Research Paper:

Integral Sliding Mode Impedance Control Incorporating Exponential Reaching Law for Grinding Robot

Lin Jia*

, Huan Chen*, Changfan Zhang*

, Huan Chen*, Changfan Zhang*

, Zhongmei Wang*,†, and Li Liu**

, Zhongmei Wang*,†, and Li Liu**

*College of Railway Transportation, Hunan University of Technology

Taishan West Road, Tianyuan District, Zhuzhou, Hunan 412007, China

†Corresponding author

**College of Engineering and Design, Hunan Normal University

Taozihu Road, Yuelu District, Changsha, Hunan 410081, China

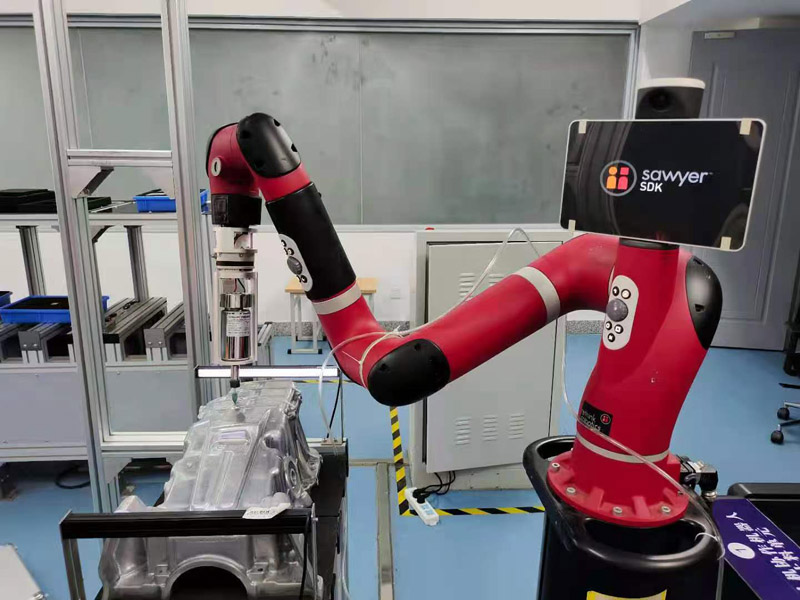

To address the issue of traditional control methods being inadequate for achieving high-precision grinding of complex surfaces, this study proposes an improved impedance control method designed for grinding robots. The proposed method operates within the Cartesian coordinate system and incorporates an exponential reaching law to enhance the machining quality of freeform surface workpieces. The method begins by calculating the executable impedance trajectory of the robot based on the impedance parameter model of the system and the obtained contact resistance. This trajectory serves as a reference for precise motion. Subsequently, a control method based on integral sliding mode impedance has been proposed to enable precise tracking of the calculated impedance trajectory. To resolve the widely recognized issue of chattering in sliding mode control, the exponential reaching law has been employed to effectively suppress the chattering effect, thereby enhancing the smoothness and stability of the control process. Additionally, the stability of the system has been thoroughly analyzed and validated using Lyapunov theory, guaranteeing its theoretical soundness and dependability. Finally, comprehensive simulations and experiments have been performed to evaluate the proposed approach under various operational conditions. The results thus obtained confirm that the method achieves a superior performance under dynamic as well as static conditions, offering improved precision and stability for grinding tasks on complex surfaces.

ERL-ISMIC for grinding robot

- [1] L. Gracia et al., “Adaptive sliding mode control for robotic surface treatment using force feedback,” Mechatronics, Vol.52, pp. 102-118, 2018. https://doi.org/10.1016/j.mechatronics.2018.04.008

- [2] Y. Huo et al., “Model-free adaptive impedance control for autonomous robotic sanding,” IEEE Trans. on Automation Science and Engineering, Vol.19, No.4, pp. 3601-3611, 2021. https://doi.org/10.1109/tase.2021.3126743

- [3] F. T. Han et al., “Nonlinear impedance control with trajectory adaptation for collaborative robotic grinding,” Science China Technological Sciences, Vol.66, No.7, pp. 1928-1936, 2023. https://doi.org/10.1007/s11431-022-2418-4

- [4] G. Wang et al., “PD-adaptive variable impedance constant force control of macro-mini robot for compliant grinding and polishing,” The Int. J. of Advanced Manufacturing Technology, Vol.124, No.7, pp. 2149-2170, 2023. https://doi.org/10.1007/s00170-022-10405-x

- [5] T. Wang et al., “Sliding mode impedance control for dual hand master single slave teleoperation systems,” IEEE Trans. on Intelligent Transportation Systems, Vol.23, No.12, pp. 25500-25508, 2021. https://doi.org/10.1109/tits.2021.3094553

- [6] P. Dai et al., “Sliding mode impedance control for contact intervention of an I-AUV: Simulation and experimental validation,” Ocean Engineering, Vol.196, Article No.106855, 2020. https://doi.org/10.1016/j.oceaneng.2019.106855

- [7] Y. Rong et al., “Robust fault-tolerant motion/force control of a fully-actuated hexarotor using adaptive sliding mode impedance control,” Int. J. of Robust and Nonlinear Control, Vol.32, No.7, pp. 4149-4172, 2022. https://doi.org/10.1002/rnc.6005

- [8] G. Zheng et al., “Fuzzy adaptive sliding mode impedance control of fracture reduction robot,” IEEE Access, Vol.9, pp. 113653-113665, 2021. https://doi.org/10.1109/access.2021.3099692

- [9] M. M. Rayguru et al., “A time delay estimation based adaptive sliding mode strategy for hybrid impedance control,” IEEE Access, Vol.8, pp. 155352-155361, 2020. https://doi.org/10.1109/access.2020.3019429

- [10] K. Adamiak et al., “Novel power-rate reaching law for quasi-sliding mode control,” Energies, Vol.15, No.15, Article No.5446, 2022. https://doi.org/10.3390/en15155446

- [11] F. Haroon et al., “Second-order rotating sliding mode control with composite reaching law for two level single phase voltage source inverters,” IEEE Access, Vol.10, pp. 60177-60188, 2022. https://doi.org/10.1109/access.2022.3180501

- [12] J. He et al., “Robust predictive current control of permanent magnet synchronous motor using voltage coefficient matrix update,” Int. J. of Electrical Power & Energy Systems, Vol.159, Article No.109999, 2024. https://doi.org/10.1016/j.ijepes.2024.109999

- [13] P. Prasun et al., “Difference equation with minima-based discrete-time sliding mode control,” IEEE Trans. on Circuits and Systems II: Express Briefs, Vol.70, No.12, pp. 4404-4408, 2023. https://doi.org/10.1109/tcsii.2023.3287390

- [14] Y. Qu et al., “Sliding-mode anti-disturbance speed control of permanent magnet synchronous motor based on an advanced reaching law,” ISA Trans., Vol.139, pp. 436-447, 2023. https://doi.org/10.1016/j.isatra.2023.04.016

- [15] L. Feng et al., “Advanced torque sharing function strategy with sliding mode control for switched reluctance motors,” IEEE Trans. on Transportation Electrification, Vol.10, No.1, pp. 2302-2311, 2023. https://doi.org/10.1109/tte.2023.3287159

- [16] E. Spyrakos-Papastavridis et al., “Passivity preservation for variable impedance control of compliant robots,” IEEE/ASME Trans. on Mechatronics, Vol.25, No.5, pp. 2342-2353, 2019. https://doi.org/10.1109/tmech.2019.2961478

- [17] G. Peng et al., “Robust admittance control of optimized robot–environment interaction using reference adaptation,” IEEE Trans. on Neural Networks and Learning Systems, Vol.34, No.9, pp. 5804-5815, 2022. https://doi.org/10.1109/tnnls.2021.3131261

- [18] K. Zhou et al., “Admittance control design and system testing of industrial robot polishing operation,” Proc. of the Institution of Mechanical Engineers, Part B: J. of Engineering Manufacture, Vol.237, No.10, pp. 1538-1552, 2023. https://doi.org/10.1177/09544054221136513

- [19] G. He et al., “Variable impedance control of cable actuated continuum manipulators,” Int. J. of Control, Automation and Systems, Vol.18, No.7, pp. 1839-1852, 2020. https://doi.org/10.1007/s12555-019-0449-y

- [20] A. Stolfi et al., “A combined impedance-PD approach for controlling a dual-arm space manipulator in the capture of a non-cooperative target,” Acta Astronautica, Vol.139, pp. 243-253, 2017. https://doi.org/10.1016/j.actaastro.2017.07.014

- [21] Y. Li et al., “Servo motor sliding mode control based on fuzzy power index method,” Computers & Electrical Engineering, Vol.94, Article No.107351, 2021. https://doi.org/10.1016/j.compeleceng.2021.107351

- [22] X. Miao et al., “Novel composite speed control of permanent magnet synchronous motor using integral sliding mode approach,” Mathematics, Vol.11, No.22, Article No.4666, 2023. https://doi.org/10.3390/math11224666

- [23] A. G. Iyer et al., “Sliding mode control using power rate exponential reaching law for urban platooning,” IFAC-PapersOnLine, Vol.55, No.1, pp. 516-521, 2022. https://doi.org/10.1016/j.ifacol.2022.04.085

- [24] J. Zhai and G. Xu, “A novel non-singular terminal sliding mode trajectory tracking control for robotic manipulators,” IEEE Trans. on Circuits and Systems II: Express Briefs, Vol.68, No.1, pp. 391-395, 2020. https://doi.org/10.1109/tcsii.2020.2999937

- [25] S. Cui et al., “Trajectory tracking control of mobile manipulator based on improved sliding mode control algorithm,” Processes, Vol.12, No.5, Article No.881, 2024. https://doi.org/10.3390/pr12050881

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.