Paper:

Contact Force Control and Experimental Verification of a Mobile Robot for Picking Up Objects on the Ground

Ryuji Sato*,** and Naoki Uchiyama*

*Department of Mechanical Engineering, Toyohashi University of Technology

1-1 Hibarigaoka, Tempaku, Toyohashi, Aichi 441-8580, Japan

**Department of Research and Development, Konica Minolta, Inc.

3-22-1 Honohara, Toyokawa, Aichi 442-8503, Japan

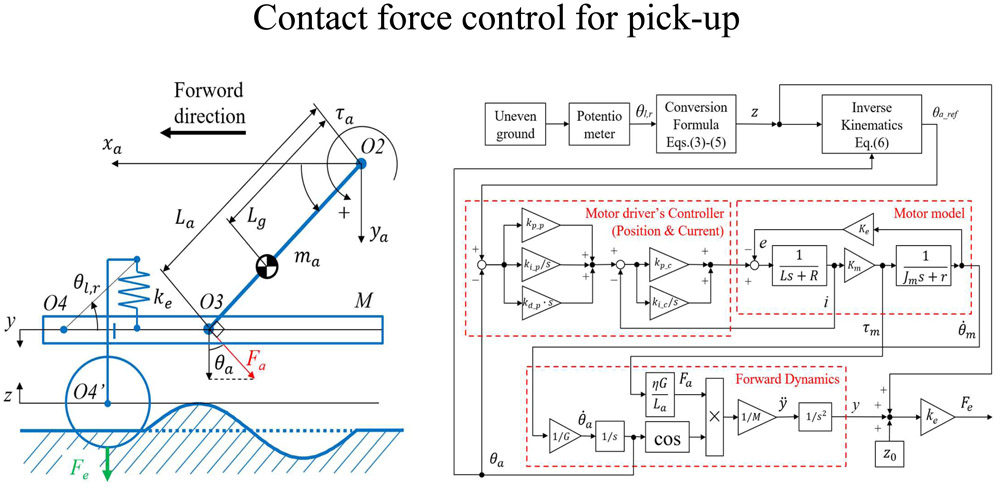

This study presents a robot that efficiently picks up objects scattered on the ground, such as nuts in outdoor work. In conventional methods, objects are generally picked up by a gripper attached to the end of an arm; however, picking them up one by one is time-consuming. In addition, difficulties arise from the complexity required for coordinated control of the grasping posture and movement to pick up the object, as well as from the high rigidity of the machine when working on uneven ground. In this study, a cage-type end-effector is employed to enable continuous pick-up while the robot moves. In addition, using a worm gear for the arm, an arm-type mobile robot with a small size, simple drive source, and high mechanical safety is designed. To improve the pick-up capability, force control that allows the end-effector to flexibly follow the unevenness of the ground is desirable. However, force control is generally considered difficult because a worm gear cannot be driven in reverse. Therefore, we constructed a contact force control system that adjusts the arm angle by measuring the unevenness of the ground as spring displacement around the end-effector. This control system prevents excessive contact force between the end-effector and the ground. Experiments in an outdoor environment confirmed that the variation in the number of nuts picked up was reduced by approximately 48% compared to the case without the control. These results demonstrate the effectiveness of the pick-up system proposed in this study.

Contact force control for pick-up

- [1] N. Murakami, “Status and future in robotic harvester,” J. of the Robotics Society of Japan, Vol.39, No.10, pp. 885-887, 2021 (in Japanese). https://doi.org/10.7210/jrsj.39.885

- [2] T. Hasegawa, “Development of ‘FARO,’ an automatic tomato harvesting robot,” J. of the Robotics Society of Japan, Vol.39, No.10, pp. 907-910, 2021 (in Japanese). https://doi.org/10.7210/jrsj.39.907

- [3] K. Ozaki, S. Hara, Y. Shikanai, T. Ooyama, and S. Idei, “Development of a strawberry picking robot: Picking for high quality strawberries without a touch of their skins,” Proc. of the 2010 JSME Annual Conf. on Robotics and Mechatronics, Article No.1A1-A21, 2010 (in Japanese). https://doi.org/10.1299/jsmermd.2010._1A1-A21_1

- [4] N. Taguchi et al., “Development of a fully automatic harvesting robot system,” Report of Industrial Technology Center of Nagasaki, No.39, pp. 3-8, 2010 (in Japanese).

- [5] J. Saito, “Suspended automatic harvesting robot utilizing AI,” J. of the Robotics Society of Japan, Vol.39, No.10, pp. 901-906, 2021 (in Japanese). https://doi.org/10.7210/jrsj.39.901

- [6] S. Sugaya et al., “Automatic onion harvesting by height control of harvesting part with a depth camera,” Proc. of the 2020 JSME Annual Conf. on Robotics and Mechatronics, Article No.1A1-A204, 2020 (in Japanese). https://doi.org/10.1299/jsmermd.2020.1A1-A04

- [7] M. Asano, K. Onishi, and T. Fukao, “Robust cabbage recognition and automatic harvesting against environmental changes,” Proc. of the 2021 JSME Annual Conf. on Robotics and Mechatronics, Article No.1P2-A06, 2021 (in Japanese).

- [8] Legmin Inc., “Agricultural traveling vehicle, control device and program,” JP Patent, 6700500, 2020.

- [9] Saya Giken, Inc., “Sphere accenting device,” JP Patent, 08-000769, 1996.

- [10] T. R. Schafle, A. Tokui, and N. Uchiyama, “A hybrid systems approach with input-output linearization for automotive parking control of a nonholonomic mobile robot,” 3rd Int. Conf. on Advanced Robotics and Mechatronics, 2018. https://doi.org/10.1109/ICARM.2018.8610844

- [11] T. R. Schäfle, M. Mitschke, and N. Uchiyama, “Generation of optimal coverage paths for mobile robots using hybrid genetic algorithm,” J. Robot. Mechatron., Vol.33, No.1, pp. 11-23, 2021. https://doi.org/10.20965/jrm.2021.p0011

- [12] T. R. Schäfle and N. Uchiyama, “Probabilistic robust path planning for nonholonomic arbitrary-shaped mobile robots using a hybrid A* algorithm,” IEEE Access, Vol.9, pp. 93466-93479, 2021. https://doi.org/10.1109/ACCESS.2021.3093471

- [13] T. R. Schäfle, S. Mohamed, N. Uchiyama, and O. Sawodny, “Coverage path planning for mobile robots using genetic algorithm with energy optimization,” 2016 Int. Electronics Symp., pp. 99-104, 2016. https://doi.org/10.1109/ELECSYM.2016.7860983

- [14] M. Mitschke, N. Uchiyama, and O. Sawodny, “Online coverage path planning for a mobile robot considering energy consumption,” IEEE 14th Int. Conf. on Automation Science and Engineering, pp. 1473-1478, 2018. https://doi.org/10.1109/COASE.2018.8560376

- [15] National Institute of Technology, Prefectural University of Kumamoto, and Suematsu Denshi Co., Ltd., “Chestnut harvester,” JP Patent, 7296072, 2023.

- [16] R. Sato, K. Kakihara, Y. Sagoh, R. Kakihara, and N. Uchiyama, “Design and experimental verification of a mobile robot for picking up objects on the ground,” J. of the Robotics Society of Japan. Vol.41, No.1, pp. 82-91, 2023 (in Japanese). https://doi.org/10.7210/jrsj.41.82

- [17] T. Kubayashi et al., “Numbers of fruits and conditions of seeds in fruits of Camellia japonica planted on a farm land in Goto Islands,” Bulletin of the Nagasaki Agricultural & Forestry Technical Development Center, Vol.1, pp. 135-144, 2010.

- [18] H. Osumi, “Control strategy for mobile manipulators,” J. of the Robotics Society of Japan, Vol.13, No.7, pp. 904-907, 1995 (in Japanese). https://doi.org/10.7210/jrsj.13.904

- [19] W. Shan, K. Nagatani, and Y. Tanaka, “Motion planning for mobile manipulator to pickup objects with base’s moving,” Proc. of the Robotics Society of Japan 20th Anniversary Conf., Article No.3B33, 2002 (in Japanese).

- [20] H. Date, S. Ohkawa, Y. Takita, and J. Kikuchi, “High precision localization of mobile robot using LIDAR intensity of surface,” Trans. of the Japan Society of Mechanical Engineers, Ser. C, Vol.79, No.806, pp. 3389-3398, 2013 (in Japanese). https://doi.org/10.1299/kikaic.79.3389

- [21] K. Tanie and T. Fukuda, “Compliance control of a robotic arm and its application to soft contact tasks,” J. of the Japan Society for Precision Engineering, Vol.55, No.7, pp. 1189-1193, 1989 (in Japanese). https://doi.org/10.2493/jjspe.55.1189

- [22] T. Yamada, A. Tanaka, M. Yamada, Y. Funahashi, and H. Yamamoto, “Identification of contact conditions by active force sensing – Estimated Parameter Uncertainty and Experimental Verification –,” J. Robot. Mechatron., Vol.23, No.1, pp. 44-52, 2011. https://doi.org/10.20965/jrm.2011.p0044

- [23] I. Hashlamon and K. Erbatur, “Ground reaction force sensor fault detection and recovery method based on virtual force sensor for walking biped robots,” 9th Asian Control Conf., 2013. https://doi.org/10.1109/ASCC.2013.6606340

- [24] Z. Cong et al., “Contact force estimation method of legged-robot and its application in impedance control,” IEEE Access, Vol.8, pp. 161175-161187, 2020. https://doi.org/10.1109/ACCESS.2020.3021080

- [25] T. Iwamoto, Y. Itai, K. Shiroyama, and A. Nagano, “Realization of pseudo mechanism function using a worm gear,” J. of the Robotics Society of Japan, Vol.27, No.10, pp. 1154-1159, 2009 (in Japanese). https://doi.org/10.7210/jrsj.27.1154

- [26] K. Oda, Y. Ida, J. Ishikawa, M. Hiraoka, and S.-H. Hyon, “Realization of whole-body torque-controlled hydraulic wheel-on-leg rover,” J. of the Robotics Society of Japan, Vol.40, No.5, pp. 421-430, 2022 (in Japanese). https://doi.org/10.7210/jrsj.40.421

- [27] R. Sato, T. Chansocheat, and N. Uchiyama, “Visual servoing of a differential robot with image feature size and experimental verification,” 2022 IEEE/SICE Int. Symp. on System Integration, pp. 690-694, 2022. https://doi.org/10.1109/SII52469.2022.9708821

- [28] T. Ishiyama, M. Mizuno, C. Sinaga, R. Sato, and N. Uchiyama, “Mobile robot control for collecting objects scattered on the ground,” Proc of the 2023 Domestic Conf. of the System Integration Division, SICE (SI2023), Article No.3P2-A03, 2022 (in Japanese).

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.