Paper:

Shape Adaptation of the Inspection Guide Frame in Tunnels to Avoid Obstacles Detected by a Laser Range Finder

Fumihiro Inoue*, Soonsu Kwon*, Satoru Nakamura**, and Yoshitaka Yanagihara***

*Shonan Institute of Technology

1-1-25 Tsujidonishikaigan, Fujisawa-shi, Kanagawa 251-8511, Japan

**Institute of Technology, Tokyu Construction Co., Ltd.

3062-1 Tana, Chuo-ku, Sagamihara, Kanagawa 252-0244, Japan

***ICT Strategy Department, Corporate Strategy Division, Tokyu Construction Co., Ltd.

1-16-14 Shibuya, Shibuya-ku, Tokyo 150-8340, Japan

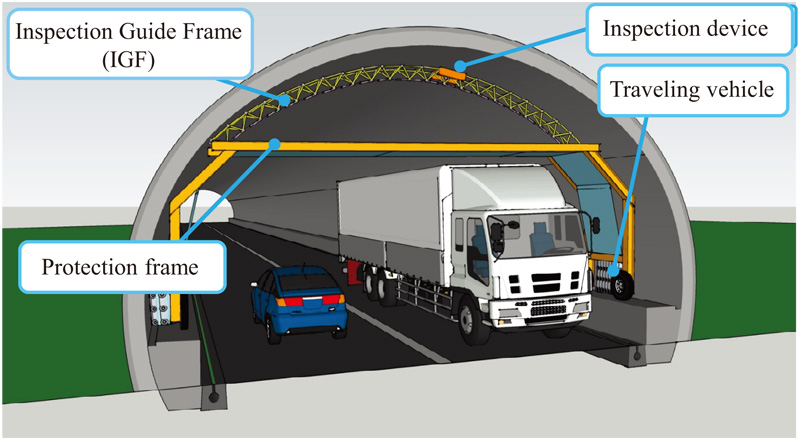

To advance the automated inspection and maintenance of the inner wall of tunnels, an advanced inspection system aimed at regulating traffic was developed. In this inspection system, a guide frame was installed along the tunnel ceiling wall that is above the protection frame built over the road and resembles a gantry crane. The inspection device was fitted with an inspection guide frame (IGF), which stabilized its movement and improved its accuracy. However, as this protection frame moves along the tunnel, the guide frame should have the capacity to avoid convex obstacles such as the duct fan, the lamp and road traffic signs within the tunnel. Therefore, the entire inspection guide frame is made of variable geometry truss (VGT), which makes it possible to suitably alter the shape of the guide frame whenever necessary and pass it through the tunnel. To enable the guide frame adapt to any shape, the inverse analysis method and mathematical interpolation method were applied. The orientation of each frame was reversely analyzed according to the shape of the obstacle measured using the laser range finder (LRF), and the frame’s actuator was controlled simultaneously. We investigated the construction of a system that can perform a series of tasks such as searching for obstacles and positioning, frame shape simulation, frame shape change, inspection of the device and movement. By applying spline interpolation, we managed to practically determine the shape of the guide frame that would avoid obstacles.

Shape adaptation of IGF to avoid obstacles in tunnels

- [1] F. Inoue and S. Nakamura, “Development of Variable Guide Frame to Inspect Inner Wall Tunnel,” Proc. of the 6th Int. Conf. on Advance Mechatronics (ICAM2015), Tokyo, Japan, pp. 284-285, 2010.

- [2] H. Fujii, A. Yamashita, and H. Asama, “Defect Detection with Estimation of Material Condition Using Ensemble Learning for Hammering Test,” Proc. of the 2016 IEEE Int. Conf. on Robotics and Automation, Stockholm (Sweden), pp. 847-3854, 2016.

- [3] J. Soh, J. Lee, and C. Han, “Development of Object Detection Technology Using Laser Sensor for Intelligent Excavation Work,” Proc. of the 26th Int. Symp. on Automation and Robotics in Construction, Austin, TX, USA, pp. 117-125, 2009.

- [4] H. Chang, J. Choi, and M. Kim, “Reliable Position Estimation Method of the Mobile Robot by Laser Scanner and Indoor GPS System,” Proc. of the 23rd Int. Symp. on Automation and Robotics in Construction, Tokyo Japan, pp. 505-510, 2006.

- [5] J. Teizer, F. Bosche, H. Carlos, and C. T. Haas, “Real-Time, Three-Dimensional Object Detection and Modelling in Construction,” Proc. of the 22nd Int. Symp. on Automation and Robotics in Construction, Ferrara, Italy, pp. 1-5, 2009.

- [6] J. Lee, C. Kim, H. Son, and C. Kim, “Automated Pipeline Extraction for Modelling from Laser Scanned Date,” Proc. of the 29th Int. Symp. on Automation and Robotics in Construction, Eindhoven, Netherlands, pp. 1-5, 2012.

- [7] R. Heikkila, M. Jaakkola, and P. Pulkkinen, “Connecting 3-D Concrete Bridge Design to 3-D Site Measurement,” Proc. of the 20th Int. Symp. on Automation and Robotics in Construction, Eindhoven Holland, pp. 259-264, 2003.

- [8] T. Makkonen, R. Heikkila, A. Kaaranka, and M. Naatsaari, “The Applicability of the Rapid Handheld Laser Scanner to Underground Tunnel Surveying,” Proc. of the 32th Int. Symp. on Automation and Robotics in Construction, Oulu, Finland, pp. 1-7, 2015.

- [9] S. Han, H. Cho, S. Kim, and J. Heo, “A Fast Automated Method for Extracting Tunnel Cross-Sections Using Terrestrial Laser Scanned Data,” Proc. of the 28th Int. Symp. on Automation and Robotics in Construction, Seoul, Korea, pp. 1013-1018, 2011.

- [10] F. Inoue, “Shape Control of Variable Guide Frame for Tunnel Wall Inspection,” Proc. of the 34th Int. Symp. on Automation and Robotics in Construction (Int. Symp. on Automation and Robotics in Construction 2017), Taipei, Taiwan, pp. 675-682, 2009.

- [11] H. Tamura, T. Sasaki, H. Hashimoto, and F. Inoue, “Circle Fitting Based Position Measurement System Using Laser Range Finder in Construction Fields,” 2010 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 209-214, 2010.

- [12] N. Chernov and C. Lesort, “Least Square Fitting of Circles,” J. of Mathematical Imaging and Vision, Vol.23, pp. 239-251, 2005.

- [13] F. Inoue, T. Sasaki, X. Huang, and H. Hashimoto, “A Study on Position Measurement System Using Laser Range Finder and Its Application for Construction Work,” J. Robot. Mechatron., Vol.26, No.1, pp. 226-234, 2012.

- [14] K. Miura, “Variable Geometry Truss Concept (Part I: Design and Operation of a Deployable Truss Structure),” The Institute of Space and Astronautical Science Report, No.614, 1984.

- [15] K. Miura, “Variable Geometry Truss Concept (Part II: Review on Special Application of Variable Geometry Truss),” The Institute of Space and Astronautical Science Report, No.614, 1984.

- [16] G. S. Chirikjian, “Binary paradigm for robotic manipulators,” Proc. of IEEE Int. Conf. on Robotics and Automation, pp. 3063-3069, 1994.

- [17] G. S. Chirikjian, “Kinematic synthesis of mechanisms and robotic manipulators with binary actuators,” J. Mech. Des., Vol.117, No.4, pp. 573-580, 1995.

- [18] F. Inoue, “A Study on Adaptive Structure Applying Variable Geometry Truss (Mechanism of Movable Arch Roof with External Panel),” J. Robot. Mechatron., Vol.21, No.2, pp. 172-178, 2009.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.