Paper:

Research on Debris Removal Robot

Yohei Kobayashi*, Kenta Morita*, and Shigekazu Suzuki**

*National Institute of Technology, Maizuru College

234 Shiroya, Maizuru, Kyoto 625-8511, Japan

**National Institute of Technology, Fukushima College

30 Nagao, Kamiarakawa, Taira, Iwaki, Fukushima 970-8034, Japan

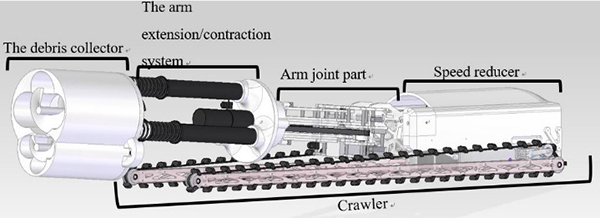

This study developed a debris removal robot for the Fukushima Daiichi Nuclear Power Plant. The creative robot contest for decommissioning the nuclear reactors of the Fukushima Daiichi Nuclear Power Station is an annual competition based on problem-based learning. It aims to stimulate students’ interest in decommissioning nuclear reactors while simultaneously imparting problem-solving skills. The development of our debris removal robot started with this contest. The proposed robot can travel in a pipe, has a 3 m telescopic arm, and is equipped with a debris removal device known as a spiral catcher. This report provides an overview of this robot. We expect that complex robot development will be achieved by putting forth several ideas from various fields and fostering advanced problem-solving skills by encouraging students to address difficult tasks. Therefore, we successfully fostered the social implementation skills of students and developed a debris removal robot.

The developed debris retrieval robot

- [1] K. Morita and Y. Kobayashi, “Development of debris extraction robot for Fukushima Daiichi Nuclear Power Station,” Maizuru National College of Technology 2018, National College of Technology 4.0 Initiative Project Results Report, pp. 5-10, 2019.

- [2] O. Seki, “Current Status of D&R for Fuel Debris Retrieval to Proceed with Decommissioning of the Fukushima Daiichi NPS – Outline of D&R Conducted by International Research Institute for Nuclear Decommissioning (IRID) –,” Decommissioning Technical Report, J. of the RANDEC, pp. 29-45, 2017 (in Japanese).

- [3] S. Suzuki, “Human Resource Development Through the Creative Robot Contest for Decommissioning,” J. of the Robotics Society of Japan, Vol.36, No.7, pp. 483-486, 2018 (in Japanese).

- [4] T. Doi and S. Suzuki, “Summary of the third HIRO creative RoboCon and characteristics of the robots participating in that – Application of high mobility mechanism with passive wheels unit –,” Proc. of JSME Annual Conf. on Robotics and Mechatronics (Robomec), 2P2-M07, 2019.

- [5] S. Kino, E. Takada, S. Suzuki, Y. Ohta, and T. Suzuki, “Education for human resource development in the nuclear field in National Institute of Technology,” J. of the Atomic Energy Society of Japan, Vol.57, No.9, pp. 612-615, 2015 (in Japanese).

- [6] H. Asama, “Remote technology for decommissioning of Fukushima Daiichi Nuclear Power Station,” J. of the Atomic Energy Society of Japan, Vol.62, No.3, pp. 125-126, 2020.

- [7] S. Onitsuka, “Present status of Fukushima Daiichi Nuclear power plant decommissioning,” J. of the Atomic Energy Society of Japan, Vol.62, No.3, pp. 121-124, 2020 (in Japanese).

- [8] R. Fukui, G. Kanayama, Y. Kato, R. Takahashi, and S. Warisawa, “Development of an Intersection Module for a Modularized Rail Structure – Implementation of Compliant Mechanisms for a Replacing Task of Movable Parts –,” J. Robot. Mechatron., Vol.30, No.3, pp. 467-476, 2018.

- [9] R. Fukui, K. Kawae, Y. Kato, and M. Nakao, “Rail Structure Supporting Mechanism Using Foamable Resin for Pillar Expansion, Anchoring, and Fixation,” J. Robot. Mechatron., Vol.28, No.2, pp. 129-137, 2016.

- [10] Y. Kaji, J. Kawata, and S. Fujisawa, “Educational Effect of Participation in Robot Competition on Experience-Based Learning,” J. Robot. Mechatron., Vol.31, No.3, pp. 383-390, 2019.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.