Research Paper:

Dual-Branch Residual Network for Enhanced Steel Plate Fault Detection

Hao Chen†

and Jiaxin Lu

and Jiaxin Lu

School of Information Engineering, Nantong Institute of Technology

211 Yongxing Road, Chongchuan District, Nantong, Jiangsu 226002, China

†Corresponding author

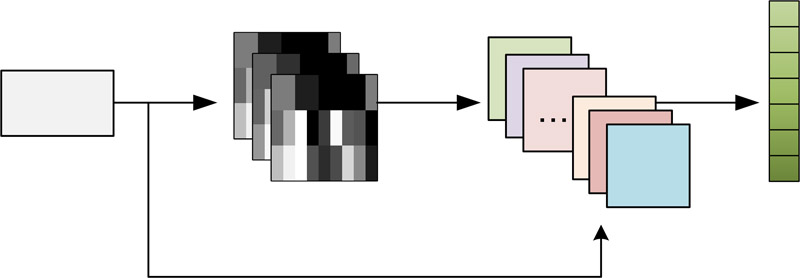

Steel plate fault detection plays a crucial role in industrial manufacturing. However, the inherent complexity of steel plate fault data and the redundancy of certain features pose significant challenges for effective feature extraction. To address these challenges, we propose a dual-branch residual network model (DRNM), which utilizes a two-branch architecture. The first branch processes the original data through a convolutional neural network to capture local feature details, and the second branch leverages feature mapping to extract the spatial relationships within the data. To enhance feature extraction depth and model performance, residual networks are integrated into both branches, allowing for deeper network training and the capture of richer feature representations. The proposed dual feature extraction mechanism significantly improves the model’s representational power and fault-detection accuracy. Experimental results on a public dataset demonstrate that DRNM achieves state-of-the-art performance, with average recall and F1 score of 90.11% and 90.79%, respectively, substantially outperforming existing methods.

Steel plate fault detection via DRNM

- [1] C. Zhang, J. Cui, J. Wu, and X. Zhang, “Attention mechanism and texture contextual information for steel plate defects detection,” J. of Intelligent Manufacturing, Vol.35, No.5, pp. 2193-2214, 2024. https://doi.org/10.1007/s10845-023-02149-6

- [2] G. Liu, M. Chu, R. Gong, and Z. Zheng, “Global attention module and cascade fusion network for steel surface defect detection,” Pattern Recognition, Vol.158, Article No.110979, 2025. https://doi.org/10.1016/j.patcog.2024.110979

- [3] I. D. Kordatos and P. Benardos, “Comparative analysis of machine learning algorithms for steel plate defect classification,” Int. J. of Mechatronics and Manufacturing Systems, Vol.15, No.4, pp. 246-263, 2022. https://doi.org/10.1504/IJMMS.2022.127211

- [4] M. Gao, Y. Wei, Z. Li, B. Huang, C. Zheng, and A. Mulati, “A survey of machine learning algorithms for defective steel plates classification,” Int. Conf. on Computing, Control and Industrial Engineering, pp. 467-476, 2024. https://doi.org/10.1007/978-981-97-6934-6_55

- [5] B. Ghasemkhani, R. Yilmaz, D. Birant, and R. A. Kut, “Logistic model tree forest for steel plates faults prediction,” Machines, Vol.11, No.7, Article No.679, 2023. https://doi.org/10.3390/machines11070679

- [6] A. Feyzio~glu and Y. S. Taspinar, “Detection of Defects in Rolled Stainless Steel Plates by Machine Learning Models,” Int. J. of Applied Mathematics Electronics and Computers, Vol.11, No.1, pp. 37-43, 2023. https://doi.org/10.18100/ijamec.1253191

- [7] Y. Zhou, J. Zhang, P. Ni, Q. Cao, and J. Hu, “A customised ConvNeXt-SCC network: Integrating improved principal component analysis with ConvNeXt to enhance tire crown defect detection,” Nondestructive Testing and Evaluation, pp. 1-29, 2024.

- [8] X. Yi, L. Dang, D. Yan, Y. Yang, and S. Dian, “Simulation Study on Defect Detection of Penstocks Based on Kernel Principal Component Analysis,” 2024 9th Int. Conf. on Automation, Control and Robotics Engineering, pp. 159-163, 2024. https://doi.org/10.1109/CACRE62362.2024.10635031

- [9] W. Deng, B. Ye, J. Bao, G. Huang, and J. Wu, “Classification and quantitative evaluation of eddy current based on kernel-PCA and ELM for defects in metal component,” Metals, Vol.9, No.2, Article No.155, 2019. https://doi.org/10.3390/met9020155

- [10] F. Nadir, B. Messaoud, and H. Elias, “Utilizing principal component analysis for the identification of gas turbine defects,” J. of Failure Analysis and Prevention, Vol.24, No.1, pp. 97-107, 2024. https://doi.org/10.1007/s11668-023-01817-2

- [11] B. Zhao, Y. Chen, X. Jia, and T. Ma, “Steel surface defect detection algorithm in complex background scenarios,” Measurement, Vol.237, Article No.115189, 2024. https://doi.org/10.1016/j.measurement.2024.115189

- [12] S. She, X. Zheng, T. Meng, K. Yu, and W. Yin, “Inspection of defects depth for stainless-steel sheets using four-coil excitation sensor and deep learning,” IEEE Trans. on Instrumentation and Measurement, Vol.72, pp. 1-10, 2023. https://doi.org/10.1109/TIM.2023.3267340

- [13] W. Cao, X. Sun, Z. Liu, Z. Chai, G. Bao, Y. Yu, and X. Chen ”The detection of PAUT pseudo defects in ultra-thick stainless-steel welds with a multimodal deep learning model,” Measurement, Vol.241, Article No.115662, 2025. https://doi.org/10.1016/j.measurement.2024.115662

- [14] L. Zhao, Y. Zhang, J. Duan, and J. Yu, “Cross-supervised contrastive learning domain adaptation network for steel defect segmentation,” Advanced Engineering Informatics, Vol.64, Article No.102964, 2025. https://doi.org/10.1016/j.aei.2024.102964

- [15] S. Farahmand-Tabar and T. A. Rashid, “Steel Plate fault detection using the fitness-dependent optimizer and neural networks,” Handbook of Formal Optimization, Springer Nature Singapore, pp. 1-19, 2024. https://doi.org/10.1007/978-981-19-8851-6_41-1

- [16] F. Zhang, L. Wang, and W. Ye, “Aluminum plate defect detection based on multilevel LSTM,” Chinese J. of Theoretical and Applied Mechanics, Vol.55, No.11, pp. 2566-2576, 2023. http://doi.org/10.6052/0459-1879-23-193

- [17] B. Tang, Z. K. Song, W. Sun, and X. D. Wang, “An end-to-end steel surface defect detection approach via Swin transformer,” IET Image Processing, Vol.17, No.5, pp. 1334-1345, 2023. https://doi.org/10.1049/ipr2.12715

- [18] L. Yang, X. Huang, Y. Ren, and Y. Huang, “Steel plate surface defect detection based on dataset enhancement and lightweight convolution neural network,” Machines, Vol.10, No.7, Article No.523, 2022. https://doi.org/10.3390/machines10070523

- [19] S. A. Vayghan, S. Teymouri, S. Etaati, J. Khoramdel, Y. Borhani, and E. Najafi, “Steel Surface Defect Detection and Segmentation using Deep Neural Networks,” Results in Engineering, Article No.103972, 2025. https://doi.org/10.1016/j.rineng.2025.103972

- [20] Z. Song, X. Huang, C. Ji, Y. Zhang, Z. Chao, and Y. Peng, “Cross-domain fine grained strip steel defect detection method based on semi-supervised learning and multi-head self attention coordination,” Computers and Electrical Engineering, Vol.121, Article No.109916, 2025. https://doi.org/10.1016/j.compeleceng.2024.109916

- [21] Y. Xia, Y. Lu, X. Jiang, and M. Xu, “Enhanced multiscale attentional feature fusion model for defect detection on steel surfaces,” Pattern Recognition Letters, Vol.188, pp. 15-21, 2025. https://doi.org/10.1016/j.patrec.2024.11.024

- [22] I. U. Khan, N. Aslam, M. Aboulnour, A. Bashamakh, F. Alghool, N. Alsuwayan, R. Alturaif, H. Gull, S. Z. Iqbal, and T. Hussain, “Deep Learning-Based Surface Defect Detection in Steel Products Using Convolutional Neural Networks,” Mathematical Modelling of Engineering Problems, Vol.11, No.11, pp. 3006-3014, 2024. https://doi.org/10.18280/mmep.111113

- [23] Y. Wang, X. Shen, K. Wu, and M. Huang, “Corrosion grade recognition for weathering steel plate based on a convolutional neural network,” Measurement Science and Technology, Vol.33, No.9, Article No.095014, 2022. https://doi.org/10.1088/1361-6501/ac7034

- [24] W. Zeng, J. Wang, P. Chen, Z. Zhong, G. Hu, and W. Bao, “Surface defect identification method for hot-rolled steel plates based on random data balancing and lightweight convolutional neural network,” Signal, Image and Video Processing, pp. 1-12, 2024.

- [25] S. Li, C. Wu, and N. Xiong, “Hybrid architecture based on CNN and transformer for strip steel surface defect classification,” Electronics, Vol.11, No.8, Article No.1200, 2022. https://doi.org/10.3390/electronics11081200

- [26] H. Özbay, İ. Özer, A. Dalcali, O. Çetin, and F. Temurtaş, “Sensorless Position Estimation in Electromagnetic Launchers Using Recurrent Neural Networks with Repeated k-Fold Cross-Validation,” Arabian J. for Science and Engineering, pp. 1-19, 2025. https://doi.org/10.1007/s13369-024-09905-7

- [27] M. M. Buscema, “The theory of independent judges,” Substance use & misuse, Vol.33, No.2, pp. 439-461, 1998. https://doi.org/10.3109/10826089809115875

- [28] Z. H. Wang, Y. F. Liu, T. Wang, J. G. Wang, Y .M. Liu, and Q. X. Huang, “Intelligent prediction model of mechanical properties of ultrathin niobium strips based on XGBoost ensemble learning algorithm,” Computational Materials Science, Vol.231, Article No.112579, 2024. https://doi.org/10.1016/j.commatsci.2023.112579

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.