Paper:

Proposal of Manufacturing Method for New Passive Elastic Joint and Prototype of Human Phantom

Masahiro Ikeda, Ryuma Niiyama, and Yasuo Kuniyoshi

Graduate School of Information Science and Technology, The University of Tokyo

7-3-1 Hongo, Bunkyo-ku, Tokyo 113-8656, Japan

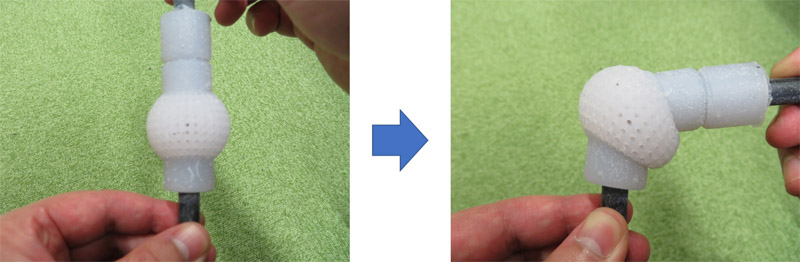

Fabricating a soft robot using conventional molding methods is difficult and time-consuming. Moreover, the types of materials used in the process are limited, and the elasticity cannot be changed incrementally. In this paper, we explain the detailed process of manufacturing molds for silicone joints. We construct a prototype molded silicone joint. We measure the elastic modulus of this joint and confirm that the elastic modulus and anisotropy change depending on the density, size, and arrangement of the surface grooves in the mold. We also develop a prototype human phantom using the proposed joint. We aim to contribute to the medical field by applying new techniques made possible by soft robotics.

Passive flexible joints molded in silicone

- [1] D. Towner, M. A. Castro, E. Eby-Wilkens, and W. M. Gilbert, “Effect of mode of delivery in nulliparous women on neonatal intracranial injury,” New England J. of Medicine, Vol.341, No.23, pp. 1709-1714, 1999.

- [2] A. Vacca, “The trouble with vacuum extraction,” Current Obstetrics & Gynaecology, Vol.9, No.1, pp. 41-45, 1999.

- [3] R. Johanson and V. Menon, “Vacuum extraction versus forceps for assisted vaginal delivery,” Cochrane Database of Systematic Reviews, doi: 10.1002/14651858.CD000224, 1999.

- [4] Y. Cheong, H. Abdullahi, H. Lashen, and F. Fairlie, “Can formal education and training improve the outcome of instrumental delivery?,” European J. of Obstetrics and Gynecology and Reproductive Biology, Vol.113, No.2, pp. 139-144, 2004.

- [5] O. Dupuis, E. Decullier, J. Clerc, R. Moreau, M.-T. Pham, S. Bin-Dorel, X. Brun, M. Berland, and T. Redarce, “Does forceps training on a birth simulator allow obstetricians to improve forceps blade placement?,” European J. of Obstetrics & Gynecology and Reproductive Biology, Vol.159, No.2, pp. 305-309, 2011.

- [6] L. M. Dubowitz, V. Dubowitz, and C. Goldberg, “Clinical assessment of gestational age in the newborn infant,” The J. of Pediatrics, Vol.77, No.1, pp. 1-10, 1970.

- [7] A. Albu-Schaffer, O. Eiberger, M. Grebenstein, S. Haddadin, C. Ott, T. Wimbock, S. Wolf, and G. Hirzinger, “Soft robotics,” IEEE Robotics and Automation Magazine, Vol.15, No.3, pp. 20-30, 2008.

- [8] K. Suzumori, “New Robotics Pioneered by Fluid Power,” J. Robot. Mechatron., Vol.32, No.5, pp. 854-862, doi: 10.20965/jrm.2020.p0854, 2020.

- [9] G. M. Whitesides, “Soft Robotics,” Angewandte Chemie Int. Edition, Vol.57, No.16, pp. 4258-4273, 2018.

- [10] W. Zhao, Y. Zhang, and N. Wang, “Soft Robotics: Research, Challenges, and Prospects,” J. Robot. Mechatron., Vol.33, No.1, pp. 45-68, doi: 10.20965/jrm.2021.p0045, 2021.

- [11] A. Ueno, V. Hlaváč, I. Mizuuchi, and M. Hoffmann, “Touching a Human or a Robot? Investigating Human-likeness of a Soft Warm Artificial Hand,” 2020 29th IEEE Int. Conf. on Robot and Human Interactive Communication (RO-MAN), pp. 14-20, 2020.

- [12] R. Niiyama, H. Sato, K. Tsujimura, K. Narumi, Y. A. Seong, R. Yamamura, Y. Kakehi, and Y. Kawahara, “poimo: Portable and Inflatable Mobility Devices Customizable for Personal Physical Characteristics,” Proc. of the 33rd Annual ACM Symp. on User Interface Software and Technology (UIST’20), pp. 912-923, 2020.

- [13] Y. A. Seong, R. Niiyama, Y. Kawahara, and Y. Kuniyoshi, “Low-pressure Soft Inflatable Joint Driven by Inner Tendon,” 2019 2nd IEEE Int. Conf. on Soft Robotics (RoboSoft), pp. 37-42, 2019.

- [14] A. D. Marchese, R. K. Katzschmann, and D. Rus, “Whole arm planning for a soft and highly compliant 2D robotic manipulator,” 2014 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 554-560, 2014.

- [15] B. Mosadegh, P. Polygerinos, C. Keplinger, S. Wennstedt, R. F. Shepherd, U. Gupta, J. Shim, K. Bertoldi, C. J. Walsh, and G. M. Whitesides, “Pneumatic networks for soft robotics that actuate rapidly,” Advanced Functional Materials, Vol.24, No.15, pp. 2163-2170, 2014.

- [16] Y. Xia and G. M. Whitesides, “Soft lithography,” Annual Review of Materials Science, Vol.28, No.1, pp. 153-184, 1998.

- [17] A. D. Marchese, R. K. Katzschmann, and D. Rus, “A recipe for soft fluidic elastomer robots,” Soft Robotics, Vol.2, No.1, pp. 7-25, 2015.

- [18] F. R. Sias, “Lost-wax Casting: Old, New, and Inexpensive Methods,” Woodsmere Press, 2005.

- [19] H. Zhao, Y. Li, A. Elsamadisi, and R. Shepherd, “Scalable manufacturing of high force wearable soft actuators,” Extreme Mechanics Letters, Vol.3, pp. 89-104, 2015.

- [20] B. Trimmer, J. A. Lewis, R. F. Shepherd, and H. Lipson, “3D printing soft materials: What is possible?,” Soft Robotics, Vol.2, No.1, pp. 3-6, 2015.

- [21] R. L. Truby and J. A. Lewis, “Printing soft matter in three dimensions,” Nature, Vol.540, No.7633, pp. 371-378, 2016.

- [22] B. N. Peele, T. J. Wallin, H. Zhao, and R. F. Shepherd, “3D printing antagonistic systems of artificial muscle using projection stereolithography,” Bioinspiration & Biomimetics, Vol.10, Article No.055003, 2015.

- [23] H. K. Yap, H. Y. Ng, and C.-H. Yeow, “High-force soft printable pneumatics for soft robotic applications,” Soft Robotics, Vol.3, No.3, pp. 144-158, 2016.

- [24] D. Drotman, S. Jadhav, M. Karimi, P. Dezonia, and M. T. Tolley, “3D printed soft actuators for a legged robot capable of navigating unstructured terrain,” 2017 IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 5532-5538, 2017.

- [25] N. W. Bartlett, M. T. Tolley, J. T. Overvelde, J. C. Weaver, B. Mosadegh, K. Bertoldi, G. M. Whitesides, and R. J. Wood, “A 3D-printed, functionally graded soft robot powered by combustion,” Science, Vol.349, No.6244, pp. 161-165, 2015.

- [26] R. MacCurdy, J. Lipton, S. Li, and D. Rus, “Printable programmable viscoelastic materials for robots,” 2016 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 2628-2635, 2016.

- [27] C. E. Eaton, T. Ramdhoni, and R. S. Karp, “Exploring Structural Control of Stiffness in Synthetic Tendon,” The 22nd Int. Conf. on Climbing and Walking Robots and Support Technologies for Mobile Machines (CLAWAR 2019), pp. 5532-5538, 2019.

- [28] Y. Yamada, H. Kanazawa, S. Iwasaki, Y. Tsukahara, O. Iwata, S. Yamada, and Y. Kuniyoshi, “An embodied brain model of the human foetus,” Scientific Reports, Vol.6, No.1, Article No.27893, 2016.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.