Research Paper:

Label Design and Extraction in High-Temperature Logistics Based on Concave Coding and MLFFA-DeepLabV3+ Network

Xiaoyan Zhao*1,*2,†

, Pengfei Zhao*2, Yuguo Yin*3, Luqi Tao*1, Jianfeng Yan*4, and Zhaohui Zhang*1,*2

, Pengfei Zhao*2, Yuguo Yin*3, Luqi Tao*1, Jianfeng Yan*4, and Zhaohui Zhang*1,*2

*1School of Automation and Electrical Engineering, University of Science and Technology Beijing

30 Xueyuan Road, Haidian District, Beijing 100083, China

*2Shunde Innovation School, University of Science and Technology Beijing

2 Zhihui Road, Daliang, Shunde District, Fo Shan, Guangdong 528399, China

*3Shandong Start Measurement and Control Equipment Co., Ltd.

600 Xinyi Road, Weifang Economic Development Zone, Weifang, Shandong 261101, China

*4Future Development Research Center, China Ship Research and Development Academy

2 Shuangquanpu, Chaoyang District, Beijing 100192, China

†Corresponding author

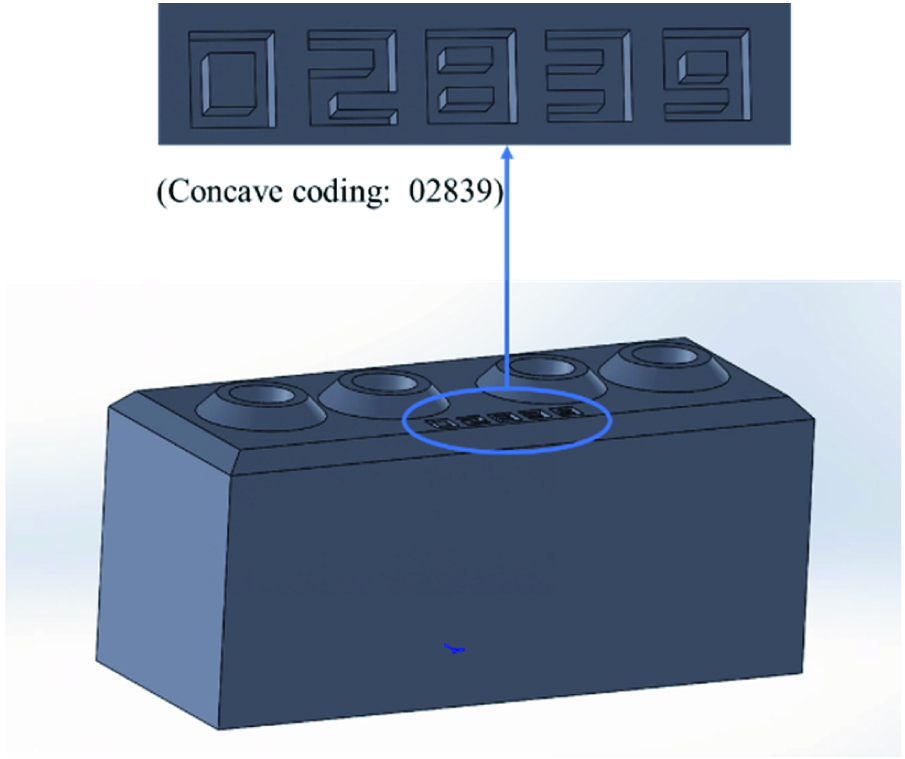

Logistics tracking technology at normal temperature is quite mature, but there are few tracking methods for the high-temperature production process. The main difficulties are that the label materials generally used cannot withstand the high temperature for a long time, and the detection devices are vulnerable to environmental impact. A high-temperature logistics tracking solution was developed for a carbon anode used in an aluminum electrolysis factory. It is based on concave coding and a multiscale low-level feature fusion and attention-DeepLabV3+ (MLFFA-DeepLabV3+) network extraction technique for the coded region of the concave coding. The concave coding is printed on the product as a tag that can endure a high temperature of more than 1,200°C, ensuring its integrity and identifiability. Because there is no obvious color distinction between the coding area and the background, direct recognition is ineffective. The MLFFA-DeepLabV3+ network extracts the coding region to improve the recognition rate. The DeepLabV3+ network is improved by replacing the backbone network and adding of a multiscale low-level feature fusion module and convolutional block attention module. Experimental results showed that the mean pixel accuracy and mean intersection over union of the MLFFA-DeepLabV3+ network increased by 2.37% and 2.45%, respectively, compared with the original DeepLabV3+ network. The network structure has only 11.24% of the number of parameters in the original structure. The solution is feasible and provides a basis for high-temperature logistics tracking technology in intelligent manufacturing.

Concave coding example

- [1] Z. Xu, J. He, and Z. Chen, “Design and actualization of IoT-based intelligent logistics system,” 2012 IEEE Int. Conf. on Industrial Engineering and Engineering Management, pp. 2245-2248, 2012. https://doi.org/10.1109/IEEM.2012.6838146

- [2] R. Want, “An introduction to RFID technology,” IEEE Pervasive Computing, Vol.5, No.1, pp. 25-33, 2006. https://doi.org/10.1109/MPRV.2006.2

- [3] R. Diachok, R. Dunets, and H. Klym, “System of detection and scanning bar codes from Raspberry Pi web camera,” 2018 IEEE 9th Int. Conf. on Dependable Systems, Services and Technologies (DESSERT), pp. 184-187, 2018. https://doi.org/10.1109/DESSERT.2018.8409124

- [4] X. He, “The two-dimensional bar code application in book management,” 2010 Int. Conf. on Web Information Systems and Mining, pp. 409-411, 2010. https://doi.org/10.1109/WISM.2010.58

- [5] E. Mayer et al., “Characterization of langasite as a material for SAW based RFID and sensing systems at high temperatures,” 2009 IEEE MTT-S Int. Microwave Workshop on Wireless Sensing, Local Positioning, and RFID, 2009. https://doi.org/10.1109/IMWS2.2009.5307882

- [6] V. Franchina et al., “A compact UHF RFID ceramic tag for high-temperature applications,” 2019 IEEE Int. Conf. on RFID Technology and Applications (RFID-TA), pp. 480-483, 2019. https://doi.org/10.1109/RFID-TA.2019.8892217

- [7] M. S. Reynolds, “A 500°C tolerant ultra-high temperature 2.4 GHz 32 bit chipless RFID tag with a mechanical BPSK modulator,” 2017 IEEE Int. Conf. on RFID, pp. 144-148, 2017. https://doi.org/10.1109/RFID.2017.7945600

- [8] A. Ria et al., “Performance analysis of a compact UHF RFID ceramic tag in high-temperature environments,” IEEE J. of Radio Frequency Identification, Vol.4, No.4, pp. 461-467, 2020. https://doi.org/10.1109/JRFID.2020.2998008

- [9] L. Perez and J. Wang, “The effectiveness of data augmentation in image classification using deep learning,” arXiv: 1712.04621, 2017. https://doi.org/10.48550/arXiv.1712.04621

- [10] L.-C. Chen et al., “Encoder-decoder with atrous separable convolution for semantic image segmentation,” Proc. of the 15th European Conf. on Computer Vision (ECCV 2018), pp. 833-851, 2018. https://doi.org/10.1007/978-3-030-01234-2_49

- [11] M. Sandler et al., “MobileNetV2: Inverted residuals and linear bottlenecks,” 2018 IEEE/CVF Conf. on Computer Vision and Pattern Recognition (CVPR), pp. 4510-4520, 2018. https://doi.org/10.1109/CVPR.2018.00474

- [12] X. Zhao et al., “Cross-view gait recognition based on dual-stream network,” J. Adv. Comput. Intell. Intell. Inform., Vol.25, No.5, pp. 671-678, 2021. https://doi.org/10.20965/jaciii.2021.p0671

- [13] S. Woo et al., “CBAM: Convolutional block attention module,” Proc. of the 15th ECCV 2018, pp. 3-19, 2018. https://doi.org/10.1007/978-3-030-01234-2_1

- [14] J. P. Rogelio et al., “Object detection and segmentation using Deeplabv3 deep neural network for a portable X-ray source model,” J. Adv. Comput. Intell. Intell. Inform., Vol.26, No.5, pp. 842-850, 2022. https://doi.org/10.20965/jaciii.2022.p0842

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.