Research Paper:

Switching Prediction of Sliding and Rotating Modes in Compound Directional Drilling Based on Sliding Window

Lijuan Fan*1,*2,*3, Chengda Lu*2,*3,*4,†

, Hao Li*5,*6, Wangnian Li*2,*3,*4,*5, Hongchao Wei*5, and Min Wu*1,*2,*3,*4

, Hao Li*5,*6, Wangnian Li*2,*3,*4,*5, Hongchao Wei*5, and Min Wu*1,*2,*3,*4

*1School of Future Technology, China University of Geosciences

No.388 Lumo Road, Hongshan District, Wuhan, Hubei 430074, China

*2Hubei Key Laboratory of Advanced Control and Intelligent Automation for Complex Systems

No.388 Lumo Road, Hongshan District, Wuhan, Hubei 430074, China

*3Engineering Research Center of Intelligent Technology for Geo-Exploration, Ministry of Education

No.388 Lumo Road, Hongshan District, Wuhan, Hubei 430074, China

*4School of Automation, China University of Geosciences

No.388 Lumo Road, Hongshan District, Wuhan, Hubei 430074, China

*5CCTEG Xi’an Research Institute (Group) Co., Ltd.

No.82 Jinye 1st Road, High-tech Industrial Development Zone, Xi’an, Shaanxi 710077, China

*6China Coal Research Institute

Beijing , China

†Corresponding author

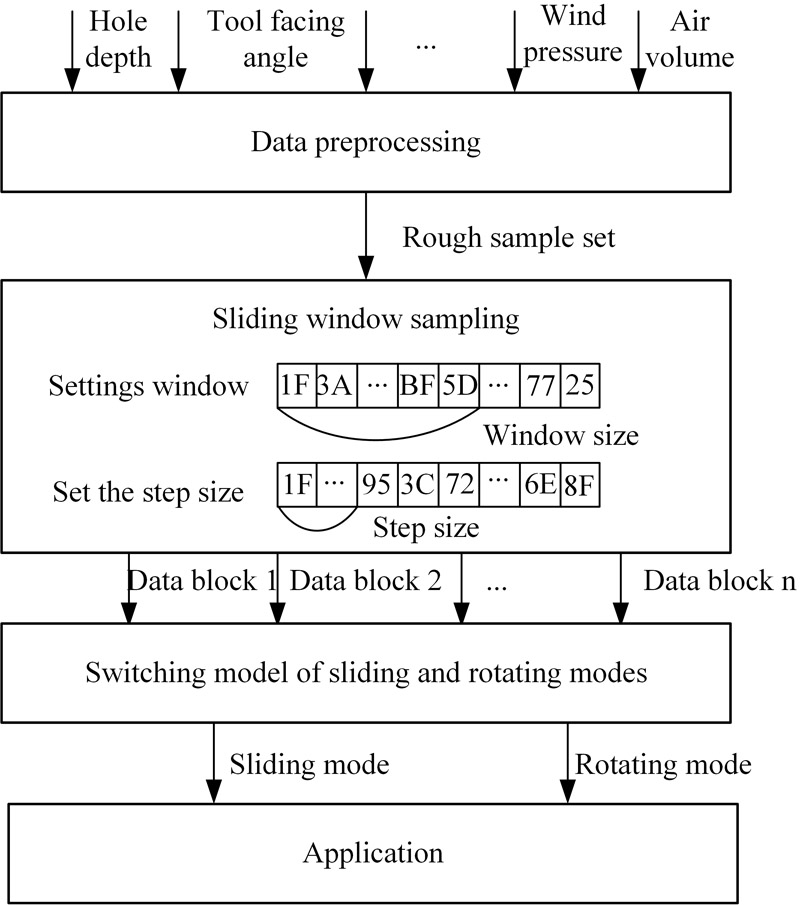

Compound directional drilling consists of sliding and rotating modes. The two modes alternate to achieve trajectory extension, where the sliding mode achieves trajectory deviation and the rotating mode maintains the trajectory. When to switch between the two modes plays an important role in obtaining a satisfactory drilling trajectory. In this study, the switching of the two modes is considered as a prediction problem and is achieved by using the random forest algorithm. First, the collected raw data were preprocessed, where the linear interpolation was used to fill the missing values and the feature importance assessment was applied to select seven decision variables. Secondly, the pre-processed dataset consisting of the seven decision variables was divided into multiple data blocks through the sliding window mechanism. Lastly, the random forest algorithm was adopted to predict the results for the data blocks. A case study shows that our method provides an effective solution to predicting when to switch the two modes in compound directional drilling.

Switching prediction flowchart

- [1] C. Ke and X. Song, “Control design for directional down-hole drilling using dual-heuristic programming with a high-order dynamic switching model,” IEEE Trans. on Control Systems Technology, Vol.30, No.3, pp. 1009-1020, 2022. https://doi.org/10.1109/TCST.2021.3094537

- [2] Y. Yang, Y. Yang, H. Ren, Q. Qi, and X. Chen, “Research on the working mechanism of the PDC drill bit in compound drilling,” J. of Petroleum Science and Engineering, Vol.185, Article No.106647, 2020. https://doi.org/10.1016/j.petrol.2019.106647

- [3] Z. Shi et al., “40 years of development and prospect on underground coal mine tunnel drilling technology and equipment in China,” Coal Science and Technology, Vol.48, No.4, pp. 1-34, 2020. https://doi.org/10.13199/j.cnki.cst.2020.04.001

- [4] W. Li et al., “Design of an intelligent control system for compound directional drilling in underground coal mines,” J. Adv. Comput. Intell. Intell. Inform., Vol.28, No.4, pp. 1052-1062, 2024. https://doi.org/10.20965/jaciii.2024.p1052

- [5] B. T. H. Marbun, R. H. Ridwan, H. S. Nugraha, S. Z. Sinaga, and B. A. Purbantanu, “Review of directional drilling design and operation of geothermal wells in Indonesia,” Renewable Energy, Vol.176, pp. 135-152, 2021. https://doi.org/10.1016/j.renene.2021.05.078

- [6] H. Wang, E. Wang, Z. Li, R. Shen, and X. Liu, “Study and application of a new gas pressure inversion model in coal seam while drilling based on directional drilling technology,” Fuel, Vol.306, Article No.121679, 2021. https://doi.org/10.1016/j.fuel.2021.121679

- [7] X. Wang, H. Ni, R. Shor, and R. Wang, “A model-based optimization and control method of slide drilling operations,” J. of Petroleum Science and Engineering, Vol.198, Article No.108203, 2021. https://doi.org/10.1016/j.petrol.2020.108203

- [8] J. Zhao, J. Zhao, C. Xu, and Z. Wu, “Composite directional drilling technology in underground coal mine,” Coal Geology & Exploration, Vol.46, No.4, pp. 202-206, 2018 (in Chinese). https://doi.org/10.3969/j.issn.1001-1986.2018.04.033

- [9] X.-Y. Zhong et al., “A time-optimal wellbore trajectory design for slide drilling systems,” Structural and Multidisciplinary Optimization, Vol.63, No.2, pp. 881-896, 2021. https://doi.org/10.1007/s00158-020-02732-y

- [10] Y. Gao, F. Li, and J. Chen, “Random weighting adaptive estimation of model errors on attitude measurement for rotary steerable system,” IEEE Access, Vol.10, pp. 80794-80803, 2022. https://doi.org/10.1109/ACCESS.2022.3195519

- [11] B. Ozdemir, E. Kilickap, E. Bahce, A. Yardimeden, and E. Emir, “Optimization of parameters for drilling composite materials with freeform surfaces,” Materials and Manufacturing Processes, Vol.39, No.1, pp. 55-68, 2024. https://doi.org/10.1080/10426914.2023.2187826

- [12] H. Chu et al., “Enhancing the benefit of slide steering drilling systems in horizontal wells of unconventional reservoirs,” Frontiers in Energy Research, Vol.11, Article No.1267228, 2023. https://doi.org/10.3389/fenrg.2023.1267228

- [13] Y. Zhang, W. Cheng, S. Hu, T. Guo, and Z. Meng, “Piecewise in-plane calibration for drilling inclinometer system,” IEEE Sensors J., Vol.24, No.20, pp. 31816-31826, 2024. https://doi.org/10.1109/JSEN.2024.3440916

- [14] Y. Zhou et al., “A novel rate of penetration model based on support vector regression and modified bat algorithm,” IEEE Trans. on Industrial Informatics, Vol.19, No.5, pp. 6659-6668, 2023. https://doi.org/10.1109/TII.2022.3205374

- [15] D. Zhang et al., “Tube-based adaptive model predictive control for deviation correction in vertical drilling process,” IEEE Trans. on Industrial Electronics, Vol.69, No.9, pp. 9419-9428, 2022. https://doi.org/10.1109/TIE.2021.3113020

- [16] W. Li et al., “Modeling and optimization of trajectory deviation for compound directional drilling in coal mines,” Neurocomputing, Vol.618, Article No.129029, 2025. https://doi.org/10.1016/j.neucom.2024.129029

- [17] S. Dey, F. Z. Taousser, M. Djemai, M. Defoort, and S. Di Gennaro, “Observer based leader–follower bipartite consensus with intermittent failures using Lyapunov functions and time scale theory,” IEEE Control Systems Letters, Vol.5, No.6, pp. 1904-1909, 2021. https://doi.org/10.1109/LCSYS.2020.3040944

- [18] S. Cheng, B. Xin, J. Chen, and F. Deng, “Predefined-time distributed fault-tolerant control for nonlinear multiagent systems suffering from nonaffine faults,” IEEE Trans. on Systems, Man, and Cybernetics: Systems, Vol.55, No.5, pp. 3300-3311, 2025. https://doi.org/10.1109/TSMC.2025.3540464

- [19] Z. Wang, N. Liu, and Y. Guo, “Adaptive sliding window LSTM NN based RUL prediction for lithium-ion batteries integrating LTSA feature reconstruction,” Neurocomputing, Vol.466, pp. 178-189, 2021. https://doi.org/10.1016/j.neucom.2021.09.025

- [20] Y. Qin, Y. Yan, H. Ji, and Y. Wang, “Recursive correlative statistical analysis method with sliding windows for incipient fault detection,” IEEE Trans. on Industrial Electronics, Vol.69, No.4, pp. 4185-4194, 2022. https://doi.org/10.1109/TIE.2021.3070521

- [21] H. Fan et al., “Distributed monitoring with integrated probability PCA and mRMR for drilling processes,” IEEE Trans. on Instrumentation and Measurement, Vol.71, Article No.3516213, 2022. https://doi.org/10.1109/TIM.2022.3186081

- [22] T. I. Larsen, A. A. Pilehvari, and J. J. Azar, “Development of a new cuttings-transport model for high-angle wellbores including horizontal wells,” SPE Drilling & Completion, Vol.12, No.2, pp. 129-135, 1997. https://doi.org/10.2118/25872-PA

- [23] T. Zhang et al., “A novel feature evaluation method in mapping forest AGB by fusing multiple evaluation metrics using PolSAR data,” IEEE Geoscience and Remote Sensing Letters, Vol.21, Article No.4006605, 2024. https://doi.org/10.1109/LGRS.2024.3378425

- [24] E. Saccenti, M. H. W. B. Hendriks, and A. K. Smilde, “Corruption of the Pearson correlation coefficient by measurement error and its estimation, bias, and correction under different error models,” Scientific Reports, Vol.10, Article No.438, 2022. https://doi.org/10.1038/s41598-019-57247-4

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.