Paper:

Design and Implementation of a Stiffness-Switching Joint for Versatile Assembly Systems

Maike He*,†, Tokuo Tsuji**

, Masanori Ueda*

, Masanori Ueda*

, Tatsuhiro Hiramitsu**

, Tatsuhiro Hiramitsu**

, and Hiroaki Seki**

, and Hiroaki Seki**

*Graduate School of Natural Science and Technology, Kanazawa University

Kakuma-machi, Kanazawa, Ishikawa 920-1192, Japan

†Corresponding author

**Institute of Science and Technology, Kanazawa University

Kakuma-machi, Kanazawa, Ishikawa 920-1192, Japan

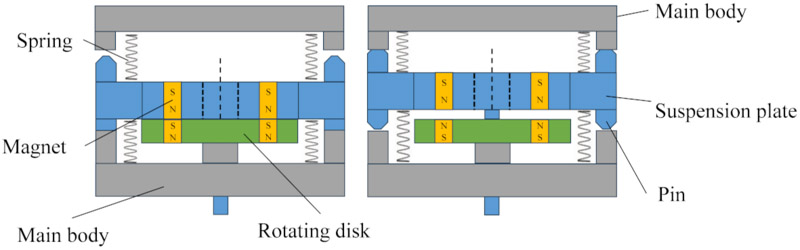

In this paper, we present a robotic joint with adjustable stiffness for versatile assembly systems. A typical rigid robotic arm equipped with this joint can perform multiple tasks, which contributes to the development of flexible systems. This joint consists of two main parts, the main body and suspension plate, with springs and magnets used to form the joint. The main body is directly mounted on the robot, while the suspension plate is connected to the robotic gripper. In this paper, we also discuss the requirements for selecting the springs and magnets, which serve as a reference for the fabrication of this joint. This joint features two modes (low and high stiffness) and is capable of switching between these modes by rotating a disk equipped with magnets. The switching between the low- and high-stiffness modes is very fast, with a transition time of less than 0.5 s. The joint in the low-stiffness mode has six degrees of freedom, indicating its high flexibility. The joint in the high-stiffness mode does not require additional force to maintain its stiffness. The results from the stiffness measurements show that the stiffness of the joint in the high-stiffness mode is approximately five times that of the joint in the low-stiffness mode. The theoretical stiffness of the joint is calculated and compared with values obtained from experiments, and the results are consistent with the experimental results. The effectiveness of the two stiffness modes is confirmed through peg-in-hole and coating experiments.

Stiffness switching by magnetic force

- [1] P. Hofmann, C. Samp, and N. Urbach, “Robotic process automation,” Electron. Mark., Vol.30, No.1, pp. 99-106, 2020. https://doi.org/10.1007/s12525-019-00365-8

- [2] E. Garcia, M. A. Jimenez, P. G. De Santos, and M. Armada, “The evolution of robotics research,” IEEE Robot. Autom. Mag., Vol.14, No.1, pp. 90-103, 2007. https://doi.org/10.1109/MRA.2007.339608

- [3] M. G. Mehrabi, A. G. Ulsoy, and Y. Koren, “Reconfigurable manufacturing systems: Key to future manufacturing,” J. Intell. Manuf., Vol.11, No.4, pp. 403-419, 2000. https://doi.org/10.1023/A:1008930403506

- [4] R. Sundar, A. N. Balaji, and R. M. S. Kumar, “A review on lean manufacturing implementation techniques,” Procedia Eng., Vol.97, pp. 1875-1885, 2014. https://doi.org/10.1016/j.proeng.2014.12.341

- [5] V. I. Cesaní and H. J. Steudel, “A study of labor assignment flexibility in cellular manufacturing systems,” Comput. Ind. Eng., Vol.48, No.3, pp. 571-591, 2005. https://doi.org/10.1016/j.cie.2003.04.001

- [6] Z. M. Bi and W. J. Zhang, “Flexible fixture design and automation: Review, issues, and future directions,” Int. J. Prod. Res., Vol.39, No.13, pp. 2867-2894, 2001. https://doi.org/10.1080/00207540110054579

- [7] L. Kong, X. Peng, Y. Chen, P. Wang, and M. Xu, “Multi-sensor measurement and data fusion technology for manufacturing process monitoring: A literature review,” Int. J. Extrem. Manuf., Vol.2, No.2, Article No.022001, 2020. https://doi.org/10.1088/2631-7990/ab7ae6

- [8] Y. Xia, Y. Yin, and Z. Chen, “Dynamic analysis for peg-in-hole assembly with contact deformation,” Int. J. Adv. Manuf. Technol., Vol.30, No.1, pp. 118-128, 2006. https://doi.org/10.1007/s00170-005-0047-4

- [9] P. J. Blau, “The significance and use of the friction coefficient,” Tribol. Int., Vol.34, No.9, pp. 585-591, 2001. https://doi.org/10.1016/S0301-679X(01)00050-0

- [10] D. E. Whitney, “Quasi-static assembly of compliantly supported rigid parts,” J. Dyn. Syst. Meas. Control, Vol.104, No.1, pp. 65-77, 1982. https://doi.org/10.1115/1.3149634

- [11] H. Park, J.-H. Bae, J.-H. Park, M.-H. Baeg, and J. Park, “Intuitive peg-in-hole assembly strategy with a compliant manipulator,” IEEE ISR 2013, 2013. https://doi.org/10.1109/ISR.2013.6695699

- [12] T. Tang, H.-C. Lin, Y. Zhao, W. Chen, and M. Tomizuka, “Autonomous alignment of peg and hole by force/torque measurement for robotic assembly,” 2016 IEEE Int. Conf. Autom. Sci. Eng. (CASE), pp. 162-167, 2016. https://doi.org/10.1109/COASE.2016.7743375

- [13] S. Huang, K. Murakami, Y. Yamakawa, T. Senoo, and M. Ishikawa, “Fast peg-and-hole alignment using visual compliance,” 2013 IEEE/RSJ Int. Conf. Intell. Robots Syst., pp. 286-292, 2013. https://doi.org/10.1109/IROS.2013.6696366

- [14] M. K. Lee, “Design of a high stiffness machining robot arm using double parallel mechanisms,” Proc. 1995 IEEE Int. Conf. Robot. Autom., Vol.1, pp. 234-240, 1995. https://doi.org/10.1109/ROBOT.1995.525291

- [15] J. Wang, H. Zhang, and T. Fuhlbrigge, “Improving machining accuracy with robot deformation compensation,” 2009 IEEE/RSJ Int. Conf. Intell. Robots Syst., pp. 3826-3831, 2009. https://doi.org/10.1109/IROS.2009.5353988

- [16] D. Shen, Q. Zhang, Y. Han, C. Tu, and X. Wang, “Design and development of a continuum robot with switching-stiffness,” Soft Robot., Vol.10, No.5, pp. 1015-1027, 2023. https://doi.org/10.1089/soro.2022.0179

- [17] A. M. Nasab, A. Sabzehzar, M. Tatari, C. Majidi, and W. Shan, “A soft gripper with rigidity tunable elastomer strips as ligaments,” Soft Robot., Vol.4, No.4, pp. 411-420, 2017. https://doi.org/10.1089/soro.2016.0039

- [18] H. Maike et al., “Flexible assembly system with stiffness switching joint,” Proc. 2023 Int. Conf. Artif. Life Robot, pp. 393-396, 2023. https://doi.org/10.5954/ICAROB.2023.OS16-3

- [19] J. Choi, S. Park, W. Lee, and S.-C. Kang, “Design of a robot joint with variable stiffness,” 2008 IEEE Int. Conf. Robot Autom., pp. 1760-1765, 2008. https://doi.org/10.1109/ROBOT.2008.4543455

- [20] S. Wolf and G. Hirzinger, “A new variable stiffness design: Matching requirements of the next robot generation,” 2008 IEEE Int. Conf. Robot Autom., pp. 1741-1746, 2008. https://doi.org/10.1109/ROBOT.2008.4543452

- [21] J. Choi, S. Hong, W. Lee, S. Kang, and M. Kim, “A robot joint with variable stiffness using leaf springs,” IEEE Trans. Robot., Vol.27, No.2, pp. 229-238, 2011. https://doi.org/10.1109/TRO.2010.2100450

- [22] L. Wang et al., “Controllable and reversible tuning of material rigidity for robot applications,” Mater. Today, Vol.21, No.5, pp. 563-576, 2018. https://doi.org/10.1016/j.mattod.2017.10.010

- [23] M. Tennomi et al., “Development of assembly system for quick and low-cost installation,” Adv. Robot., Vol.34, Nos.7-8, pp. 531-545, 2020. https://doi.org/10.1080/01691864.2020.1738271

- [24] S. van der Walt et al., “scikit-image: Image processing in Python,” PeerJ, Vol.2, Article No.e453, 2014. https://doi.org/10.7717/peerj.453

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.