Paper:

Investigation of Accumulator Parameters for a Novel Hybrid Architecture

Seiji Hijikata*, Kazuhisa Ito**, and Hubertus Murrenhoff*

*Institute for Fluid Power Drives and Systems (ifas), RWTH Aachen University

Campus-Boulevard 30, Aachen 52074, Germany

**Department of Machinery and Control Systems, College of Systems Engineering and Science,

Shibaura Institute of Technology

307 Fukasaku, Minuma-ku, Saitama 337-8570, Japan

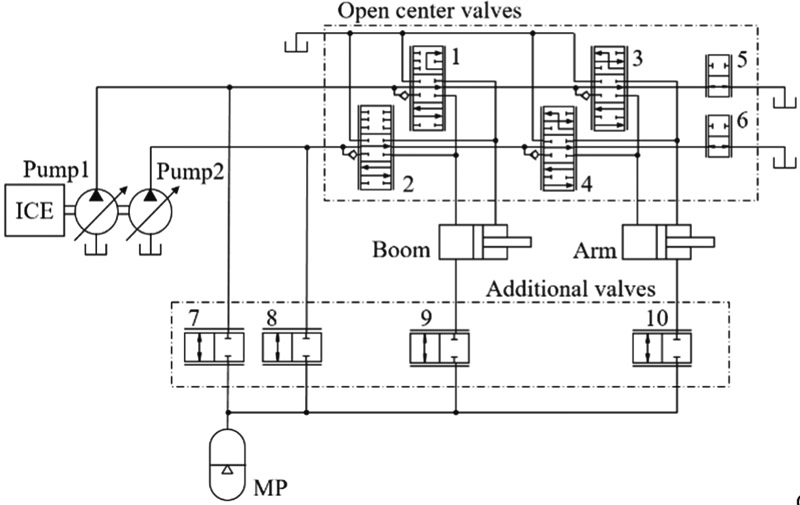

An open center system (OC-System), which is one of the major hydraulic architectures for excavators, has been improved in the world to reduce fuel consumption for global environment conservation and lower operating costs. However, the total system efficiency, including the internal combustion engine (ICE), has not been thoroughly considered. In contrast, a constant pressure system (CP-System) enabling the engine to be driven optimally is developed, but is not accepted in the industry owing to the complexity of the required components. Thus, in this research, a hybrid system combining an OC-System with a CP-System is proposed to improve the total system efficiency. An accumulator, which is used to provide flow rate to actuators, is essential for the new hybrid system, and it is vital to consider the nominal gas volume and pressure level for the accumulator in terms of energy savings and initial cost. Therefore, the influences of accumulator volume and pressure level are discussed in this paper.

Hydraulic circuit for new hybrid system

- [1] S. Gessi, M. Martelli, and E. Tonini, “A Survey on Negative Control Architectures for Hydraulic Excavators,” Proc. of ASME/BATH Symp. on Fluid Power and Motion Control, Chicago, 2015.

- [2] E. Busquets and M. Ivantysynova, “Toward Supervisory-Level Control for the Energy Consumption and Performance Optimization of Displacement-Controlled Hydraulic Hybrid Machines,” 10th Int. Fluid Power Conf., Dresden, Germany, 2016.

- [3] J. Siebert and M. Geimer, “Reduction of System Inherent Pressure Losses at Pressure Compensators of Hydraulic Load Sensing Systems,” 10th Int. Fluid Power Conf., Dresden, Germany, 2016.

- [4] C. Joo and M. Stangl, “Application of Power Regenerative Boom system to excavator,” Proc. of 10th Int. Conf. on Fluid Power, Dresden, 2016.

- [5] F. Bauer, D. Feld, and C. Stauch, “Increased energy efficiency of hydraulic hybrid drives by means of a multi-chamber accumulator,” Proc. of 10th Int. Conf. on Fluid Power, Dresden, 2016.

- [6] Y. Oshima, T. Kinoshita, K. Koiwai, T. Yamamoto, T. Nanjo, Y. Yamazaki, and Y. Fujimoto, “Data-Driven Torque Controller for a Hydraulic Excavator,” J. Robot. Mechatron., Vol.28, No.5, pp. 752-758, 2016.

- [7] B. Eriksson, V. Bhaskar, and R. Gomm, “Energy Efficiency Comparison of Electric-Hydraulic HybridWork Implements Systems,” The 15th Scandinavian Int. Conf. on Fluid Power (SICFP’17), Linköping, Sweden, 2017.

- [8] M. Wydra, M. Geimer and B. Weiss, “An Approach to Combine an Independent Metering System with an Electro-Hydraulic Flow-on-Demand Hybrid-System,” The 15th Scandinavian Int. Conf. on Fluid Power (SICFP’17), Linköping, Sweden, 2017.

- [9] P. Marani and M. Martelli, “Energy and Control Characteristics of a Novel Meter Out Hydraulic System for Mobile Applications,” ASME/BATH 2017 Symp. on Fluid Power & Motion Control, Sarasota, Florida, USA, 2017.

- [10] Q. Zhong, B. Zhang, M. Niu, H. Haocen, and H. Yang, “Research on Dynamic Performance of Independent Metering Control System,” ASME/BATH 2017 Symp. on Fluid Power & Motion Control, Sarasota, Florida, USA, 2017.

- [11] L. Xia, L. Quan, B. Zhao, C. Wang, and W. She, “Research of hydraulic – gas combined draiving system for hydraulic excavator boom,” The 10th JFPS Int. Symp. of Fluid Power, 2017.

- [12] H. Kwon, N. Keller, and M. Ivantysynova, “Thermal Management of Open and Closed Circuit Hydraulic Hybrids – A Comparison Study,” 11th Int. Fluid Power Conf., Aachen, Germany, 2018.

- [13] U. Lenzgeiger, U. Maier, and P. Schmuttermair, “Electronic Load-Sensing for Tractors,” 11th Int. Fluid Power Conf., Aachen, Germany, 2018.

- [14] S. Itagaki, H. T. Phan, and Y. Sato, “Study on high efficiency power transmission in servomotor-driven hydraulic system,” The Proc. on Spring Conf. of Japan Fluid Power System Society, pp. 45-47, 2019 (in Japanese).

- [15] M. Ito, Y. Funahara, S. Saiki, Y. Yamazaki, and Y. Kurita, “Development of a Cross-Platform Cockpit for Simulated and Tele-Operated Excavators,” J. Robot. Mechatron., Vol.31, No.2, pp. 231-239, 2019.

- [16] T. Nakamura, K. Nakamura, Y. Okano, K. Ishikawa, K. Sato, H. Azuma, M. Kanehama, and Y. Kajita, “Hydraulic Drive Device for Working Machine,” Japan Patent WO 2012/157705 A1; JP 2012-241803A, Oct. 12, 2012.

- [17] M. Vukovic, S. Sgro, and H. Murrenhoff, “STEAM – A Mobile Hydraulic System with Engine Integration,” ASME/BATH 2013 Symp. on Fluid Power & Motion Control, Sarasota, Florida, USA, 2013.

- [18] M. Vukovic, R. Leifeld, and H. Murrenhoff, “STEAM – Hydraulic Design for Engine Integration,” O+P Ölhydraulik und und Pneumatik, Vol.59, No.1, 2015.

- [19] M. Vukovic, “Hydraulic Hybrid systems for excavators,” Ph.D. thesis, RWTH Aachen University, 2017.

- [20] K. Sugimura, “Novel hydraulic hybrid system for excavators,” Ph.D. thesis, RWTH Aachen University, 2018.

- [21] S. Hijikata, P. Weishaar, K. Sugimura, K. Schmitz, and H. Murrenhoff, “A hydraulic hybrid architecture combining an open center with a constant pressure system for excavators,” 11th Int. Fluid Power Conf., Aachen, Germany, 2018.

- [22] S. Hijikata, P. Weishaar, R. Leifeld, and K. Schmitz, “Efficiency for a hydraulic hybrid architecture of excavators,” MM Science J., doi: 10.17973/MMSJ.2018_10_201831, October 2018.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.