Research Paper:

Prediction of Rate of Penetration in Drilling Process with Bayesian-Optimized Gaussian Process Regression

Kanghui Zeng*1,*2,*3

, Min Wu*1,*2,*3,*4,†

, Min Wu*1,*2,*3,*4,†

, Chengda Lu*2,*3,*4

, Chengda Lu*2,*3,*4

, Xiao Yang*1,*2,*3

, Xiao Yang*1,*2,*3

, and Zhejiaqi Ma*2,*3,*4

, and Zhejiaqi Ma*2,*3,*4

*1School of Future Technology, China University of Geosciences

No.388 Lumo Road, Hongshan District, Wuhan, Hubei 430074, China

*2Hubei Key Laboratory of Advanced Control and Intelligent Automation for Complex Systems

No.388 Lumo Road, Hongshan District, Wuhan, Hubei 430074, China

*3Engineering Research Center of Intelligent Technology for Geo-Exploration, Ministry of Education

No.388 Lumo Road, Hongshan District, Wuhan, Hubei 430074, China

*4School of Automation, China University of Geosciences

No.388 Lumo Road, Hongshan District, Wuhan 430074, China

†Corresponding author

Predicting the rate of penetration (ROP) is essential for improving drilling efficiency by optimizing the operational parameters. Accurate ROP prediction facilitates better decision-making, reduces drilling costs, and helps obtain optimal operational parameters. This paper proposes a new prediction model that combines Gaussian process regression and Bayesian optimization methods. First, the interquartile range and Savitzky-Golay filtering methods are used to denoise the data. To reduce model redundancy, appropriate input variables are identified based on Spearman correlation analysis. Second, a Gaussian process regression model tuned using Bayesian optimization is established to predict the ROP. Finally, public data sourced from the UTAH FORGE Well 58-32 dataset are used to validate the proposed model. The results indicate that the proposed model offers reliable prediction accuracy and enhances the ROP during drilling.

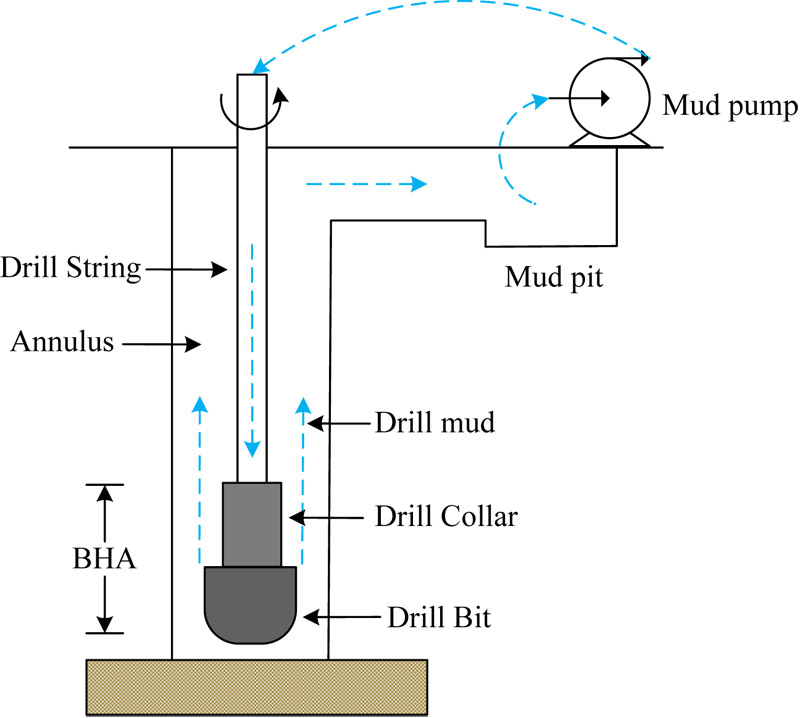

Geological drilling process

- [1] C. Soares and K. Gray, “Real-time predictive capabilities of analytical and machine learning rate of penetration (rop) models,” J. of Petroleum Science and Engineering, Vol.172, pp. 934-959, 2019. https://doi.org/10.1016/j.petrol.2018.08.083

- [2] L. F. F. Barbosa, A. Nascimento, M. H. Mathias, and J. A. de Carvalho, “Machine learning methods applied to drilling rate of penetration prediction and optimization – A review,” J. of Petroleum Science and Engineering, Vol.183, Article No.106332, 2019. https://doi.org/10.1016/j.petrol.2019.106332

- [3] C. Hegde, H. Daigle, H. Millwater, and K. Gray, “Analysis of rate of penetration (rop) prediction in drilling using physics-based and data-driven models,” J. of Petroleum Science and Engineering, Vol.159, pp. 295-306, 2017. https://doi.org/10.1016/j.petrol.2017.09.020

- [4] A. T. Bourgoyne, Jr. and F. S. Young, Jr., “A multiple regression approach to optimal drilling and abnormal pressure detection,” Society of Petroleum Engineers J., Vol.14, No.4, pp. 371-384, 1974. https://doi.org/10.2118/4238-PA

- [5] A. Negara and B. Saad, “Combining insight from physics-based models into data-driven model for predicting drilling rate of penetration,” IPTC Int. Petroleum Technology Conf., pp. 5-9, 2020. https://doi.org/10.2523/IPTC-20090-MS

- [6] X. Liao, M. Khandelwal, H. Yang, M. Koopialipoor, and R. Bhatawdekar, “Effects of a proper feature selection on prediction and optimization of drilling rate using intelligent techniques,” Engineering with Computers, Vol.36, pp. 499-510, 2020. https://doi.org/10.1007/s00366-019-00711-6

- [7] M. Bataee, S. Irawan, and M. Kamyab, “Artificial neural network model for prediction of drilling rate of penetration and optimization of parameters,” J. of the Japan Petroleum Institute, Vol.57, No.2, pp. 65-70, 2014. https://doi.org/10.1627/jpi.57.65

- [8] M. R. Delavar, A. Ramezanzadeh, R. Gholami, and M. Sanei, “Optimization of drilling parameters using combined multi-objective method and presenting a practical factor,” Computers & Geosciences, Vol.175, Article No.105359, 2023. https://doi.org/10.1016/j.cageo.2023.105359

- [9] X. Yang, M. Wu, C. Lu, W. Li, L. Chen, and S. Du, “Prediction of rate of penetration based on drilling conditions identification for drilling process,” Neurocomputing, Vol.579, Article No.127439, 2024. https://doi.org/10.1016/j.neucom.2024.127439

- [10] C. Gan, W.-H. Cao, M. Wu, X. Chen, Y.-L. Hu, K.-Z. Liu, F.-W. Wang, and S.-B. Zhang, “Prediction of drilling rate of penetration (rop) using hybrid support vector regression: A case study on the shennongjia area, central china,” J. of Petroleum Science and Engineering, Vol.181, Article No.106200, 2019. https://doi.org/10.1016/j.petrol.2019.106200

- [11] O. S. Ahmed, A. A. Adeniran, and A. Samsuri, “Computational intelligence based prediction of drilling rate of penetration: A comparative study,” J. of Petroleum Science and Engineering, Vol.172, pp. 1-12, 2019. https://doi.org/10.1016/j.petrol.2018.09.027

- [12] Y. Alali, F. Harrou, and Y. Sun, “Optimized gaussian process regression by bayesian optimization to forecast covid-19 spread in india and brazil: A comparative study,” 2021 Int. Conf. on ICT for Smart Society (ICISS), 2021. https://doi.org/10.1109/ICISS53185.2021.9532501

- [13] E. Y. Kaya, I. Ali, Z. Ceylan, and S. Ceylan, “Prediction of higher heating value of hydrochars using bayesian optimization tuned gaussian process regression based on biomass characteristics and process conditions,” Biomass and Bioenergy, Vol.180, Article No.106993, 2023. https://doi.org/10.1016/j.biombioe.2023.106993

- [14] T. Yehia, M. Gasser, H. Ebaid, N. Meehan, and E. R. Okoroafor, “Comparative analysis of machine learning techniques for predicting drilling rate of penetration (rop) in geothermal wells: A case study of forge site,” Geothermics, Vol.121, Article No.103028, 2024. https://doi.org/10.1016/j.geothermics.2024.103028

- [15] E. Schulz, M. Speekenbrink, and A. Krause, “A tutorial on gaussian process regression: Modelling, exploring, and exploiting functions,” J. of Mathematical Psychology, Vol.85, pp. 1-16, 2018. https://doi.org/10.1016/j.jmp.2018.03.001

- [16] X. Wu, X. Lai, J. Hu, X. Chen, W. Cao, and M. Wu, “Rate of penetration prediction using hybrid gaussian process regression model with ard structure in geological drilling process,” 2022 13th Asian Control Conf. (ASCC), pp. 607-612, 2022. https://doi.org/10.23919/ASCC56756.2022.9828292

- [17] X. Yao and D. Wu, “Prediction of mechanical properties of recycled concrete using bayesian optimization-based gaussian process regression method,” Science Technology and Engineering, Vol.23, No.7, pp. 2968-2975, 2023. https://doi.org/10.12404/j.issn.1671-1815.2023.23.07.02968

- [18] A. M. A. Ben and T. Madarász, “Applying machine learning to predict the rate of penetration for geothermal drilling located in the utah forge site,” Energies, Vol.15, No.12, Article No.4288, 2022. https://doi.org/10.3390/en15124288

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.