Paper:

Wheel Slip Classification Method for Mobile Robot in Sandy Terrain Using In-Wheel Sensor

Takuya Omura and Genya Ishigami

Keio University

3-14-1 Hiyoshi, Kohoku, Yokohama, Kanagawa 223-8522, Japan

This paper proposes a method that can estimate and classify the magnitude of wheel slippage for a mobile robot in sandy terrains. The proposed method exploits a sensor suite, called an in-wheel sensor, which measures the normal force and contact angle at the wheel-sand interaction boundary. An experimental test using the in-wheel sensor reveals that the maximum normal force and exit angle of the wheel explicitly vary with the magnitude of the wheel slippage. These characteristics are then fed into a machine learning algorithm, which classifies the wheel slippage into three categories: non-stuck wheel, quasi-stuck wheel, and stuck wheel. The usefulness of the proposed method for slip classification is experimentally evaluated using a four-wheel-drive test bed rover.

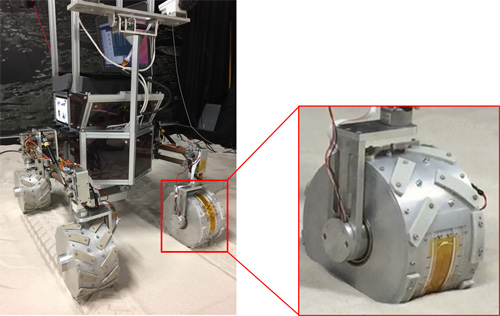

Test bed rover with in-wheel sensor

- [1] A. Angelova, L. Matthies, D. Helmick, and P. Perona, “Learning and prediction of slip from visual information,” J. of Field Robotics, Vol.24, Issue 3, pp. 205-231, 2007.

- [2] M. Maimone, Y. Cheng, and L. Matthies, “Two years of Visual Odometry on the Mars Exploration Rovers,” J. of Field Robotics, Vol.24, Issue 3, pp. 169-189, 2007.

- [3] R. Gonzalez, S. Byttner, and K. Iagnemma, “Comparison of Machine Learning Approaches for Soil Embedding Detection of Planetary Exploration Rovers,” Proc. of the 8th Americas Conf. of ISTVS, 2016.

- [4] H. Tsubaki and G. Ishigami, “Modeling of Wheel-Soil Interaction Mechanisms Based on Accurate Measurement of Pressure Distribution for Lightweight Vehicle,” Proc. of the 8th Americas Conf. of ISTVS, 2016.

- [5] J. Y. Wong, “Terramechanics and off-road vehicles,” pp. 121-137, Elsevier Science, 1989.

- [6] T. Shirai and G. Ishigami, “Development of in-wheel sensor system for accurate measurement of wheel terrain interaction characteristics,” J. of Terramechanics, Vol.62, pp. 51-61, 2015.

- [7] T. Kobayashi, Y. Fujiwara, J. Yamakawa, N. Yasufuku, and K. Omine, “Mobility performance of a rigid wheel in low gravity environments,” J. of Terramechanics, Vol.47, Issue 4, pp. 261-274, 2010.

- [8] O. Ringdal, T. Hellstrom, and O. Lindroos, “Estimating wheel slip for a forest machine using RTK-DGPS,” J. of Terramechanics, Vol.49, Issue 5, pp. 271-279, 2012.

- [9] J. B. Johnson, A. V. Kulchitsky, P. Duvoy, K. Iagnemma, C. Senatore, R. E. Arvidson, and J. Moore, “Discrete element method simulations of Mars Exploration Rover wheel performance,” J. of Terramechanics, Vol.62, pp. 31-40, 2015.

- [10] V. Vapnik and A. Lerner, “Pattern Recognition using Generalized Portrait Method,” Automation and Remote Control, Vol.24, pp. 774-780, 1963.

- [11] K. Iagnemma and C. C. Ward, “Classification-based wheel slip detection and detector fusion for mobile robots on outdoor terrain,” Autonomous Robots, Vol.26, Issue 1, pp. 33-46, 2009.

- [12] V. Vapnik, “The Nature of Statistical Learning Theory,” Springer-Verlag, 1995.

- [13] M. Sokolova and G. Lapalme, “A systematic analysis of performance measures for classification tasks,” Information Processing & Management, Vol.45, Issue 4, pp. 427-437, 2009.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.