Paper:

Fabrication of Microneedle from Stretched Biodegradable Polymer Sheet by 3D Laser Machining

Seiji Aoyagi*, Junya Sato**, Tomokazu Takahashi*, Masato Suzuki*, and Shinichi Matsumoto***

*Kansai University

3-3-35 Yamate-cho, Suita, Osaka 564-8680, Japan

**Murata Machinery Ltd.

2 Nakajima, Hashizume, Inuyama-shi, Aichi 484-8502, Japan

***Sanei Seiki Co., Ltd.

2-30-16 Yaguchi, Ota-ku, Tokyo 146-0093, Japan

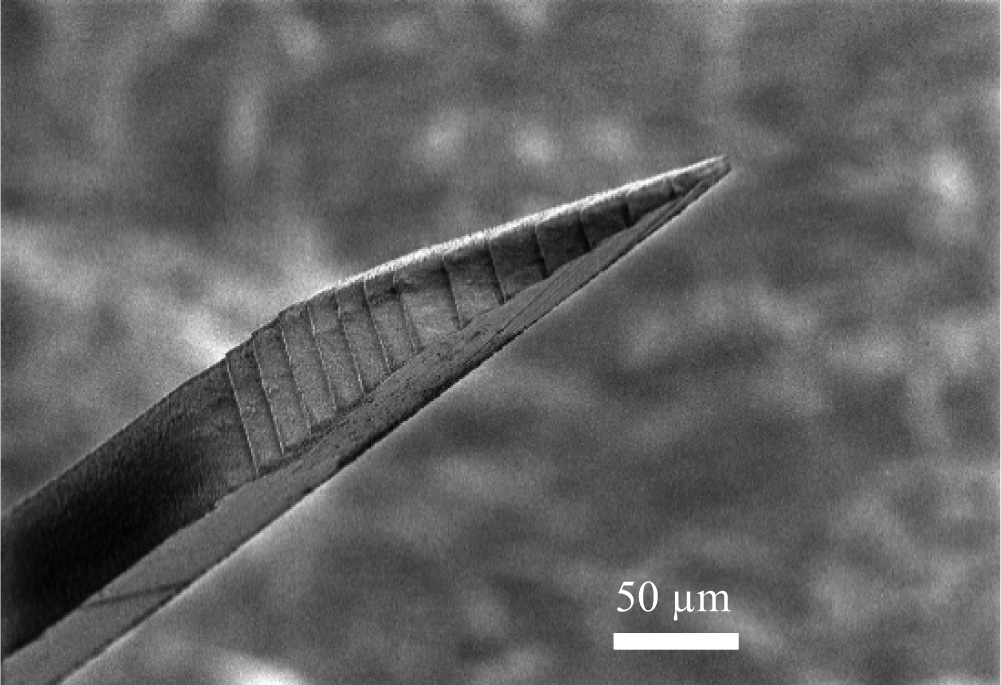

Polylactic acid (PLA) microneedles have been usually fabricated by injection molding. Herein, we consider microneedles that mimic the maxillae of mosquito proboscises, which have sharp tips with jagged harpoon-like protrusions. In case of such microneedles, filling the melting PLA resin up to the tip of the mold trough without burrs is challenging. To address this issue, we have proposed a new microneedle fabrication method in this paper. In this method, the needle with the desired shape was obtained from a PLA sheet by femtosecond laser machining. The needle was turned by 90°, and its tip further cut obliquely with the laser for three-dimensional (3D) sharpening. Tensile and buckling tests were conducted by using a test piece cut out from the PLA sheet. It was experimentally established that the strength and Young’s modulus along the sheet’s stretch direction are higher than those along its perpendicular direction. The 3D sharpened PLA microneedle successfully penetrated an artificial skin made of polydimethylsiloxane. A pair of microneedles were alternately vibrated against each other, mimicking the motion of mosquito two maxillae. With this alternate vibration, the resistance force during insertion was found to be lower compared to that without vibration.

3D sharp microneedle cut out from 50 μm-thick PLA sheet

- [1] R. S. Woodworth and H. Schlosberg, “Experimental Psychology,” Rinehart and Winston, 1965.

- [2] S. Aoyagi, “Overview of microneedles,” J. Japan Soc. Prec. Eng., Vol.82, No.12, pp. 999-1004, 2016 (in Japanese).

- [3] N. Roxhed, T. C. Gasser, P. Griss, G. A. Holzapfel, and G. Stemme, “Penetration-enhanced utrasharp microneedles and prediction on skin interaction for efficient transdermal drug delivery,” J. MEMS, Vol.16, No.6, pp. 1429-1440, 2007.

- [4] S. Henry, D. V. McAllister, M. G. Allen, and M. R. Prausnitz, “Micromachined needles for the transdermal delivery of drugs,” Proc. MEMS’98, pp. 494-498, 1998.

- [5] S. J. Moon and S. S. Lee, “Fabrication of microneedle array using inclined LIGA process,” Proc. Transducers’03, pp. 1546-1549, 2003.

- [6] H. Yagyu, S. Hayashi, and O. Tabata, “Fabrication of plastic micro tip array using laser micromachining of nanoparticles dispersed polymer and micromolding,” IEEJ Trans. Sensors and Micromachines, Vol.126, No.1, pp. 7-13, 2006.

- [7] K. Imaeda, K. Bessho, and M. Shikida, “Sharp tip-separable microneedle device for trans-dermal drug delivery systems,” Proc. Transducers 2015, pp. 1715-1718, 2015.

- [8] K. Oka, S. Aoyagi, Y. Arai, Y. Isono, G. Hashiguchi, and H. Fujita, “Fabrication of a micro needle for a trace blood test,” Sensors and Actuators, Vol.A97-98, pp. 478-485, 2002.

- [9] H. Izumi and S. Aoyagi, “Novel fabrication method for long silicon microneedles with three-dimensional sharp tips and complicated shank shapes by isotropic dry etching,” Trans. Electrical and Electronic Eng., Vol.2, No.3, pp. 328-334, 2007.

- [10] H. Izumi, Y. Yajima, S. Aoyagi, T. Tagawa, Y. Arai, M. Hirata, and S. Yorifuji, “Combined harpoonlike jagged microneedles imitating mosquito’s proboscis and its insertion experiment with vibration,” Trans. Electrical and Electronic Eng., Vol.3, pp. 425-431, 2008.

- [11] H. Izumi, M. Suzuki, S. Aoyagi, and T. Kanzaki, “Realistic imitation of mosquito’s proboscis: Electrochemically etched sharp and jagged needles and their cooperative inserting motion,” Sensors and Actuators, Vol.A165, No.1, pp. 115-123, 2011.

- [12] S. Aoyagi, H. Izumi, T. Aoki, and M. Fukuda, “Development of micro lancet needle made of biodegradable polymer for medical treatment,” IEEJ Trans. EIS, Vol.127E, No.2, pp. 53-62, 2007 (in Japanese).

- [13] S. Aoyagi, H. Izumi, and M. Fukuda, “Biodegradable polymer needle with various tip angles and consideration on insertion mechanism of mosquito’s proboscis,” Sensors and Actuators, Vol.A143, No.1, pp. 20-28, 2008.

- [14] S. Aoyagi, H. Izumi, Y. Isono, M. Fukuda, and H. Ogawa, “Laser fabrication of high aspect ratio thin holes on biodegradable polymer and its application to a microneedle,” Sensors and Actuators, Vol.A139, pp. 293-302, 2007.

- [15] S. Aoyagi, H. Izumi, S. Nakahara, M. Ochi, and H. Ogawa, “Laser microfabrication of long thin holes in biodegradable polymer in vacuum for preventing clogginess and its application to blood collection,” Sensors and Actuators, Vol.A145-146, No.1, pp. 464-472, 2008.

- [16] H. Gen, M. Ooishi, T. Takahashi, M. Suzuki, S. Aoyagi, S. Matsumoto, K. Suzuki, H. Ueda, Z. Haga, and H. Miyako, “Development of microneedle by injection molding using heat and cool method,” Proc. Fall Meeting of Japan Soc. Prec. Eng., pp. 829-830, 2015 (in Japanese).

- [17] J. Sato, M. Oishi, T. Takahashi, M. Suzuki, S. Aoyagi, S. Matsumoto, K. Suzuki, H. Ueda, Z. Haga, and H. Miyako, “Fabrication of microneedle combing two eaves-trough parts which imitates mosquito proboscis by injection molding of poly-lactic acid (PLA),” Proc. Fall Meeting of Japan Soc. Prec. Eng., pp. 101-102, 2016 (in Japanese).

- [18] M. Suzuki, T. Sawa, T. Takahashi, and S. Aoyagi, “Fabrication of microneedle mimicking mosquito proboscis using nanoscale 3D laser lithography system,” Int. J. Automation Technol., Vol.9, No.6, pp. 655-661, 2015.

- [19] M. Suzuki, T. Takahashi, and S. Aoyagi, “3D laser lithographic fabrication of hollow microneedle mimicking mosquitos and its characterization,” Int. J. Nanotechnology, Vol.15, No.1, pp. 157-173, 2018.

- [20] C.-H. Huang, T. Tanaka, Y. Takaoki, H. Izumi, T. Takahashi, M. Suzuki, and S. Aoyagi, “Fabrication of metallic microneedle by electroplating and sharpening of it by electrochemical etching,” IEEJ Trans. Sensors and Micromachines, Vol.131, No.11, pp. 373-380, 2011 (in Japanese).

- [21] T. Tanaka, T. Takahashi, M. Suzuki, and S. Aoyagi, “Development of minimally invasive microneedle made of tungsten – sharpening through electrochemical etching and hole processing for drawing up liquid using excimer laser –,” J. Robot. Mechatron., Vol.25, No.4, pp. 755-761, 2013.

- [22] H. Miyazaki, M. Suzuki, T. Takahashi, S. Aoyagi, and S. Matsumoto, “Machining of stainless microneedle with serrations imitating a mosquito and evaluation of its insertion to artificial skin,” Proc. Fall Meeting of Japan Soc. Prec. Eng., pp. 595-596, 2013 (in Japanese).

- [23] Y. Hara, M. Yamada, C. Tatsukawa, T. Takahashi, M. Suzuki, and S. Aoyagi, “Fabrication of stainless microneedle with laser cut sharp tip and its characterization of penetration and blood sampling performance,” Int. J. Automation Technol., Vol.10, No.6, pp. 950-957, 2016.

- [24] Y. Hara, M. Yamada, C. Tatsukawa, T. Takahashi, M. Suzuki, and S. Aoyagi, “Laser fabrication of jagged shaped stainless microneedle imitating mosquito’s maxilla,” Int. J. Automation Technol., Vol.10, No.6, pp. 958-964, 2016.

- [25] T. Ikeshouji, “The Interface between Mosquitoes and Humans,” University of Tokyo Press, 1999 (in Japanese).

- [26] A. N. Clement, “The Biology of Mosquitoes,” CABI Publishing, pp. 224-234, 2000.

- [27] J. Wang, S. Ootsuki, T. Takahashi, M. Suzuki, T. Kanzaki, Y. Kawajiri, and T. Oono, “Fabrication of artificial skin with capillary blood vessels and observation of mosquito bite and sucking blood using it,” Proc. Fall Meeting of Japan Soc. Prec. Eng., pp. 113-114, 2014 (in Japanese).

- [28] M. Ooishi, A. Kato, T. Takahashi, M. Suzuki, S. Aoyagi, M. Harada, and M. Ochi, “Observation of inner surface smoothness of mosquito labrum and evaluation of its hydrophilicity,” Proc. Fall Meeting of Japan Soc. Prec. Eng., pp. 761-762, 2015 (in Japanese).

- [29] H. Tsuji and Y. Ikada, “Poly Lactic Acid – for Medical Care, Medication, Environment –,” Kobunshi Kankoukai, Ltd., 1997 (in Japanese).

- [30] H. Urakawa and H. Ohara, “Crystallinity and molding properties of polylactic acid,” Technology Research Laboratory, Shimadzu Corp., Vol.56, No.34, pp. 163-168, 2000 (in Japanese).

- [31] K. Matsumoto, M. Ogaito, M. Kobayashi, E. Ozeki, and S. Tahara, “Stretching process of poly-l-lactic acid films and their structure and properties,” J. Soc. Mat. Sci., Japan, Vol.43, No.495, pp. 1520-1524, 1994.

- [32] M. Sakaguchi and S. Kobayashi, “Processing and characterization of poly(lactic acid) screw,” Trans. of the Japan Society of Mechanical Engineers Series A, Vol.78, No.785, pp. 95-105, 2012 (in Japanese).

- [33] J. K. Lee, K. H. Lee, and B. S. Jin, “Structure development and biodegradability of uniaxially stretched poly(Llactide),” European Polymer J., Vol.35, pp. 907-914, 2001.

- [34] P. P. Pronko, S. K. Dutta, J. Squier, J. V. Rudd, D. Du, and G. Mourou, “Machining of sub-micron holes using a femtosecond laser at 800 nm,” Opt. Commum, Vol.114, pp. 106-110, 1995.

- [35] C. Momma, B. N. Chichkov, S. Nolte, F. V. Alvensleben, A. Tiinnermann, H. Welling, and B. Wellegehausen, “Short-pulse laser ablation of solid targets,” Opt. Commum, Vol.129, pp. 134-142, 1996.

- [36] M. Fujita and M. Hashida, “Femtosecond-laser processing,” J. Plasma Fusion Res., Vol.81, pp. 195-201, 2005 (in Japanese).

- [37] M. Ogura, Y. Terada, M. Suzuki, T. Takahashi, and S. Aoyagi, “Development of puncture jig for preventing microneedle from buckling imitating labium of mosquito,” Proc. Symp. Micro-Nano Sci. and Tech., pp. 233-234, 2013 (in Japanese).

- [38] P. G. Agache, C. Monneur, J. L. Leveque, and J. D. Rigal, “Mechanical properties and Young’s modulus of human skin in vivo,” Archives of Dermatological Research, Vol.269, No.3, pp. 221-232, 1980.

- [39] F. M. Hendriks, D. Broken, J. T. W. M. van Eemeren, C. W. J. Oomens, F. P. T. Baaijens, and J. B. A. M. Horsten, “A numerical-experimental method to characterize the non-linear mechanical behaviour of human skin,” Skin Research and Technology, Vol.9. No.3, pp. 274-283, 2003.

- [40] J. F. Manschot and J. M. Brakkee, “The measurement and modelling of the mechanical properties of human skin in vivo – II. The model,” J. Biomechanics, Vol.19, No.7, pp. 517-521, 1986.

- [41] S. Yamamoto, M. Suzuki, T. Takahashi, S. Aoyagi, T. Nagashima, S. Yamaguchi, S. Imazato, A. Kunugi, and T. Saruwatari, “Confirmation of cooperative vibration effect of mosquito’s mouthpart by non-linear finite element method analysis,” Proc. Spring Meeting of Japan Soc. Prec. Eng., pp. 311-312, 2016 (in Japanese).

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.