Paper:

Viscosity Control of Magnetorheological Fluid by Power Saving Magnetizing Mechanism Using Movement of Permanent Magnet

Jumpei Kawasaki*, Yuki Nakamura*, and Yasukazu Sato**

*Department of Mechanical Engineering, Graduate School of Engineering, Yokohama National University

79-5 Tokiwadai, Hodogaya-ku, Yokohama, Kanagawa 240-8501, Japan

**Department of Mechanical Engineering, Faculty of Engineering, Yokohama National University

79-5 Tokiwadai, Hodogaya-ku, Yokohama, Kanagawa 240-8501, Japan

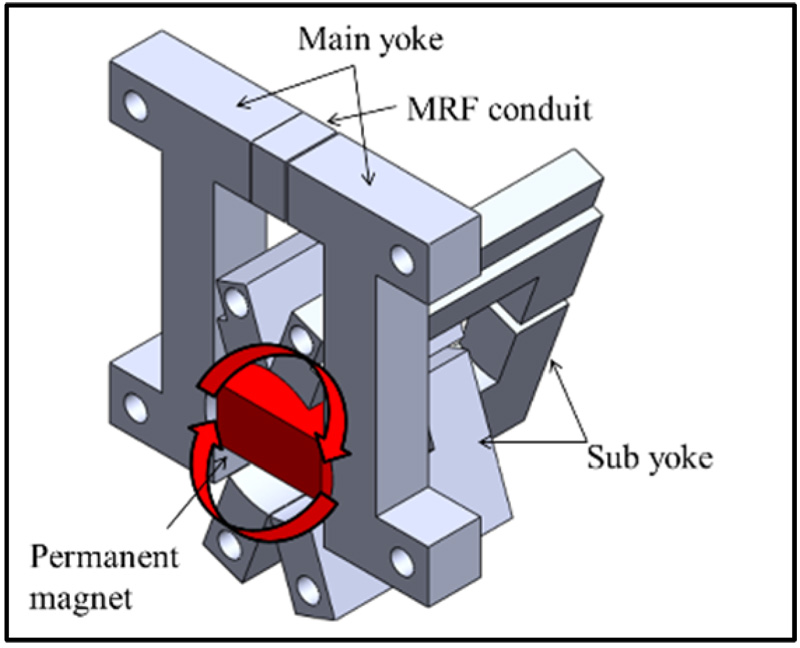

Generally, the magnetic field applied to a magnetorheological fluid (MRF) is generated by electromagnets. Electromagnets consume electric power during MRF magnetization, which is an issue. In this study, we examine two kinds of magnetizing mechanism using a permanent magnet, instead of electromagnets, to save electric power and generate a magnetic field on the MRF. One mechanism linearly moves the permanent magnet into the magnetic circuit composed of yokes. The magnetic field intensity on the MRF is then controlled by changing the overlap between the magnet and the yokes. The other mechanism rotates a permanent magnet in the magnetic circuit. The magnetic field intensity on the MRF is then controlled by changing the relative angular position between the magnet and the yokes. These two mechanisms normally generate force or torque on the magnet toward a magnetically stable position concerning the magnet, and the force or torque causes power consumption to hold and move the magnet. We design herein special magnetic circuits and a cancelation mechanism for the force or torque that drastically reduce the power consumption during the MRF magnetization compared with an electromagnet-type magnetizing device.

MRF control using rotary permanent magnet

- [1] T. Fujita and K. Shimada, “Characteristics and applications of magnetorheological fluids,” J. of the Magnetics Society of Japan, Vol.27, No.3, pp. 91-100, 2003.

- [2] N. Takesue, J. Furusho, and Y. Kiyota, “Fast response MR-Fluid actuator,” JSME Int. J., Series C, Vol.47, No.3, pp. 783-791, 2004.

- [3] T. Murakami, M. Sakai, and M. Nakano, “Study on the development of passive MR damper with displacement-dependent damping characteristics,” J. of Fluid Science and Technology, Vol.5, No.2, pp. 86-97, 2010.

- [4] J. D. Carlson, D. M. Catanzarite, and K. A. St. Clair, “Commercial magneto-rheological fluid devices,” Proc. of the 5th Int. Conf. on Electro-Rheological Fluids, Magneto-Rheological Suspensions and Associated Technology, pp. 20-28, 1995.

- [5] S. J. McManus et al., “Evaluation of vibration and shock attenuation performance of suspension seat with a semi-active magnetorheological fluid damper,” J. of Sound and Vibration, Vol.253, No.1, pp. 313-327, 2002.

- [6] S. W. Cho et al., “Smart passive system based on magnetorheological damper,” Smart Material Structure, Vol.14, pp. 707-714, 2005.

- [7] T. Kikuchi et al., “Development of compact MR fluid clutch for human-friendly actuator,” Advanced Robotics, Vol.24, No.10, pp. 1489-1502, 2010.

- [8] G. Yang, B. F. Spencer Jr., J. D. Carlson, and M. K. Sain, “Large scale MR fluid dampers: modeling and dynamic performance considerations,” Engineering Structures, Vol.24, pp. 309-323, 2002.

- [9] B. Kavlicoglu et al., “A semi-active, high torque, magnetorheological fluid limited slip differential clutch,” ASME J. of Vibration and Acoustics, Vol.128, No.10, pp. 604-610, 2006.

- [10] L. Peretti and M. Zigliotto, “A force feedback system for steer-by-wire applications based on low cost MR fluids design hints,” Power Electronics, Machines and Drivers, 2006 the 3rd IET Int. Conf., pp. 469-473, 2006.

- [11] K. Yoshida, Y. Jung, and S. Yokota, “A microvalve using MR fluid valve-body,” Trans. of the Japan Society of Mechanical Engineers, Series C, Vol.69, No.682, pp. 1633-1639, 2003.

- [12] J. Furusho and N. Takesue, “Research and Development of Functional Fluid Mechatronics, Rehabilitation Systems and Mechatronics of Flexible Drive Systems,” J. Robot. Mechatron., Vol.28, No.1, pp. 5-16, 2016.

- [13] J. Furusho and M. Haraguchi, “Development of Rehabilitation Systems for the Limbs Using Functional Fluids,” J. Robot. Mechatron., Vol.26, No.3, pp. 302-309, 2014.

- [14] Y. Sato and S. Umebara, “Power-saving magnetization for magnetorheological fluid control using a combination of permanent magnet and electromagnet,” IEEE Trans. on Magnetics, Vol.48, No.11, pp. 3521-3524, 2012.

- [15] Y. Sato and S. Umebara, “Digital/analog hybrid magnetization of magnetorheological fluids for expansion of their controllable viscosity range,” IEEE Trans. on Magnetics Vol.48, No.11, pp. 3760-3763, 2012.

- [16] Y. Sato, “Power-saving magnetizing device for magnetorheological fluid control using permanent magnet,” IEEE Trans. on Magnetics, Vol.50, No.11, 4601004, 2014.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.