Development Report:

Adaptation of a Small Robot for Paddy Fields to the Water Depth Change Using Variable Legs

Kentaro Kameyama and Takuya Wada

Division of Mechanical Engineering, National Institute of Technology, Fukui College

Geshi, Sabae, Fukui 916-8507, Japan

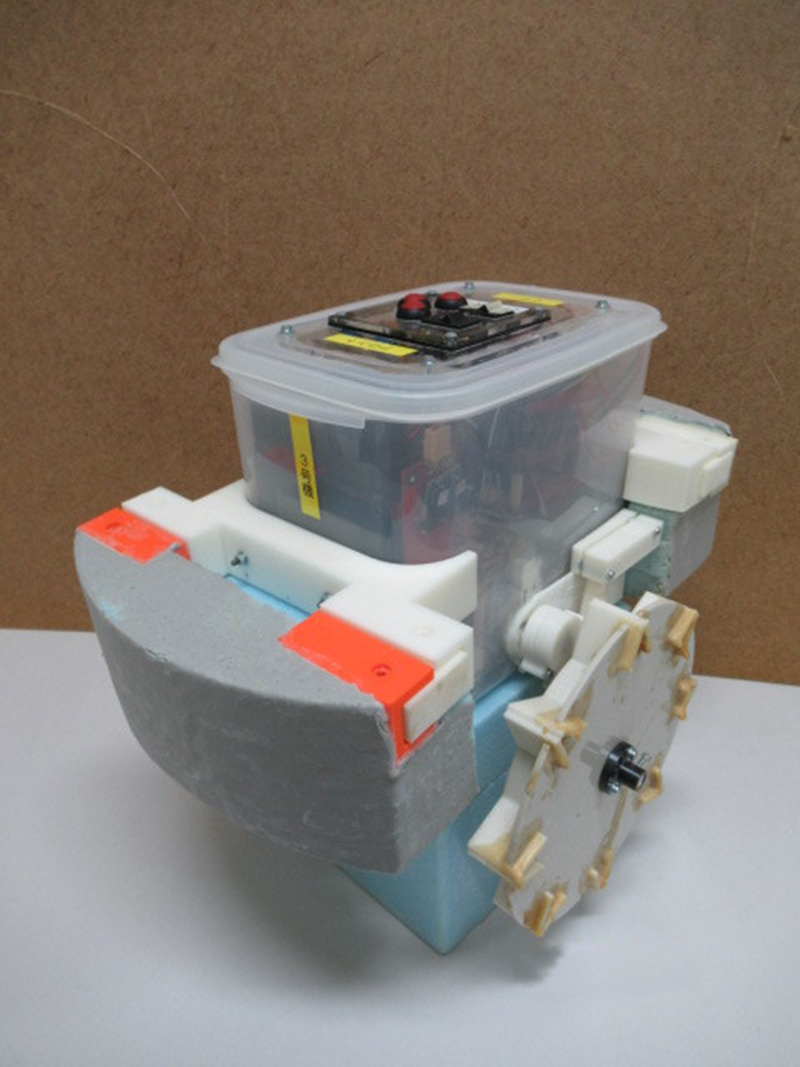

In this study, the authors conduct an operational test of a small weeding robot in paddy fields, and classify its behavioral incapacitations into two groups. Furthermore, the authors propose a leg structure for overcoming a sudden increase in water depth, one of the main causes of incapacitation. The robot is a two-wheeled vehicle with balance floats in the front and rear of the body, and the proposed structure enables the wheels to reach the ground by deforming the legs holding the wheels (variable-leg). The variable-leg robot is compared with a fixed-leg robot via a water tank experiment. It is verified that the variable-leg model can run at water depths of up to 180 mm, whereas the fixed-leg model can only run at water depths of approximately 80 mm. Furthermore, the variable-leg robot can adapt to dynamically changing water depths, as demonstrated by running over a hole.

Small robot for paddy fields with variable-legs

- [1] M. Saito, Y. Nagasaka, K. Tamaki, and K. Kobayashi, “Paddy Weeding Using an Autonomous Rice Transplanting Robot: Evaluation of Traveling Accuracy and Effect on Seedlings,” J. of the Japanese Society of Agricultural Machinery, Vol.72, pp. 276-282, 2010 (in Japanese).

- [2] Y. Miyahara, K. Tosaki, T. Ichikawa, F. Kuroiwa, and M. Orimoto, “Development of a High-Precision Weeder for Paddy Fields (1st Report),” J. of the Japanese Society of Agricultural Machinery, Vol.63, pp. 37-38, 2001 (in Japanese).

- [3] Y. Miyahara, T. Kanuma, T. Ichikawa, M. Matsuoka, and M. Orimoto, “Development of a High-Precision Weeder for Paddy Fields (2nd Report),” J. of the Japanese Society of Agricultural Machinery, Vol.64, pp. 47-48, 2002 (in Japanese).

- [4] M. Orimoto, M. Matsuoka, Y. Miyahara, T. Kanuma, and T. Ichikawa, “Development of a High-Precision Weeder for Paddy Fields (3rd Report),” J. of the Japanese Society of Agricultural Machinery, Vol.65, pp. 77-78, 2003 (in Japanese).

- [5] H. Sori, H. Inoue, H. Hatta, and Y. Ando, “Effect for a Paddy Weeding Robot in Wet Rice Culture,” J. Robot. Mechatron., Vol.30, No.2, pp. 198-205, 2018.

- [6] K. Fujii, K. Tabata, T. Yokoyama, S. Kudomi, and Y. Endo, “Development of a Small Weeding Robot “AIGAMO ROBOT” for Paddy Fields (7th Report),” Gifu Prefectural Industrial Technology Center Research Report, Vol.17, pp. 48-51, 2015 (in Japanese).

- [7] R. Kawaguchi, “Paddy Weed Machine,” Japanese Society of Agricultural Machinery and Food Engineers, Vol.80, pp. 356-360, 2018 (in Japanese).

- [8] K. Fujii, K. Tabata, T. Yokoyama, H. Hirayu, and Y. Endo, “Development of a Small Weeding Robot “AIGAMO ROBOT” for Paddy Fields (5th Report),” Gifu Prefectural Industrial Technology Center Research Report, Vol.15, pp. 32-34, 2013 (in Japanese).

- [9] M. Seki, H. Nishida, and K. Takahashi, “Development of an Environment-Harmonized Weeding Robot System (1st Report),” J. of the Japanese Society of Agricultural Machinery, Vol.60, pp. 109-110, 1998 (in Japanese).

- [10] M. Seki, H. Nishida, K. Takahashi, and K. Kojima, “Development of an Environment-Harmonized Weeding Robot System (2nd Report),” J. of the Japanese Society of Agricultural Machinery, Vol.61, pp. 277-278, 1999 (in Japanese).

- [11] M. Seki, H. Nishida, K. Takahashi, and K. Kojima, “Development of an Environment-Harmonized Weeding Robot System (3rd Report),” J. of the Japanese Society of Agricultural Machinery, Vol.62, pp. 51-52, 2000 (in Japanese).

- [12] K. Kameyama, Y. Kakitani, S. Kimura, and K. Murashima, “Development of the Soil Sampler for the Small Moving Robot,” The Robotics and Mechatronics Conf. 2017 (ROBOMECH2017), 1A1-B01, 2017 (in Japanese).

- [13] K. Kameyama, K. Sasaki, and M. S. B. Basir, “Development of the Chemical Ingredients Sensing Robot for the Paddy Fields,” The Robotics and Mechatronics Conf. 2018 (ROBOMECH2018), 1A1-A02, 2018 (in Japanese).

- [14] K. Kameyama, T. Yasuoka, R. Kawakami, and N. Asai, “Development of the Robot to Inhibit Growth of Weeds in the Paddy Field,” The Proc. of the JSME Annual Meeting, G150031, 2012 (in Japanese).

- [15] K. Kameyama, Y. Yamada, and D. Kado, “Development of a Less Invasive Small Robot for Paddy Fields,” Joint Conf. on Environmental Engineering in Agriculture 2018, PA-21, 2018 (in Japanese).

- [16] S. Hirose, “Mechanical Design of Mobile Robot for External Environments,” J. of the Robotics Society of Japan, Vol.18, pp. 904-908, 2000 (in Japanese).

- [17] Committee for Tire Design Guidelines, the Japanese Society for Terramechanics, “Terramechanics Library 1: Off-road Tire Engineering – Fundamentals of Design and Performance Prediction –,” Proc. of the Japanese Society for Terramechanics, Kyoto, 1999 (in Japanese).

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.