Research Paper:

Intelligent Prediction of Uniaxial Compressive Strength Based on Multi-Source Information Fusion

Quanxin Li*,**, Hongbo Dong*,**, Youzhen Zhang*,**,†, Jun Fang*,**, and Wangnian Li*,***

*China Coal Technology Engineering Group (CCTEG) Xi’an Research Institute (Group) Co., Ltd.

No.82 Jinye 1st Road, Gaoxin District, Xi’an, Shaanxi 710077, China

**China Coal Research Institute

No.5 Qingniangou East Road, Hepingli, Chaoyang District, Beijing 100013, China

***School of Automation, China University of Geosciences

No.388 Lumo Road, Hongshan District, Wuhan 430074, China

†Corresponding author

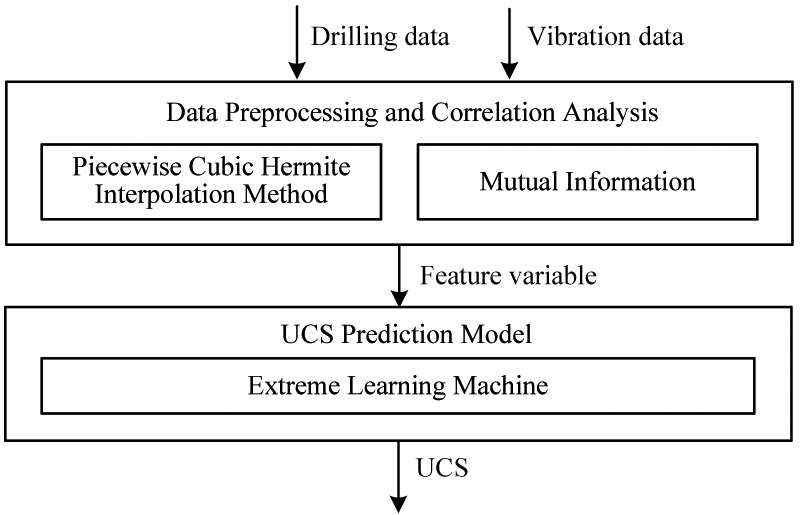

Uniaxial compressive strength (UCS) is a fundamental indicator of formation hardness, playing a vital role in evaluating geomechanical properties during drilling process. Accurate UCS prediction enables real-time assessment of formation conditions, contributing to improved drilling safety and efficiency. This study proposes a multi-source data fusion approach that integrates vibration data with conventional drilling parameters to enhance UCS prediction accuracy. To address the inconsistency in time scales between the two data sources, a piecewise cubic Hermite interpolation method is applied for temporal alignment. The fused dataset is then used to retrain an extreme learning machine model. Experimental validation is conducted using data collected from a surface drilling test site. Results demonstrate that the proposed method significantly outperforms single-source prediction models, highlighting the effectiveness of vibration-assisted data fusion in real-time UCS estimation.

Uniaxial compressive strength prediction scheme

- [1] Y. Yao, N. Yao, C. Liang, H. Wei, H. Song, and L. Wang, “Accurate measurement method of drilling depth based on multi-sensor data fusion,” J. Adv. Comput. Intell. Intell. Inform., Vol.26, No.3, pp. 367-374, 2022. https://doi.org/10.20965/jaciii.2022.p0367

- [2] H. Wei, N. Yao, H. Tian, Y. Yao, J. Zhang, and H. Li, “A predicting model for near-horizontal directional drilling path based on bp neural network in underground coal mine,” J. Adv. Comput. Intell. Intell. Inform., Vol.26, No.3, pp. 279-288, 2022. https://doi.org/10.20965/jaciii.2022.p0279

- [3] V. Palchik, “Influence of porosity and elastic modulus on uniaxial compressive strength in soft brittle porous sandstones,” Rock Mechanics and Rock Engineering, Vol.32, No.4, pp. 303-309, 1999. https://doi.org/10.1007/s006030050050

- [4] A. Tuğrul and I. Zarif, “Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from turkey,” Engineering Geology, Vol.51, No.4, pp. 303-317, 1999. https://doi.org/10.1016/S0013-7952(98)00071-4

- [5] M. Karakus and B. Tutmez, “Fuzzy and multiple regression modelling for evaluation of intact rock strength based on point load, schmidt hammer and sonic velocity,” Rock Mechanics and Rock Engineering, Vol.39, pp. 45-57, 2006. https://doi.org/10.1007/s00603-005-0050-y

- [6] S. Yagiz, “Correlation between slake durability and rock properties for some carbonate rocks,” Bulletin of Engineering Geology and the Environment, Vol.70, pp. 377-383, 2011. https://doi.org/10.1007/s00603-005-0050-y

- [7] N. Zhang, Y. Zhang, and K. Yao, “An optimized identification method of coal-bearing stratum lithology,” J. of Mine Automation, Vol.46, No.7, pp. 100-106, 2020. https://doi.org/10.13272/j.issn.1671-251x.2020010037

- [8] Z. Liu, D. Li, Y. Liu, B. Yang, and Z. Zhang, “Prediction of uniaxial compressive strength of rock based on lithology using stacking models,” Rock Mechanics Bulletin, Vol.2, No.4, Article No.100081, 2023. https://doi.org/10.1016/j.rockmb.2023.100081

- [9] C. Jia, F. Chen, M. Lei, J. Huang, C. Shi, and D. Liu, “Determination method of rock strength based on digital drilling parameters,” J. of Southwest Jiaotong University, Vol.60, pp. 1-10, 2024. https://doi.org/10.3969/j.issn.0258-2724.20230328

- [10] N. Klyuchnikov, A. Zaytsev, A. Gruzdev, G. Ovchinnikov, K. Antipova, L. Ismailova, E. Muravleva, E. Burnaev, A. Semenikhin, A. Cherepanov et al., “Data-driven model for the identification of the rock type at a drilling bit,” J. of Petroleum Science and Engineering, Vol. 178, pp. 506-516, 2019. https://doi.org/10.1016/j.petrol.2019.03.041

- [11] H. Yang, S. Zhang, J. Qin, and Y. Yuan, “Identification technology of coalbed methane horizontal well while drilling based on multi-information integration,” Coal Science and Technology, No.5, 2016. https://doi.org/10.13199/j.cnki.cst.2016.05.020

- [12] J. Qiu, X. Yin, Y. Pan, X. Wang, and M. Zhang, “Prediction of uniaxial compressive strength in rocks based on extreme learning machine improved with metaheuristic algorithm,” Mathematics, Vol.10, No.19, Article No.3490, 2022. https://doi.org/10.3390/math10193490

- [13] X. Shi, G. Liu, X. Gong, J. Zhang, J. Wang, and H. Zhang, “An efficient approach for real-time prediction of rate of penetration in offshore drilling,” Mathematical Problems in Engineering, Vol. 2016, No.1, Article No.3575380, 2016. https://doi.org/10.1155/2016/3575380

- [14] Y. Xu, D. Zhang, T. Xian, Z. Ma, H. Gao, and Y. Ma, “Two-direction prediction method of drilling fluid based on os-elm for water well drilling,” J. Adv. Comput. Intell. Intell. Inform., Vol.27, No.4, pp. 594-602, 2023. https://doi.org/10.20965/jaciii.2023.p0594

- [15] C. Gan, W. Cao, M. Wu, K. Liu, X. Chen, Y. Hu, and F. Ning, “Two-level intelligent modeling method for the rate of penetration in complex geological drilling process,” Applied Soft Computing, Vol.80, pp. 592-602, 2019. https://doi.org/10.1016/j.asoc.2019.04.020

- [16] X. Yang, M. Wu, C. Lu, W. Li, L. Chen, and S. Du, “Prediction of rate of penetration based on drilling conditions identification for drilling process,” Neurocomputing, Vol.579, Article No.127439, 2024. https://doi.org/10.1016/j.neucom.2024.127439

- [17] C. Gan, W. Cao, L. Wang, K. Liu, and M. Wu, “An improved dynamic optimization control system for the drilling rate of penetration (rop) and its industrial application,” IEEE Trans. on Industrial Electronics, Vol.70, No.6, pp. 6201-6208, 2022. https://doi.org/10.1109/TIE.2022.3199916

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.