R. Studart, “3D Printing of Robotic Soft Actuators with Programmable Bioinspired Architectures,” Nature Communications, Vol.9, Article No.878, 2018. https://doi.org/10.1038/s41467-018-03216-w

- [59] Y. Yang, Y. Chen, Y. Li, M. Z. Q. Chen, and Y. Wei, “Bioinspired Robotic Fingers Based on Pneumatic Actuator and 3D Printing of Smart Material,” Soft Robotics, Vol.4, No.2, pp. 6221-6226, 2017. https://doi.org/10.1089/soro.2016.0034

- [60] J. Shintake, H. Sonar, E. Piskarev, J. Paik, and D. Floreano, “Soft Pneumatic Gelatin Actuator for Edible Robotics,” 2017 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 6222-6226, 2017. https://doi.org/10.1109/IROS.2017.8206525

- [61] K. Tadakuma, H. Komatsu, M. Fujita, A. Nomura, E. Takane, and S. Tadokoro, “Omnidirectional Expanding Torus Mechanism for Edible Robotics,” Proc. of JSME Annual Conf. on Robotics and Mechatronics, Vol.2017, 2017 (in Japanese). https://doi.org/10.1299/jsmermd.2017.2A1-A09

- [62] L. D. Chambers, J. Winfield, I. Ieropoulos, and J. Rossiter, “Biodegradable and Edible Gelatin Actuators for Use as Artificial Muscles,” Electroactive Polymer Actuators and Devices (EAPAD) 2014, Vol.9056, 2014.

- [63] D. G. Caldwell, G. A. Medrano-Cerda, and M. Goodwin, “Control of Pneumatic Muscle Actuators,” IEEE Control Systems Magazine, Vol.15, Issue 1, pp. 40-48, 1995. https://doi.org/10.1109/37.341863

- [64] K. Balasubramanian and K. S. Rattan, “Feedforward Control of a Non-Linear Pneumatic Muscle System Using Fuzzy Logic,” The 12th IEEE Int. Conf. on Fuzzy Systems, Vol.1, pp. 272-277, 2003. https://doi.org/10.1109/FUZZ.2003.1209374

- [65] C.-P. Chou and B. Hannaford, “Static and Dynamic Characteristics of McKibben Pneumatic Artificial Muscles,” Proc. of the 1994 IEEE Int. Conf. on Robotics and Automation, Vol.1, pp. 281-286, 1994. https://doi.org/10.1109/ROBOT.1994.350977

- [66] N. S. Usevitch, A. M. Okamura, and E. W. Hawkes, “APAM: Antagonistic Pneumatic Artificial Muscle,” 2018 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 1539-1556, 2018. https://doi.org/10.1109/ICRA.2018.8460881

- [67] H. Maeda, H. Nagai, H. Saito, and T. Nakamura, “Position and Compliance Control of an Artificial Muscle Manipulator Using a Mechanical Equilibrium Model,” 34th Annual Conf. of IEEE Industrial Electronics, pp. 3431-3436, 2008. https://doi.org/10.1109/IECON.2008.4758512

- [68] A. Kojima, M. Okui, I. Hisamichi, T. Tsuji, and T. Nakamura, “Straight-Fiber-Type Artificial Muscle Deformation Under Pressurization,” IEEE Robotics and Automation Letters, Vol.4, Issue 3, pp. 2592-2598, 2019. https://doi.org/10.1109/LRA.2019.2902016

- [69] W. Xiao, D. Hu, W. Chen, G. Yang, and X. Han, “Design, Characterization and Optimization of Multi-directional Bending Pneumatic Artificial Muscles,” J. of Bionic Engineering, Vol.18, pp. 1358-1368, 2021. https://doi.org/10.1007/s42235-021-00077-w

- [70] K. Suzumori, S. Iikura, and H. Tanaka, “Applying a Flexible Microactuator to Robotic Mechanisms,” IEEE Control Systems Magazine, Vol.12, Issue 1, pp. 21-27, 1992. https://doi.org/10.1109/37.120448

- [71] J. Zhou, S. Chen, and Z. Wang, “A Soft-Robotic Gripper With Enhanced Object Adaptation and Grasping Reliability,” IEEE Robotics and Automation Letters, Vol.2, Issue 4, pp. 2287-2293, 2017. https://doi.org/10.1109/LRA.2017.2716445

- [72] Sachin, Z. Wang, T. Matsuno, and S. Hirai, “Analytical Modeling of a Membrane-Based Pneumatic Soft Gripper,” IEEE Robotics and Automation Letters, Vol.7, Issue 4, pp. 10359-10366, 2022. https://doi.org/10.1109/LRA.2022.3183794

- [73] B. S. Homberg, R. K. Katzschmann, M. R. Dogar, and D. Rus, “Haptic Identification of Objects Using a Modular Soft Robotic Gripper,” Proc. of the 2015 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 1698-1705, 2015. https://doi.org/10.1109/IROS.2015.7353596

- [74] M. Ishii, K. Yamamoto, and K. Hyodo, “Stand-Alone Wearable Power Assist Suit – Development and Availability –,” J. Robot. Mechatron., Vol.17, No.5, pp. 575-583, 2005. https://doi.org/10.20965/jrm.2005.p0575

- [75] H. Kobayashi, T. Matsushita, Y. Ishida, and K. Kokuchi, “New Robot Technology Concept Applicable to Human Physical Support – The Concept and Possibility of the Muscle Suit (Wearable Muscular Support Apparatus) –,” J. Robot. Mechatron., Vol.14, No.1, pp. 46-53, 2002. https://doi.org/10.20965/jrm.2002.p0046

- [76] Y. Muramatsu, H. Kobayashi, Y. Sato, H. Jiaou, T. Hashimoto, and H. Kobayashi, “Quantitative Performance Analysis of Exoskeleton Augmenting Devices – Muscle Suit – for Manual Worker,” Int. J. Automation Technol., Vol.5, No.4, pp. 559-567, 2011. https://doi.org/10.20965/ijat.2011.p0559

- [77] H. K. Yap, J. H. Lim, F. Nasrallah, J. C. H. Goh, and R. C. H. Yeow, “A Soft Exoskeleton for Hand Assistive and Rehabilitation Application Using Pneumatic Actuators With Variable Stiffness,” 2015 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 4967-4972, 2015. https://doi.org/10.1109/ICRA.2015.7139889

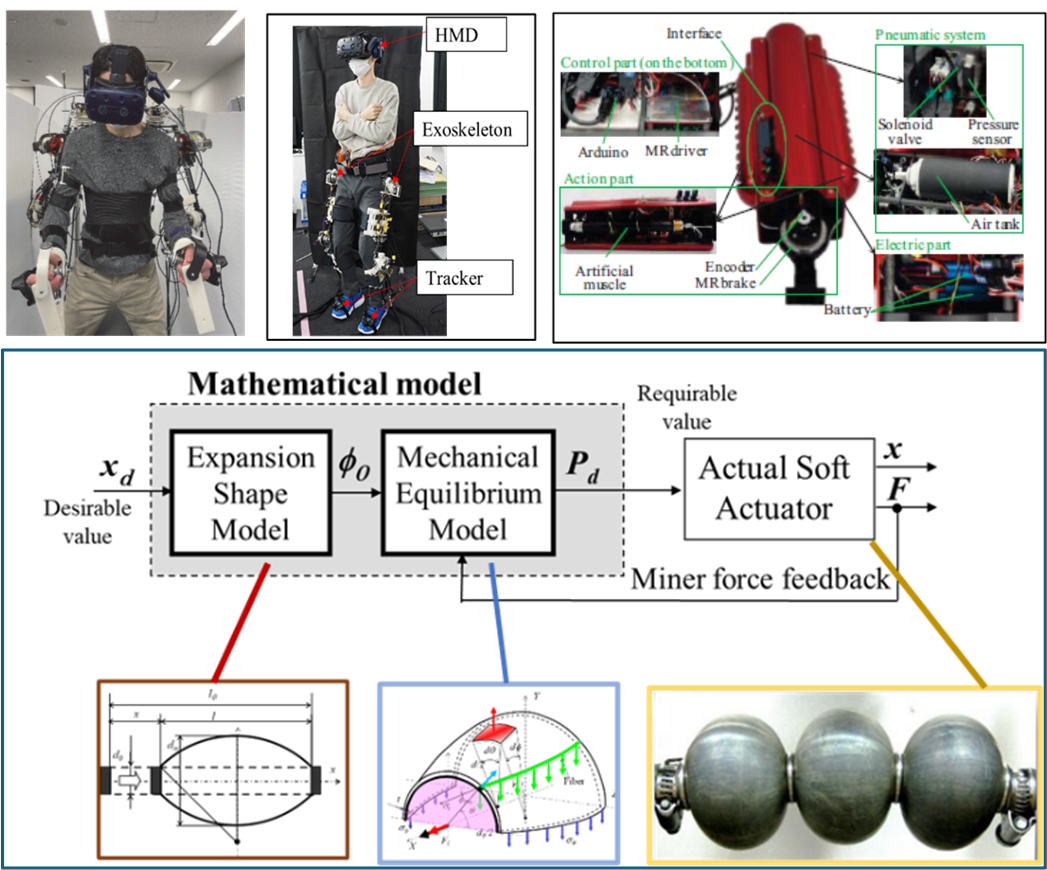

- [78] R. Sawahashi, J. Komatsu, R. Nishihama, M. Okui, and T. Nakamura, “Development of a Bimanual Wearable Force Feedback Device with Pneumatic Artificial Muscles, MR Fluid Brakes and Sensibility Evaluation Based on Pushing Motion,” J. Robot. Mechatron., Vol.35, No.1, pp. 180-193, 2023. https://doi.org/10.20965/jrm.2023.p0180

- [79] R. Sawahashi, T. Masuda, T. Shimizu, R. Nishihama, M. Okui, and T. Nakamura, “Presentation of Sensation of Knee Movement in Water With a Lower Limb Exoskeleton Using Magnetorheological Fluid Brakes,” 18th Int. Conf. on Electrorheological Fluids and Magnetorheological Suspensions (ERMR2023), 2023.

- [80] K. Machida, S. Kimura, R. Suzuki, K. Yokoyama, M. Okui, and T. Nakamura, “Variable Viscoelastic Joint Module with Built-in Pneumatic Power Source,” Proc. of the 2020 IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics (AIM), pp. 1048-1055, 2020. https://doi.org/10.1109/AIM43001.2020.9158861

- [81] M. Kubota and T. Noritsugu, “Development of In-Pipe Mobile Robot Using Pneumatic Soft-Actuator,” Proc. of the JFPS Int. Symp. Fluid Power, Vol.1999, No.4, pp. 195-200, 1999. https://doi.org/10.5739/isfp.1999.195

- [82] N. Saga and T. Nakamura, “Development of a Peristaltic Crawling Robot Using Magnetic Fluid on the Basis of the Locomotion Mechanism of the Earthworm,” Smart Materials and Structures, Vol.13, No.3, pp. 566-569, 2004. https://doi.org/10.1088/0964-1726/13/3/016

- [83] E. V. Mangan, D. A. Kingsley, R. D. Quinn, and H. J. Chiel, “Development of a Peristaltic Endoscope,” Proc. 2002 IEEE Int. Conf. on Robotics and Automation, Vol.1, pp. 347-352, 2002. https://doi.org/10.1109/ROBOT.2002.1013385

- [84] Y. Hidaka, T. Nakamura, and Y. Hori, “Peristaltic Crawling Robot With Artificial Rubber Muscles for Large Intestine Endoscopy,” Proc. of 12th Int. Conf. on Climbing and Walking Robot (CLAWAR2009), pp. 225-232, 2009. https://doi.org/10.1142/9789814291279_0030

- [85] Q. Zhangm, H. Fang, and J. Xu, “Yoshimura-origami Based Earthworm-Like Robot With 3-dimensional Locomotion Capability,” Frontiers in Robotics and AI, Vol.8, Article No.738214, 2021. https://doi.org/10.3389/frobt.2021.738214

- [86] M. Ikeuchi, T. Nakamura, and D. Matsubara, “Development of an In-Pipe Inspection Robot for Narrow Pipes and Elbows Using Pneumatic Artificial Muscles,” 2012 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 926-931, 2012. https://doi.org/10.1109/IROS.2012.6385925

- [87] K. Isaka, K. Tsumura, T. Watanabe, W. Toyama, M. Sugesawa, Y. Yamada, H. Yoshida, and T. Nakamura, “Development of Underwater Drilling Robot Based on Earthworm Locomotion,” IEEE Access, Vol.7, pp. 103127-103141, 2019. https://doi.org/10.1109/ACCESS.2019.2930994

- [88] T. Umedachi, V. Vikas, and B. A. Trimmer, “Highly Deformable 3-D Printed Soft Robot Generating Inching and Crawling Locomotions With Variable Friction Legs,” 2013 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 4590-4595, 2013. https://doi.org/10.1109/IROS.2013.6697016

- [89] M. Watanabe and H. Tsukagoshi, “Soft Sheet Actuator Generating Traveling Waves Inspired by Gastropod’s Locomotion,” 2017 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 602-607, 2017. https://doi.org/10.1109/ICRA.2017.7989074

- [90] S. Wakimoto, J. Nakajima, M. Takata, T. Kanda, and K. Suzumori, “A Micro Snake-Like Robot for Small Pipe Inspection,” Proc. of 2003 Int. Symp. on Micromechatronics and Human Science, pp. 303-308, 2003. https://doi.org/10.1109/MHS.2003.1249959

- [91] X. Qi, H. Shi, T. Pinto, and X. Tan, “A Novel Pneumatic Soft Snake Robot Using Traveling-Wave Locomotion in Constrained Environments,” IEEE Robotics and Automation Letters, Vol.5, Issue 2, pp. 1610-1617, 2020. https://doi.org/10.1109/LRA.2020.2969923

- [92] K. Suzumori, S. Endo, T. Kanda, N. Kato, and H. Suzuki, “A Bending Pneumatic Rubber Actuator Realizing Soft-bodied Manta Swimming Robot,” Proc. of the 2007 IEEE Int. Conf. on Robotics and Automation, pp. 4975-4980, 2007. https://doi.org/10.1109/ROBOT.2007.364246

- [93] H. Hirai, K. Matsui, T. Iimura, K. Mitsumori, and F. Miyazaki, “Modular Control of Limb Kinematics During Human Walking,” Proc. of the 2010 3rd IEEE RAS & EMBS Int. Conf. on Biomedical Robotics and Biomechatronics, pp. 716-720, 2010. https://doi.org/10.1109/BIOROB.2010.5628042

- [94] B.-S. Kang, C. S. Kothera, B. K. S. Woods, and N. M. Wereley, ”Dynamic Modeling of McKibben Pneumatic Artificial Muscles for Antagonistic Actuation,” 2009 IEEE Int. Conf. on Robotics and Automation, pp. 182-187, 2009. https://doi.org/10.1109/ROBOT.2009.5152280

- [95] Y. Midorikawa and T. Nakamura, “Variable Rheological Joints Using an Artificial Muscle Soft Actuator and Magneto-Rheological Fluids Brake,” M. Xie, Y. Xiong, C. Xiong, H. Liu, and Z. Hu (Eds.), “Intelligent Robotics and Applications. ICIRA 2009. Lecture Notes in Computer Science,” Vol.5928, pp. 504-514, Springer, 2009.

- [96] M. Okui, S. Iikawa, Y. Yamada, and T. Nakamura, “Variable Viscoelastic Joint System and Its Application to Exoskeleton,” Proc. of 2017 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 3897-3902, 2017. https://doi.org/10.1109/IROS.2017.8206242

- [97] Q. Guan, J. Sun, Y. Liu, N. M. Wereley, and J. Leng, “Novel Bending and Helical Extensile/Contractile Pneumatic Artificial Muscles Inspired by Elephant Trunk,” Soft Robotics, Vol.7, No.5, pp. 597-614, 2020. https://doi.org/10.1089/soro.2019.0079

- [98] K. Ma, X. Chen, J. Zhang, Z. Xie, J. Wu, and J. Zhang, “Inspired by Physical Intelligence of an Elephant Trunk: Biomimetic Soft Robot With Pre-Programmable Localized Stiffness,” IEEE Robotics and Automation Letters, Vol.8, Issue 5, pp. 2898-2905, 2023. https://doi.org/10.1109/LRA.2023.3256922

- [99] M. Takeichi, K. Suzumori, G. Endo, and H. Nabae, “Development of Giacometti Arm With Balloon Body,” IEEE Robotics and Automation Letters, Vol.2, No.2, pp. 951-957, 2017. https://doi.org/10.1109/LRA.2017.2655111

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.