Paper:

HFR-Video-Based Vibration Analysis of a Multi-Jointed Robot Manipulator

Tuniyazi Abudoureheman

, Feiyue Wang

, Feiyue Wang

, Kohei Shimasaki

, Kohei Shimasaki

, and Idaku Ishii

, and Idaku Ishii

Graduate School of Advanced Science and Engineering, Hiroshima University

1-4-1 Kagamiyama, Higashi-hiroshima, Hiroshima 739-8527, Japan

As the demand for industrial robots continues to increase, monitoring robot manipulators in factory environments has become essential to ensure proper and precise operation. Unexpected vibrations can reduce the production efficiency and quality, causing financial losses, and safety risks to workers. Evaluating a robot’s vibration resistance solely through arm movements makes it challenging to accurately capture fine vibration-frequency responses using conventional methods. Traditional analyses rely on contact sensors, which are limited by the number of measurable points, and often involve high costs. In this study, we employed high-frame-rate (HFR) cameras for non-contact vibration analysis, enabling a detailed evaluation of the vibration characteristics during robot operation. By processing the 500 fps HFR video using digital image correlation, we analyzed the frequency responses of sub-pixel displacements at multiple locations and quantified changes in the vibration amplitude and phase across different parts of the robot. This approach provides a more precise understanding of fine vibration distributions and their impacts. The proposed method is accurate and can simultaneously measure multiple points.

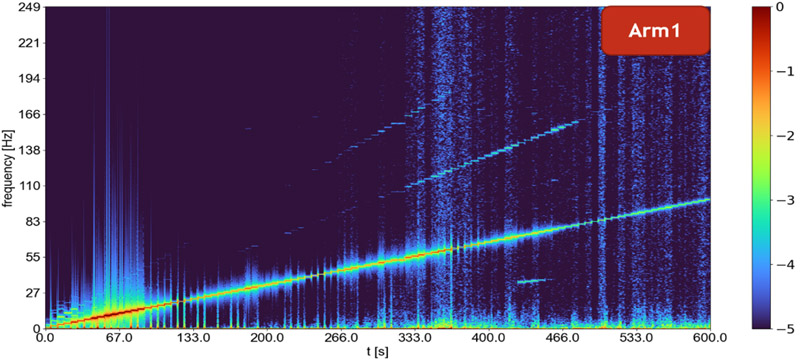

Power spectograms of output/input ratio

- [1] B. Tipary, A. Kovács, and F. G. Erdős, “Planning and optimization of robotic pick-and-place operations in highly constrained industrial environments,” Assembly Automation, Vol.41, Issue 5, pp. 626-639, 2021. https://doi.org/10.1108/AA-07-2020-0099

- [2] D. Liu and J. Fang, “Vibration reduction of flexible fruit picking robot by adaptive input shaping method,” 2016 Int. Conf. on Advanced Mechatronic Systems (ICAMechS), pp. 169-173, 2016. https://doi.org/10.1109/ICAMechS.2016.7813441

- [3] R. Hiraoka, K. Kobayashi, and Y. Aoyagi, “Simulation of vibration caused by an automatic transporter on harvested products,” 2022 Joint 12th Int. Conf. on Soft Computing and Intelligent Systems and 23rd Int. Symp. on Advanced Intelligent Systems (SCIS&ISIS), 2022. https://doi.org/10.1109/SCISISIS55246.2022.10001905

- [4] C. G. Cooley and R. G. Parker, “A Review of Planetary and Epicyclic Gear Dynamics and Vibrations Research,” Applied Mechanics Reviews, Vol.66, Issue 4, Article No.040804, 2014. https://doi.org/10.1115/1.4027812

- [5] M. Romanssini, P. C. C. de Aguirre, L. Compassi-Severo, and A. G. Girardi, “A Review on Vibration Monitoring Techniques for Predictive Maintenance of Rotating Machinery,” Eng, Vol.4, Issue 3, pp. 1797-1817, 2023. https://doi.org/10.3390/eng4030102

- [6] C. S. Franklin, E. G. Dominguez, J. D. Fryman, and M. L. Lewandowski, “Collaborative robotics: New era of human-robot cooperation in the workplace,” J. of Safety Research, Vol.74, pp. 153-160, 2020. https://doi.org/10.1016/j.jsr.2020.06.013

- [7] R. Natarajan, S. Reddy P, S. C. Bose, H. L. Gururaj, F. Flammini, and S. Velmurugan, “Fault detection and state estimation in robotic automatic control using machine learning,” Array, Vol.19, Article No.100298, 2023. https://doi.org/10.1016/j.array.2023.100298

- [8] W. Zhang and J. Zhou, “Fault Diagnosis for Rolling Element Bearings Based on Feature Space Reconstruction and Multiscale Permutation Entropy,” Entropy, Vol.21, Issue 5, Article No.519, 2019. https://doi.org/10.3390/e21050519

- [9] L. Zhang, Y. Li, L. Dong, X. Yang, X. Ding, Q. Zeng, L. Wang, and Y. Shao, “Gearbox Fault Diagnosis Using Multiscale Sparse Frequency-Frequency Distributions,” IEEE Access, Vol.9, pp. 113089-113099, 2021. https://doi.org/10.1109/ACCESS.2021.3104281

- [10] A. H. Sabry and U. A. B. U. Amirulddin, “A review on fault detection and diagnosis of industrial robots and multi-axis machines,” Results in Engineering, Vol.23, Article No.102397, 2024. https://doi.org/10.1016/j.rineng.2024.102397

- [11] A. P. Daga and L. Garibaldi, “Machine Vibration Monitoring for Diagnostics through Hypothesis Testing,” Information, Vol.10, Issue 6, Article No.204, 2019. https://doi.org/10.3390/info10060204

- [12] S. Shao, S. McAleer, R. Yan, and P. Baldi, “Highly Accurate Machine Fault Diagnosis Using Deep Transfer Learning,” IEEE Trans. on Industrial Informatics, Vol.15, Issue 4, pp. 2446-2455, 2019. https://doi.org/10.1109/TII.2018.2864759

- [13] Y. Kim, J. Park, K. Na, H. Yuan, B. D. Youn, and C.-s. Kang, “Phase-based time domain averaging (PTDA) for fault detection of a gearbox in an industrial robot using vibration signals,” Mechanical Systems and Signal Processing, Vol.138, Article No.106544, 2020. https://doi.org/10.1016/j.ymssp.2019.106544

- [14] A. A. Jaber and R. Bicker, “Design of a Wireless Sensor Node for Vibration Monitoring of Industrial Machinery,” Int. J. of Electrical and Computer Engineering (IJECE), Vol.6, No.2, pp. 639-653, 2016. https://doi.org/10.11591/ijece.v6i2.9296

- [15] H. Khan, M. D’Imperio, F. Cannella, D. G. Caldwell, A. Cuschieri, and C. Semini, “Towards Scalable Strain Gauge-Based Joint Torque Sensors,” Sensors, Vol.17, Issue 8, Article No.1905, 2017. https://doi.org/10.3390/s17081905

- [16] Y. Chen, X. Zheng, Y. Luo, Y. Shen, Y. Xue, and W. Fu, “An Approach for Time Synchronization of Wireless Accelerometer Sensors Using Frequency-Squeezing-Based Operational Modal Analysis,” Sensors, Vol.22, Issue 13, Article No.4784, 2022. https://doi.org/10.3390/s22134784

- [17] D. A. Elvira-Ortiz, R. de. J. Romero-Troncoso, A. Y. Jaen-Cuellar, L. Morales-Velazquez, and R. A. Osornio-Rios, “Vibration Suppression for Improving the Estimation of Kinematic Parameters on Industrial Robots,” Shock and Vibration, 2016. https://doi.org/10.1155/2016/6954012

- [18] I. Ishii, T. Tatebe, Q. Gu, Y. Moriue, T. Takaki, and K. Tajima, “2000 fps real-time vision system with high-frame-rate video recording,” 2010 IEEE Int. Conf. on Robotics and Automation, pp. 1536-1541, 2010. https://doi.org/10.1109/ROBOT.2010.5509731.

- [19] Y. Watanabe, T. Komuro, and M. Ishikawa, “955-fps Real-time Shape Measurement of a Moving/Deforming Object Using High-speed Vision for Numerous-point Analysis,” Proc. of 2007 IEEE Int. Conf. on Robotics and Automation, pp. 3192-3197, 2007. https://doi.org/10.1109/ROBOT.2007.363965

- [20] J. Luo, B. Liu, P. Yang, and X. Fan, “High-speed vision measurement of vibration based on an improved ZNSSD template matching algorithm,” Systems Science & Control Engineering, Vol.10, Issue 1, pp. 43-54, 2022. https://doi.org/10.1080/21642583.2021.2024099

- [21] D. K. Thomsen, R. Søe-Knudsen, O. Balling, and X. Zhang, “Vibration control of industrial robot arms by multi-mode time-varying input shaping,” Mechanism and Machine Theory, Vol.155, Article No.104072, 2021. https://doi.org/10.1016/j.mechmachtheory.2020.104072

- [22] F. L. M. dos Santos, B. Peeters, J. Lau, W. Desmet, and L. C. S. Goes, “The use of strain gauges in vibration-based damage detection,” J. of Physics: Conf. Series, Vol.628, Article No.012119, 2015. https://doi.org/10.1088/1742-6596/628/1/012119

- [23] D. Rovšček, J. Slavič, and M. Boltežar, “The use of strain sensors in an experimental modal analysis of small and light structures with free-free boundary conditions,” J. of Vibration and Control, Vol.19, Issue 7, pp. 1072-1079, 2013. https://doi.org/10.1177/1077546312445058

- [24] S. Miyabe, N. Ono, and S. Makino, “Blind compensation of inter-channel sampling frequency mismatch with maximum likelihood estimation in STFT domain,” 2013 IEEE Int. Conf. on Acoustics, Speech and Signal Processing, pp. 674-678, 2013. https://doi.org/10.1109/ICASSP.2013.6637733

- [25] R. P. Linessio, K. de M. Sousa, T. da Silva, C. A. Bavastri, P. F. da C. Antunes, and J. C. C. da Silva, “Induction Motors Vibration Monitoring Using a Biaxial Optical Fiber Accelerometer,” IEEE Sensors J., Vol.16, Issue 22, pp. 8075-8082, 2016. https://doi.org/10.1109/JSEN.2016.2604850

- [26] S. Nakamura, Y. Higashi, A. Masuda, and A. Tanaka, “Development of Vibration Measurement Unit for Steel Structure Using MEMS Accelerometer,” 2018 IEEE Region 10 Conf. (TENCON 2018), pp. 587-592, 2018. https://doi.org/10.1109/TENCON.2018.8650363

- [27] A. Gude, S. Pawar, S. Alhat, and S. Mishra, “Vibration Analysis for Engine fault Detection,” J. of Robotics and Control (JRC), Vol.2, No.3, 2021. https://doi.org/10.18196/jrc.2379

- [28] S. H. Gawande and R. R. More, “Effect of Notch Depth & Location on Modal Natural Frequency of Cantilever Beams,” Structures, Vol.8, Part 1, pp. 121-129, 2016. https://doi.org/10.1016/j.istruc.2016.09.003

- [29] D. Feng and M. Q. Feng, “Identification of structural stiffness and excitation forces in time domain using noncontact vision-based displacement measurement,” J. of Sound and Vibration, Vol.406, pp. 15-28, 2017. https://doi.org/10.1016/j.jsv.2017.06.008

- [30] D. L. Brown, R. J. Allemang, and A. W. Phillips, “Forty Years of Use and Abuse of Impact Testing: A Practical Guide to Making Good FRF Measurements,” J. De Clerck (Ed.), “Experimental Techniques, Rotating Machinery, and Acoustics, Vol.8,” pp. 221-241, River Publishers, 2015. https://doi.org/10.1007/978-3-319-15236-3_21

- [31] H. Nakagawa, Y. Kurita, K. Ogawa, Y. Sugiyama, and H. Hasegawa, “Experimental Analysis of Chatter Vibration in End-Milling Using Laser Doppler Vibrometers,” Int. J. Automation Technol., Vol.2, No.6, pp. 431-438, 2008. https://doi.org/10.20965/ijat.2008.p0431

- [32] Y. Li, E. Dieussaert, and R. Baets, “Miniaturization of Laser Doppler Vibrometers—A Review,” Sensors, Vol.22, Issue 13, Article No.4735, 2022. https://doi.org/10.3390/s22134735

- [33] P. Castellini, M. Martarelli, and E. P. Tomasini, “Laser Doppler Vibrometry: Development of advanced solutions answering to technology’s needs,” Mechanical Systems and Signal Processing, Vol.20, Issue 6, pp. 1265-1285, 2006. https://doi.org/https://doi.org/10.1016/j.ymssp.2005.11.015

- [34] J. Eichenberger and J. Sauer, “Validating Complex Models Accurately and Without Contact Using Scanning Laser Doppler Vibrometry (SLDV),” D. Di Maio and J. Baqersad (Eds.), “Rotating Machinery, Optical Methods & Scanning LDV Methods, Vol.6,” pp. 113-124, River Publishers, 2022. https://doi.org/10.1007/978-3-030-76335-0_11

- [35] G. Rossi, R. Marsili, V. Gusella, and M. Gioffrè, “Comparison Between Accelerometer and Laser Vibrometer to Measure Traffic Excited Vibrations on Bridges,” Shock and Vibration, 2002. https://doi.org/10.1155/2002/968509

- [36] K. Yuan and W. D. Zhu, “A novel general-purpose three-dimensional continuously scanning laser Doppler vibrometer system for full-field vibration measurement of a structure with a curved surface,” J. of Sound and Vibration, Vol.540, Article No.117274, 2022. https://doi.org/https://doi.org/10.1016/j.jsv.2022.117274

- [37] D. Di Maio, P. Castellini, M. Martarelli, S. Rothberg, M. S. Allen, W. D. Zhu, and D. J. Ewins, “Continuous Scanning Laser Vibrometry: A raison d’être and applications to vibration measurements,” Mechanical Systems and Signal Processing, Vol.156, Article No.107573, 2021. https://doi.org/https://doi.org/10.1016/j.ymssp.2020.107573

- [38] J. Y. Jeon, Y. Miao, G. Park, and E. Flynn, “Compressive laser scanning with full steady state wavefield for structural damage detection,” Mechanical Systems and Signal Processing, Vol.169, Article No.108626, 2022. https://doi.org/https://doi.org/10.1016/j.ymssp.2021.108626

- [39] W. Yeo and M. Matsumoto, “Fault Diagnosis Systems for Robots: Acoustic Sensing-Based Identification of Detached Components for Fault Localization,” Applied Sciences, Vol.15, Issue 12, Article No.6564, 2025. https://doi.org/10.3390/app15126564

- [40] S.-Q. Zhang, X.-Y. Zhang, H.-L. Ji, S.-S. Ying, and R. Schmidt, “A refined disturbance rejection control for vibration suppression of smart structures under unknown disturbances,” J. of Low Frequency Noise, Vibration and Active Control, Vol.40, Issue 1, pp. 427-441, 2021. https://doi.org/10.1177/1461348419875351

- [41] I. Ishii, T. Taniguchi, K. Yamamoto, and T. Takaki, “High-Frame-Rate Optical Flow System,” IEEE Trans. on Circuits and Systems for Video Technology, Vol.22, Issue 1, pp. 105-112, 2012. https://doi.org/10.1109/TCSVT.2011.2158340

- [42] F. Wang, S. Hu, K. Shimasaki, and I. Ishii, “Real-Time Vibration Visualization Using GPU-Based High-Speed Vision,” J. Robot. Mechatron., Vol.34, No.5, pp. 1011-1023, 2022. https://doi.org/10.20965/jrm.2022.p1011

- [43] K. Shimasaki, M. Jiang, T. Takaki, and I. Ishii, “Real-time Multicopter Detection Using Pixel-level Digital Filters for Frame-Interpolated High-frame-rate Images,” 2018 IEEE/ASME Int. Conf. on Advanced Intelligent Mechatronics (AIM), pp. 304-309, 2018. https://doi.org/10.1109/AIM.2018.8452345

- [44] M. Jiang, T. Aoyama, T. Takaki, and I. Ishii, “Pixel-Level and Robust Vibration Source Sensing in High-Frame-Rate Video Analysis,” Sensors, Vol.16, Issue 11, Article No.1842, 2016. https://doi.org/10.3390/s16111842

- [45] S. Cao, J. Yan, H. Nian, and C. Xu, “Full-field out-of-plane vibration displacement acquisition based on speckle-projection digital image correlation and its application in damage localization,” Int. J. of Mechanical System Dynamics, Vol.2, Issue 4, pp. 363-373, 2022. https://doi.org/10.1002/msd2.12055

- [46] M. Ye, J. Liang, L. Li, B. Qian, M. Ren, M. Zhang, W. Lu, and Y. Zong, “Full-field motion and deformation measurement of high speed rotation based on temporal phase-locking and 3D-DIC,” Optics and Lasers in Engineering, Vol.146, Article No.106697, 2021. https://doi.org/10.1016/j.optlaseng.2021.106697

- [47] S. Hu, M. Jiang, T. Takaki, and I. Ishii, “Real-Time Monocular Three-Dimensional Motion Tracking Using a Multithread Active Vision System,” J. Robot. Mechatron., Vol.30, No.3, pp. 453-466, 2018. https://doi.org/10.20965/jrm.2018.p0453

- [48] Z. Azouz, B. H. S. Asli, and M. Khan, “Potential of Non-Contact Dynamic Response Measurements for Predicting Small Size or Hidden Damages in Highly Damped Structures,” Sensors, Vol.24, Issue 18, Article No.5871, 2024. https://doi.org/10.3390/s24185871

- [49] T. J. Beberniss and D. A. Ehrhardt, “High-speed 3D digital image correlation vibration measurement: Recent advancements and noted limitations,” Mechanical Systems and Signal Processing, Vol.86, Part B, pp. 35-48, 2017. https://doi.org/https://doi.org/10.1016/j.ymssp.2016.04.014

- [50] S. F. Zettel, M. Norambuena, R. D. Dewald, and M. Böswald, “Comparison of laser Doppler vibrometry and digital image correlation measurement techniques for applications in vibroacoustics,” 29th Int. Congress on Sound and Vibration (ICSV), 2023.

- [51] D. Feng, M. Q. Feng, E. Ozer, and Y. Fukuda, “A Vision-Based Sensor for Noncontact Structural Displacement Measurement,” Sensors, Vol.15, Issue 7, pp. 16557-16575, 2015. https://doi.org/10.3390/s150716557

- [52] P. L. Reu, D. P. Rohe, and L. D. Jacobs, “Comparison of DIC and LDV for practical vibration and modal measurements,” Mechanical Systems and Signal Processing, Vol.86, Part B, pp. 2-16, 2017. https://doi.org/https://doi.org/10.1016/j.ymssp.2016.02.006

- [53] K.-H. Kim and H.-K. Jung, “Development of a Remote Displacement Measuring Laser System for Bridge Inspection,” Sensors, Vol.22, Issue 5, Article No.1963, 2022. https://doi.org/10.3390/s22051963

- [54] A. Rossi, G. Bocchetta, F. Botta, and A. Scorza, “Accuracy Characterization of a MEMS Accelerometer for Vibration Monitoring in a Rotating Framework,” Applied Sciences, Vol.13, Issue 8, Article No.5070, 2023. https://doi.org/10.3390/app13085070

- [55] X. Guo, Y. Fan, D. Liu, and H. Chen, “Vibration sensing system integrating triboelectric nanogenerator and synaptic transistor for self-powered building vibration identification,” Measurement, Vol.249, Article No.116966, 2025. https://doi.org/https://doi.org/10.1016/j.measurement.2025.116966

- [56] H. S. Park, J. M. Kim, S. W. Choi, and Y. Kim, “A Wireless Laser Displacement Sensor Node for Structural Health Monitoring,” Sensors, Vol.13, Issue 10, pp. 13204-13216, 2013. https://doi.org/10.3390/s131013204

- [57] J. Zhang, J. Sun, Z. Liu, and G. Zhang, “A flexible calibration method for laser displacement sensors based on a stereo-target,” Measurement Science and Technology, Vol.25, No.10, Article No.105103, 2014. https://doi.org/10.1088/0957-0233/25/10/105103

- [58] T. Siebert, R. Wood, and K. Splitthof, “High speed image correlation for vibration analysis,” J. of Physics: Conf. Series, Vol.181, Article No.012064, 2009. https://doi.org/10.1088/1742-6596/181/1/012064

- [59] Z. Aliansyah, K. Shimasaki, T. Senoo, I. Ishii, and S. Umemoto, “Single-Camera-Based Bridge Structural Displacement Measurement with Traffic Counting,” Sensors, Vol.21, Issue 13, Article No.4517, 2021. https://doi.org/10.3390/s21134517

- [60] S. Caliskan and H. Akyuz, “Investigation of the speckle pattern effect for displacement assessments by DIC,” J. of Intelligent Manufacturing and Special Equipment, Vol.5, Issue 2, pp. 245-254, 2024. https://doi.org/10.1108/JIMSE-01-2024-0002

- [61] K. Murakami, S. Huang, M. Ishikawa, and Y. Yamakawa, “Fully Automated Bead Art Assembly for Smart Manufacturing Using Dynamic Compensation Approach,” J. Robot. Mechatron., Vol.34, No.5, pp. 936-945, 2022. https://doi.org/10.20965/jrm.2022.p0936

- [62] P. Righettini, R. Strada, F. Cortinovis, F. Tabaldi, J. Santinelli, and A. Ginammi, “An Experimental Investigation of the Dynamic Performances of a High Speed 4-DOF 5R Parallel Robot Using Inverse Dynamics Control,” Robotics, Vol.13, Issue 3, Article No.54, 2024. https://doi.org/10.3390/robotics13030054

- [63] A. Davidovic, E. H. Huntington, and M. R. Frater, “Experimental investigation of signal-to-noise ratio gain and stochastic resonance for filtered signals in static nonlinearities,” 2008 2nd Int. Conf. on Signal Processing and Communication Systems, 2008. https://doi.org/10.1109/ICSPCS.2008.4813763

- [64] J. Swevers, W. Verdonck, and J. De Schutter, “Dynamic Model Identification for Industrial Robots,” IEEE Control Systems Magazine, Vol.27, Issue 5, pp. 58-71, 2007. https://doi.org/10.1109/MCS.2007.904659

- [65] R. Sagawa, Y. Higuchi, R. Furukawa, and H. Kawasaki, “Acquisition and Visualization of Micro-Vibration of a Sound Wave in 3D Space,” J. Robot. Mechatron., Vol.34, No.5, pp. 1024-1032, 2022. https://doi.org/10.20965/jrm.2022.p1024

- [66] A. Godil, R. Bostelman, K. S. Saidi, W. P. Shackleford, G. S. Cheok, M. Shneier, and T. Hong, “3D Ground-Truth Systems for Object/Human Recognition and Tracking,” 2013 IEEE Conf. on Computer Vision and Pattern Recognition Workshops, pp. 719-726, 2013. https://doi.org/10.1109/CVPRW.2013.109

- [67] R. Dhaouadi and I. Hafez, “Identification of Shaft Stiffness and Inertias in Flexible Drive Systems,” J. Robot. Mechatron., Vol.35, No.1, pp. 212-217, 2023. https://doi.org/10.20965/jrm.2023.p0212

- [68] D. A. De Souza, J. G. Batista, F. J. S. Vasconcelos, L. L. N. Dos Reis, G. F. Machado, J. R. Costa, J. N. N. Junior, J. L. N. Silva, C. S. N. Rios, and A. B. S. Júnior, “Identification by Recursive Least Squares with Kalman Filter (RLS-KF) Applied to a Robotic Manipulator,” IEEE Access, Vol.9, pp. 63779-63789, 2021. https://doi.org/10.1109/ACCESS.2021.3074419

- [69] J. Swevers, C. Ganseman, J. De Schutter, and H. Van Brussel, “Generation of Periodic Trajectories for Optimal Robot Excitation,” J. of Manufacturing Science and Engineering, Vol.119, Issue 4A, pp. 611-615, 1997. https://doi.org/10.1115/1.2831194

- [70] A. Stenman, F. Gustafsson, D. E. Rivera, L. Ljung, and T. McKelvey, “On adaptive smoothing of empirical transfer function estimates,” Control Engineering Practice, Vol.8, Issue 11, pp. 1309-1315, 2000. https://doi.org/10.1016/S0967-0661(00)00065-4

- [71] Z. Li, S. Zhen, B. Chen, M. Li, R. Liu, and B. Yu, “Lissajous figures in the application of micro-vibration measurement,” Optics Communications, Vol.281, Issue 18, pp. 4744-4746, 2008. https://doi.org/https://doi.org/10.1016/j.optcom.2008.05.049

- [72] C. A. Sierra, “Recurrence in Lissajous Curves and the Visual Representation of Tuning Systems,” Foundations of Science, Vol.30, pp. 271-279, 2023. https://doi.org/10.1007/s10699-023-09930-z

- [73] M. Van Damme, P. Beyl, B. Vanderborght, V. Grosu, R. Van Ham, I. Vanderniepen, A. Matthys, and D. Lefeber, “Estimating robot end-effector force from noisy actuator torque measurements,” 2011 IEEE Int. Conf. on Robotics and Automation, pp. 1108-1113, 2011. https://doi.org/10.1109/ICRA.2011.5980210

- [74] M. Shahbaznia, M. R. Dehkordi, and A. Mirzaee, “An Improved Time-Domain Damage Detection Method for Railway Bridges Subjected to Unknown Moving Loads,” Periodica Polytechnica Civil Engineering, Vol.64, No.3, pp. 928-938, 2020. https://doi.org/10.3311/PPci.15813

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.