Paper:

A Predicting Model for Near-Horizontal Directional Drilling Path Based on BP Neural Network in Underground Coal Mine

Hongchao Wei*,**, Ningping Yao*,**,†, Hongliang Tian*,**, Yafeng Yao*,**, Jinbao Zhang**, and Hao Li*,**

*China Coal Research Institute

No.5 Qingniangou East Road, Hepingli, Chaoyang District, Beijing 100013, China

**CCTEG Xi’an Research Institute

82 Jinye 1st Road, Gaoxin District, Xi’an, Shaanxi 710077, China

†Corresponding author

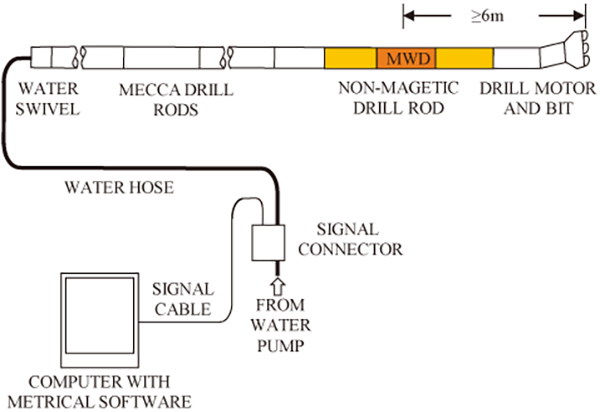

This study establishes a prediction model based on the back propagation (BP) neural network for controlling the underground directional drilling path in a coal mine. The four-layer BP neural network model chooses 11 trajectory parameters (dip angles and azimuths from 12 m after the measurement while drilling (MWD)) and two control parameters as inputs. Two parameters, the dip angle and azimuth at bit, are the outputs. Trained with data from 502 groups, the model was used to forecast 12 test data groups. The results were then compared with the prediction results of artificial experience from 24 technicians. The study shows that the mean absolute error of the dip angle and azimuth at bit are only 0.51° and 0.68°, respectively, as predicted by the prediction model, which uses the logsig activation function and has a double-hidden-layer with a point structure of 9×6. The prediction error also follows a normal distribution. Compared with technicians who have worked for more than five years, the accuracy of prediction results from the BP neural network model is reduced by 33.9% and meets the needs of drilling path control.

Drilling tools and measuring system

- [1] F. Wang et al., “Implementation of underground longhole directional drilling technology for greenhouse gas mitigation in Chinese coal mines,” Int. J. of Greenhouse Gas Control, Vol.11, pp. 290-303, 2012.

- [2] F. Hungerford and M. Fagan, “Over-core recovery of a drill string bogged in a longhole,” Proc. of the 2019 Coal Operators Conf., Mining Engineering, pp. 18-20, 2019.

- [3] D. Huijin, H. Shijun, and F. Jie, “The Detection Method of Fire Abnormal Based on Directional Drilling in Complex Conditions of Mine,” Environment, Energy and Earth Sciences (E3S) Web of Conf., Vol.38, Article No.01007, 2018.

- [4] C. Xu et al., “Practice and Challenge of In-Seam Directional Borehole over 2000 m in Coal Mines in China,” Institute of Physics (IOP) Conf. Series: Earth and Environmental Science, Vol.332, Issue 2, Article No.022016, 2019.

- [5] L. Jiang et al., “Torsional Pendulum Drag Reduction Technology for Directional Drilling of Ultra Deep Hole in Underground Coal Mine,” Safety in Coal Mines, Vol.51, No.11, pp. 113-116, 2020.

- [6] N. Yao et al., “Progress of drilling technologies and equipments for complicated geological conditions in underground coal mines in China,” Coal Geology & Exploration, Vol.48, No.2, pp. 1-7, 2020.

- [7] Z. Shi et al., “Present situation and prospect of directional drilling technology and equipment while drilling measurement in underground coal mine,” Coal Science and Technology, Vol.47, No.5, pp. 22-28, 2019.

- [8] Z. Shi et al., “40 years of development and prospect on underground coal mine tunnel drilling technology and equipment in China,” Coal Science and Technology, Vol.48, No.4, pp. 3-35 2020.

- [9] T. Sun et al., “Forecasting Method of Directional Borehole Trajectory in Coal Mine Underground,” Coal Mining Technology, Vol.24, Issue 1, pp. 22-25, 2019.

- [10] L. Perneder and E. Detournay, “Equilibrium inclinations of straight boreholes,” Society of Petroleum Engineers (SPE) J., Vol.18, No.3, pp. 395-405, 2013.

- [11] M. Bayliss and J. Matheus, “Directional drilling tool simulation and system design,” Society of Automotive Engineers (SAE) Int. J. of Materials and Manufacturing, Vol.1, No.1, pp. 675-689, 2009.

- [12] Y. Shi et al., “A new method for build-up rate prediction of bottom-hole assembly in well drilling,” J. of China University of Petroleum (Edition of Natural Science), Vol.41, Issue 1, pp. 85-89, 2017.

- [13] H. Wei et al., “Application of large diameter directional roof drilling in upper corner gas control,” Coal Engineering, Vol.49, Issue 6, pp. 64-67, 2017.

- [14] N. Yao, “Development trend of nearly horizontal directional drilling technology in coal mines of China,” Coal Geology & Exploration, Vol.36, Issue 4, pp. 78-80, 2008.

- [15] X. Lin et al., “Realization and application of the intelligent geosteering decision making while drilling,” Oil Drilling & Production Technology, Vol.42, Issue 1, pp. 1-5, 2020.

- [16] Z. Zhang et al., “Geosteering drilling technology for the complex formation of Well Xia 92-H,” Oil Drilling & Production Technology, Vol.36, Issue 4, pp. 6-9, 2014.

- [17] Z. Cai et al., “Bilinear compensation control for attitude of directional drilling tools,” Control and Decision, Vol.35, Issue 7, pp. 1758-1764, 2020.

- [18] Z. Song et al., “Removal rate model of deterministic shear thickening polishing material based on BP neural network,” Surface Technology, Vol.49, Issue 11, pp. 320-325+357, 2020.

- [19] T. Zhang et al., “Wave friction correction method for a robot based on BP neural network,” Chinese J. of Engineering, Vol.41, No.8, pp. 1085-1091, 2019.

- [20] W. Zhao et al., “Prediction of magnetic body top based on BP neural network,” Oil Geophysical Prospecting, Vol.55, No.5, pp. 1139-1147, 2020.

- [21] S. Fang et al., “Effect of Number of Training Samples on ANN Prediction Accuracy for Cutting Force,” J. of Southwest Jiaotong University, Vol.40, No.5, pp. 637-640, 2005.

- [22] H. Fattahi and H. Bazdar, “Applying improved artificial neural network models to evaluate drilling rate index,” Tunnelling and Underground Space Technology, Vol.70, pp. 114-124, 2017.

- [23] Z. Shi et al., “Key technology of drilling in-seam directional borehole of 3000 m in underground coal mine,” Coal Geology & Exploration, Vol.47, Issue 6, pp. 1-7, 2019.

- [24] Z. Shi et al., “Development path and key technology analysis of intelligent directional drilling in underground coal mine,” J. of China Coal Society, Vol.45, Issue 6, pp. 2217-2224, 2020.

- [25] X. Jin, “The key technology for drilling pressure-releasing gas drainage hole in roof strata,” Coal Geology & Exploration, Vol.44, Issue 3, pp. 124-127, 2016.

- [26] X. Liu et al., “Study on the geometric build angle rate of steerable motor,” Acta Petrolei Sinica, Vol.25, Issue 6, pp. 83-87, 2004.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.