Paper:

Gravity Compensation Modular Robot: Proposal and Prototyping

Yukio Morooka and Ikuo Mizuuchi

Tokyo University of Agriculture and Technology

2-24-16 Naka-cho, Koganei-shi, Tokyo 184-8588, Japan

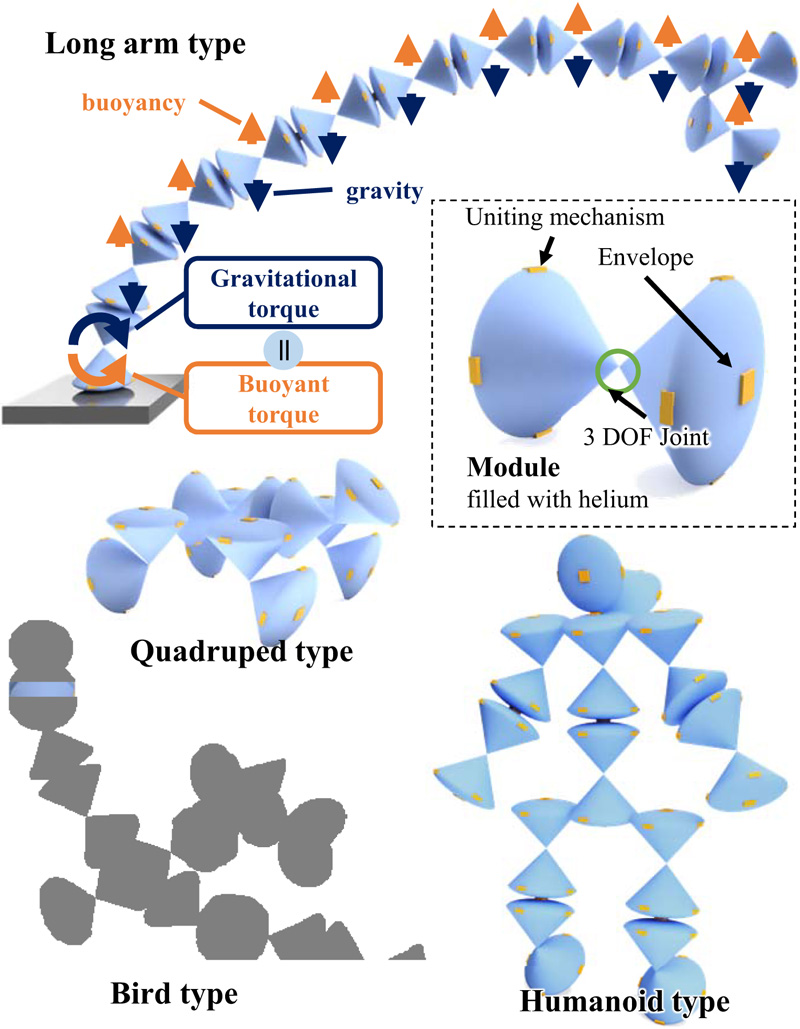

If a robot system can take various shapes, then it can play various roles, such as humanoid, dog robot, and robot arm. A modular robot is a robot system in which robots are configured using multiple modules, and it is possible to configure robots of other shapes by varying the combinations of the modules. In conventional modular robots, the shape is restricted by gravity, and configurable shapes are limited. In this study, we propose a gravity compensation modular robot to solve this problem. This paper describes the design and prototyping of the gravity compensation modular robot, and provides examples of robot shapes configured using the gravity compensation modules and motion experiments of the robots. In the experiments, there were motions that the robots could perform and could not perform. We considered the lack in the gravity compensation level and module rigidity as the main factor of the failures. This paper also discusses the solutions to these problems.

Concept of gravity compensation modular robot

- [1] J. Feczko, M. Manka, P. Krol, M. Giergiel, T. Uhl, and A. Pietrzyk, “Review of the modular self reconfigurable robotic systems,” 2015 10th Int. Workshop on Robot Motion and Control (RoMoCo), pp. 182-187, 2015.

- [2] T. Fukuda and S. Nakagawa, “Approach to the dynamically reconfigurable robotic system,” J. of Intelligent and Robotics System, Vol.1, No.1, pp. 55-72, 1988.

- [3] T. Matsumaru, “Design disquisition on modular robot systems,” J. Robot. Mechatron., Vol.8, No.5, pp. 408-419, 1996.

- [4] E. Yoshida, S. Murata, S. Kokaji, K. Tomita, and H. Kurokawa, “Micro self-reconfigurable modular robot using shape memory alloy,” J. Robot. Mechatron., Vol.13, No.2, pp. 212-219, 2001.

- [5] H. Kurokawa, A. Kamimura, E. Yoshida, K. Tomita, S. Kokaji, and S. Murata, “M-TRAN II: metamorphosis from a four-legged walker to a caterpillar,” Proc. 2003 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS2003), Vol.3, pp. 2454-2459, October 2003.

- [6] M. W. Jorgensen, E. H. Ostergaard, and H. H. Lund, “Modular ATRON: Modules for a self-reconfigurable robot,” Proc. of IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS2004), Vol.2, pp. 2068-2073, 2004.

- [7] A. Lyder, R. F. M. Garcia, and K. Stoy, “Mechanical design of odin, an extendable heterogeneous deformable modular robot,” Proc. of IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS2008), pp. 883-888, 2008.

- [8] K. Gilpin, K. Kotay, D. Rus, and I. Vassilescu, “Miche: Modular shape formation by self-dissasembly,” Proc. 2007 IEEE Int. Conf. on Robotics and Automation, pp. 2241-2247, April 2007.

- [9] K. Gilpin, A. Knaian, and D. Rus, “Robot Pebbles: One centimeter modules for programmable matter through self-disassembly,” Proc. of 2010 IEEE Int. Conf. on Robotics and Automation, pp. 2485-2492, 2010.

- [10] T. Taira and N. Yamasaki, “Design and implementation of the reconfiguration mechanism for a modular humanoid robot,” J. Robot. Mechatron., Vol.18, No.3, pp. 286-298, 2006.

- [11] M. Yim, K. Roufas, D. Duff, Y. Zhang, C. Eldershaw, and S. Homans, “Modular reconfigurable robots in space applications,” Autonomous Robots, Vol.14, No.2, pp. 225-237, 2003.

- [12] N. Ulrich and V. Kumar, “Passive mechanical gravity compensation for robot manipulators,” Proc. 1991 IEEE Int. Conf. on Robotics and Automation, Vol.2, pp. 1536-1541, April 1991.

- [13] J. M. Hervé, “Design of Spring Mechanisms for Balancing the Weight of Robots,” A. Morecki, G. Bianchi, K. Kędzior (Eds.), “RoManSy 6,” Springer, pp. 564-567, 1987.

- [14] M. Takeichi, K. Suzumori, G. Endo, and H. Nabae, “Development of a 20-m-long Giacometti arm with balloon body based on kinematic model with air resistance,” Proc. of 2017 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS2017), pp. 2710-2716, September 2017.

- [15] S. Ghassemi and D. Hong, “Feasibility study of a novel robotic system BALLU: Buoyancy assisted lightweight legged unit,” Proc. of IEEE-RAS 16th Int. Conf. on Humanoid Robots (Humanoids 2016), pp. 144-144, November 2016.

- [16] R. Oung and R. D’Andrea, “The distributed flight array,” 2010 IEEE Int. Conf. on Robotics and Automation, pp. 601-607, May 2010.

- [17] M. E. Karagozler, B. Kirby, W. J. J. Lee, E. Marinelli, T. C. Ng, M. P. Weller, and S. C. Goldstein. “Ultralight modular robotic building blocks for the rapid deployment of planetary outposts,” Proc. of Revolutionary Aerospace Systems Concepts Academic Linkage (RASC-AL) Forum 2006, 2006.

- [18] N. Yamamoto and I. Mizuuchi, “Deciding shapes and motions of a robot based on personal preferences,” Proc. of the 27th IEEE Int. Symp. on Robot and Human Interactive Communication (ROMAN2018), pp. 1178-1184, 2018.

- [19] N. Takesue, T. Ikematsu, H. Murayama, and H. Fujimoto, “Design and prototype of variable gravity compensation mechanism (VGCM),” J. Robot. Mechatron., Vol.23, No.2, pp. 249-257, 2011.

- [20] Y. Kawahara, S. Hodges, B. S. Cook, C. Zhang, and G. Abowd, “Instant inkjet circuits: Lab-based inkjet printing to support rapid prototyping of ubicomp devices,” Proc. of the 2013 ACM Int. Joint Conf. on Pervasive and Ubiquitous Computing (UbiComp 2013), pp. 363-372, 2013. ≠wpage

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.