Paper:

Multi-Legged Inspection Robot with Twist-Based Crouching and Fine Adjustment Mechanism

Maroay Phlernjai* and Photchara Ratsamee**

*Sirindhorn International Institute of Technology, Thammasat University

99 Moo 18, Km. 41 on Paholyothin Highway Khlong Luang, Pathum Thani 12120, Thailand

**Cyber Media Center, Osaka University

5-1 Mihogaoka, Ibaraki, Osaka 567-0047, Japan

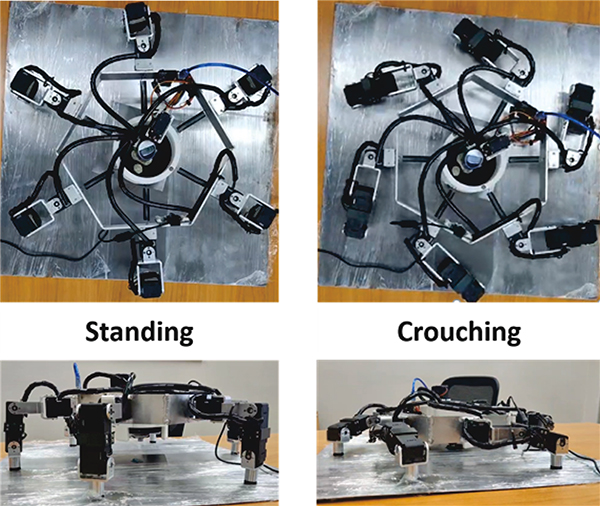

The monitoring and inspection of buildings, towers, and large chemical tanks can be dangerous and costly. A wall climbing multi-legged robot can climb and crouch to move the inspection probe closer to the wall surface. The typical wall-sticking crouching motion of multi-legged robot is unable to achieve this without an additional actuator at the foot base. This limits the design of a magnetic leg that is bulky enough to keep the robot stable during inspections. This paper provides the concept and implementation details of a coarse-to-fine inspection using a novel twisting motion to crouch the robot towards the steel surface without the need for an additional actuator at the magnetized foot joint. The center position error of this method is reported as less than 1 cm in radius. Additionally, this paper suggests using a linear motor to provide fine-tuning capability for the gentle touch of the ultrasonic inspection probe to the steel surface, protecting the probe from a direct crash during the coarse twisting crouch movement. Experiments have been conducted to confirm the validity of this concept on horizontally flat steel plates. The robot successfully crouch towards the surface and gently touch it with the ultrasonic probe. The results were reliable and comparable to manual inspection. For the 2 mm and 3 mm sample plates, the average measurement error compared to the ground truth from a vernier caliper was less than 2%, which is better than the measurement error (3%) of humans. The total time used was 2.475 seconds per inspection spot, which is 5.6 times faster compared to the expected time used to cover the same distance with a typical probe extension using a lead screw drive.

Twist-based crouching motion by multi-legged inspection robot for UT inspection

- [1] Y. Fujino, “Steel bridges in japan,” Steel Construction Today and Tomorrow, Vol.15, No.2, pp. 1-19, 2006.

- [2] S. Fujiwara, R. Kanehara, T. Okada, and T. Sanemori, “An articulated multi-vehicle robot for inspection and testing of pipeline interiors,” Proc. of 1993 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS’93), Vol.1, pp. 509-516, 1993.

- [3] H.-M. Thomas, T. Heckel, and G. Hanspach, “Advantage of a combined ultrasonic and eddy current examination for railway inspection trains,” Insight-Non-Destructive Testing and Condition Monitoring, Vol.49, No.6, pp. 341-344, 2007.

- [4] D. Mellinger, Q. Lindsey, M. Shomin, and V. Kumar, “Design, modeling, estimation and control for aerial grasping and manipulation,” 2011 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 2668-2673, 2011.

- [5] A. Briod, P. Kornatowski, J.-C. Zufferey, and D. Floreano, “A collision-resilient flying robot,” J. of Field Robotics, Vol.31, No.4, pp. 496-509, 2014.

- [6] D. Mellinger, N. Michael, and V. Kumar, “Trajectory generation and control for precise aggressive maneuvers with quadrotors,” The Int. J. of Robotics Research, 0278364911434236, 2012.

- [7] T. Ikeda, S. Yasui, S. Minamiyama, K. Ohara, S. Ashizawa, A. Ichikawa, A. Okino, T. Oomichi, and T. Fukuda, “Stable impact and contact force control by uav for inspection of floor slab of bridge,” Advanced Robotics, Vol.32, No.19, pp. 1061-1076, 2018.

- [8] M. Ryll, H. H. Bulthoff, and P. R. Giordano, “A Novel Overactuated Quadrotor Unmanned Aerial Vehicle: Modeling, Control, and Experimental Validation,” IEEE Trans. on Control Systems Technology, Vol.23, No.2, pp. 540-556, 2015.

- [9] S. Rajappa, M. Ryll, H. H. Bülthoff, and A. Franchi, “Modeling, control and design optimization for a fully-actuated hexarotor aerial vehicle with tilted propellers,” 2015 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 4006-4013, 2015.

- [10] P. Ratsamee, P. Kriengkomol, T. Arai, K. Kamiyama, Y. Mae, K. Kiyokawa, T. Mashita, Y. Uranishi, and H. Takemura, “A hybrid flying and walking robot for steel bridge inspection,” 2016 IEEE Int. Symposium on Safety, Security, and Rescue Robotics (SSRR), pp. 62-67, 2016.

- [11] W. Shen, J. Gu, and Y. Shen, “Proposed wall climbing robot with permanent magnetic tracks for inspecting oil tanks,” IEEE Int. Conf. Mechatronics and Automation, 2005, Vol.4. pp. 2072-2077, 2005.

- [12] Y. Zhang, T. Dodd, K. Atallah, and I. Lyne, “Design and optimization of magnetic wheel for wall and ceiling climbing robot,” 2010 Int. Conf. on Mechatronics and Automation (ICMA), pp. 1393-1398, 2010.

- [13] F. Tache, W. Fischer, G. Caprari, R. Siegwart, R. Moser, and F. Mondada, “Magnebike: A magnetic wheeled robot with high mobility for inspecting complex-shaped structures,” J. of Field Robotics, Vol.26, No.5, pp. 453-476, 2009.

- [14] S. T. Nguyen, A. Q. Pham, C. Motley, H. M. La et al., “A practical climbing robot for steel bridge inspection,” Proc. of the 2020 IEEE Int. Conf. on Robotics and Automation (ICRA), Paris, France, Vol.31, 2020.

- [15] A. Q. Pham, H. M. La, K. T. La, and M. T. Nguyen, “A magnetic wheeled robot for steel bridge inspection,” Int. Conf. on Engineering Research and Applications, Springer, pp. 11-17, 2019.

- [16] S. T. Nguyen and H. M. La, “Roller chain-like robot for steel bridge inspection,” Proc. of the 9th Int. Conf. on Structural Health Monitoring of Intelligent Infrastructure, 2019.

- [17] A. Mazumdar and H. H. Asada, “Mag-foot: A steel bridge inspection robot,” 2009 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 1691-1696, 2009.

- [18] P. Kriengkomol, K. Kamiyama, M. Kojima, M. Horade, Y. Mae, and T. Arai, “A new close-loop control method for an inspection robot equipped with electropermanent-magnets,” J. Robot. Mechatron., Vol.28, No.2, pp. 185-193, 2016.

- [19] O. Unver and M. Sitti, “A miniature ceiling walking robot with flat tacky elastomeric footpads,” IEEE Int. Conf. on Robotics and Automation 2009 (ICRA’09), pp. 2276-2281, 2009.

- [20] W. A. Breckwoldt, K. A. Daltorio, L. Heepe, A. D. Horchler, S. N. Gorb, and R. D. Quinn, “Walking inverted on ceilings with wheel-legs and micro-structured adhesives,” 2015 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 3308-3313, 2015.

- [21] E. W. Hawkes, D. L. Christensen, and M. R. Cutkosky, “Vertical dry adhesive climbing with a 100× bodyweight payload,” 2015 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 3762-3769, 2015.

- [22] A. Saito, K. Nagayama, K. Ito, T. Oomichi, S. Ashizawa, and F. Matsuno, “Semi-autonomous multi-legged robot with suckers to climb a wall,” J. Robot. Mechatron., Vol.30, No.1, pp. 24-32, 2018.

- [23] Y. Matsumoto, I. Kurashige, and K. Yoneda, “Development of concrete inspection robot with dual stage suckers,” J. Robot. Mechatron., Vol.31, No.6, pp. 816-826, 2019.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.