Paper:

Attractive Force Estimation of a Magnetic Adsorption Unit for Inspection UAVs

Yoshiyuki Higashi, Kenta Yamazaki, Arata Masuda, Nanako Miura, and Yuichi Sawada

Kyoto Institute of Technology

Goshokaido-cho, Matsugasaki, Sakyo-ku, Kyoto 606-8585, Japan

This paper presents an attractive force estimation system and an automatic activation system for an electropermanent magnet (EPM) for an inspection UAV. Adsorption to infrastructures for inspection at a distance is extremely difficult to perform safely because the operator cannot detect the state of adsorption of the drone equipped with a magnetic adsorption device. Therefore, in this paper, we clarify the relationship between the magnetic flux density and attractive force of the EPM through experiments, and develop an estimation algorithm for the attractive force based on the results. An automatic activation system, using the induced voltage in the coil when the EPM approaches the magnetic substance, is developed and mounted on a quadrotor for a flight experiment along with the estimation system for the attractive force. The developed system is verified using flight and adsorption experiments on the quadrotor.

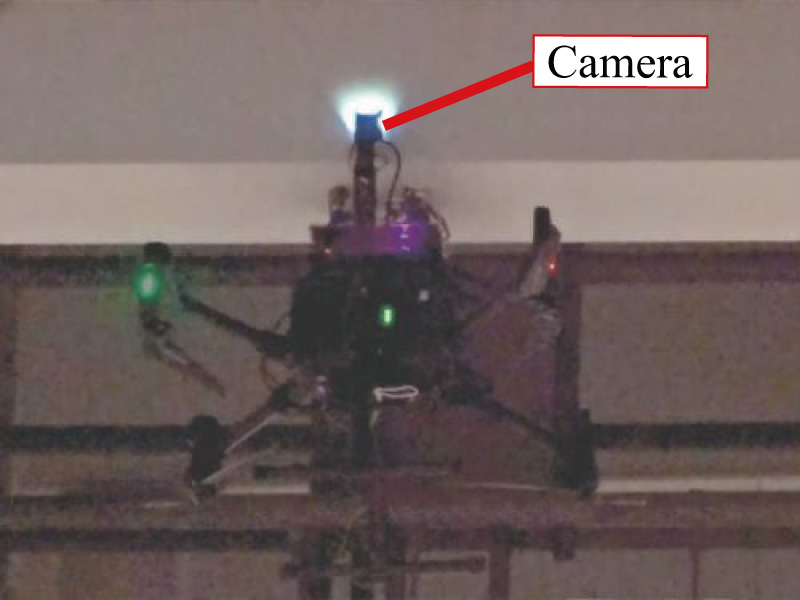

Inspection drone adsorbing on the steel beam

- [1] T. Iwamoto, T. Enaka, and K. Tada, “Development of testing machine for tunnel inspection using multi-rotor UAV,” J. of Physics: Conference Series, Vol.842, 012068, 2017.

- [2] C. Kanellakis, E. Fresk, S. S. Mansouri, D. Kominiak, and G. Nikolakopoulos, “Towards Visual Inspection of Wind Turbines: A Case of Visual Data Acquisition Using Autonomous Aerial Robots,” IEEE Access, Vol.8, pp. 181650-181661, 2020.

- [3] S. Gallardo-Saavedra, L. Hernández-Callejo, and O. Duque-Perez, “Image Resolution Influence in Aerial Thermographic Inspections of Photovoltaic Plants,” IEEE Trans. on Industrial Informatics, Vol.14, Issue 12, pp. 5678-5686, 2018.

- [4] M. Ryll, G. Muscio, F. Pierri, E. Cataldi, G. Antonelli, F. Caccavale, and A. Franchi, “6D physical interaction with a fully actuated aerial robot,” Proc. of 2017 IEEE Int. Conf. on Robotics and Automation (ICRA), 17057723, 2017.

- [5] J. Zha, X. Wu, J. Kroeger, N. Perez, and M. W. Mueller, “A collision-resilient aerial vehicle with icosahedron tensegrity structure,” Proc. of 2020 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 1407-1412, 2019.

- [6] D.-Q. Chen, X.-H. Guo, P. Huang, and F.-H. Li, “Safety Distance Analysis of 500kV Transmission Line Tower UAV Patrol Inspection,” IEEE Letters on Electromagnetic Compatibility Practice and Applications, Vol.2, Issue 4, pp. 124-128, 2020.

- [7] A. Suarez, A. Caballero, A. Garofano, P. J. Sanchez-Cuevas, G. Heredia, and A. Ollero, “Aerial Manipulator With Rolling Base for Inspection of Pipe Arrays,” IEEE Access, Vol.8, pp. 162516-162532, 2020.

- [8] M. Tognon et al., “A Truly-Redundant Aerial Manipulator System With Application to Push-and-Slide Inspection in Industrial Plants,” IEEE Robotics and Automation Letters, Vol.4, No.2, pp. 1846-1851, 2019.

- [9] S. Du, H. Chen, Y. Liu, and R. Hu, “Unified Switching between Active Flying and Perching of a Bioinspired Robot Using Impedance Control,” J. of Robotics, 763710, 2015.

- [10] K. Yanagimura, K. Ohno, Y. Okada, E. Takeuchi, and S. Tadokoro “Hovering of MAV by Using Magnetic Adhesion and Winch Mechanisms,” J. of the Robotics Society of Japan, Vol.37, No.6, pp. 514-522, 2019.

- [11] S. Shimahara, R. Ladig, S. Leewiwatwong, S. Hirai, and K. Shimonomura, “Aerial manipulation for the workspace above the airframe,” Proc. of 2015 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems (IROS), pp. 1453-1458, 2015.

- [12] S. Akahori, Y. Higashi, A. Masuda, and K. Takeuchi, “Development of a Vibration Probe Foot Using an EPM for Aerial Inspection Robots,” Proc. of 10th Int. Symp. on Advanced Science and Technology in Experimental Mechanics (ISEM’13), No.055, 2015.

- [13] S. Akahori, Y. Higashi, and A. Masuda, “Development of an Aerial Inspection Robot with EPM and Camera Arm for Steel Structures,” Proc. of 2016 IEEE Region 10 Conf. (TENCON), pp. 3542-3545, 2016.

- [14] Y. Higashi, S. Akahori, A. Masuda, and K. Takeuchi, “Verification of an EPM system for an Aerial Inspection Robot and Close-up Image Shooting,” Advanced Experimental Mechanics, Vol.1, pp. 179-184, 2016.

- [15] K. Takeuchi, A. Masuda, S. Akahori, Y. Higashi, and N. Miura, “A close inspection and vibration sensing aerial robot for steel structures with an EPM-based landing device,” Proc. of Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure 2017, 101692U, 2017.

- [16] A. Masuda, A. Tanaka, Y. Higashi, and N. Miura, “Reliable Activation of an EPM-Based Clinging Device for Aerial Inspection Robots,” J. Robot. Mechatron., Vol.31, No.6, pp. 827-836, 2019.

- [17] K. Yamazaki, Y. Higashi, A. Masuda, and N. Miura, “Improvement of Adsorption Force of an EPM-based Adsorb Device by a Suspension,” Proc. of 2020 IEEE Region 10 Conf. (TENCON), pp. 1182-1186, 2020.

- [18] A. N. Knaian, “Electropermanent Magnetic Connectors and Actuators: Devices and Their Application in Programmable Matter,” Ph.D. Thesis, Massachusetts Institute of Technology, 2010.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.